High-frequency flat-panel transformer

A flat-panel transformer, high-frequency technology, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., to achieve the effect of reduced volume, low loss, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

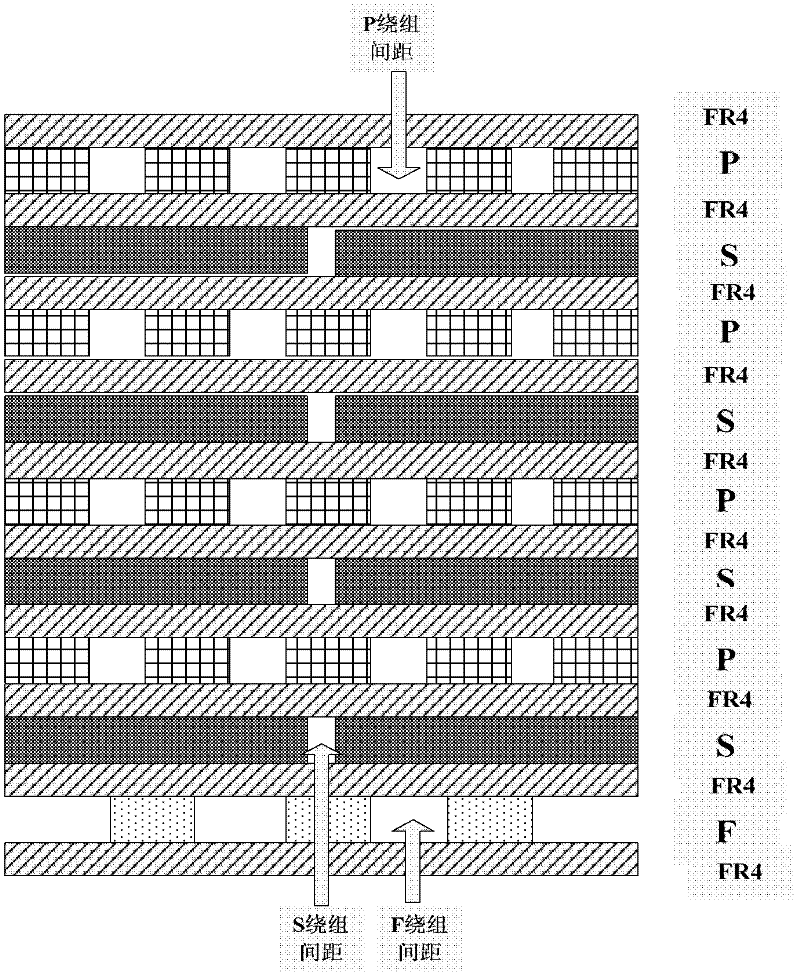

[0031] like figure 2 The schematic diagram of the flat transformer winding structure of the present invention is shown, wherein P represents the primary winding, S represents the secondary winding, F represents the auxiliary power winding (feedback winding), and FR4 is the insulating medium layer. Since each turn of winding needs to be electrically isolated, the P winding spacing, S winding spacing and F auxiliary power winding spacing are set (as indicated by the arrows in the figure). The winding adopts interlaced winding technology, and the primary side and secondary side are interleaved in layout, the purpose of which is to reduce the AC distribution parameters.

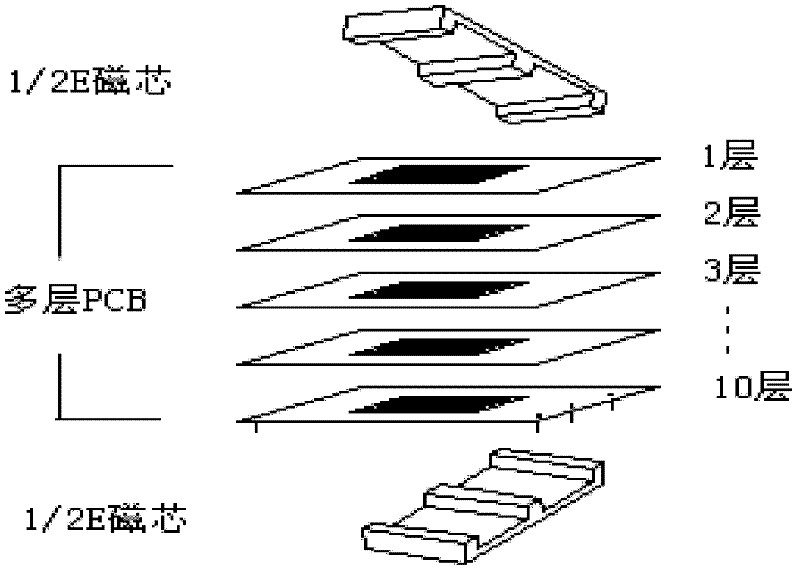

[0032] image 3 A schematic diagram of the planar transformer structure and process is given, in which the planar transformer is composed of 10-layer PCB and lead-out pins, with a thickness of 3mm. Two flat E-shaped ferrite cores (1 / 2E) are respectively assembled (with crimped) on both sides of the flat windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com