Fuel cell assembly and vehicle

A technology of fuel cell and fuel cell unit, which is applied in the field of vehicles and can solve problems such as deterioration of fuel utilization rate, increased component weight, and fuel gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0059] Embodiment 1 of the present invention relates to a fuel cell module in which fuel cell units individually housing a fuel cell stack are provided in a protective structure. In Embodiment 1, a fuel cell system including a fuel cell module is mounted on a vehicle (fuel cell vehicle). Hereinafter, first, the structure of the fuel cell system will be described, and then details of the fuel cell module will be described.

[0060] (system structure)

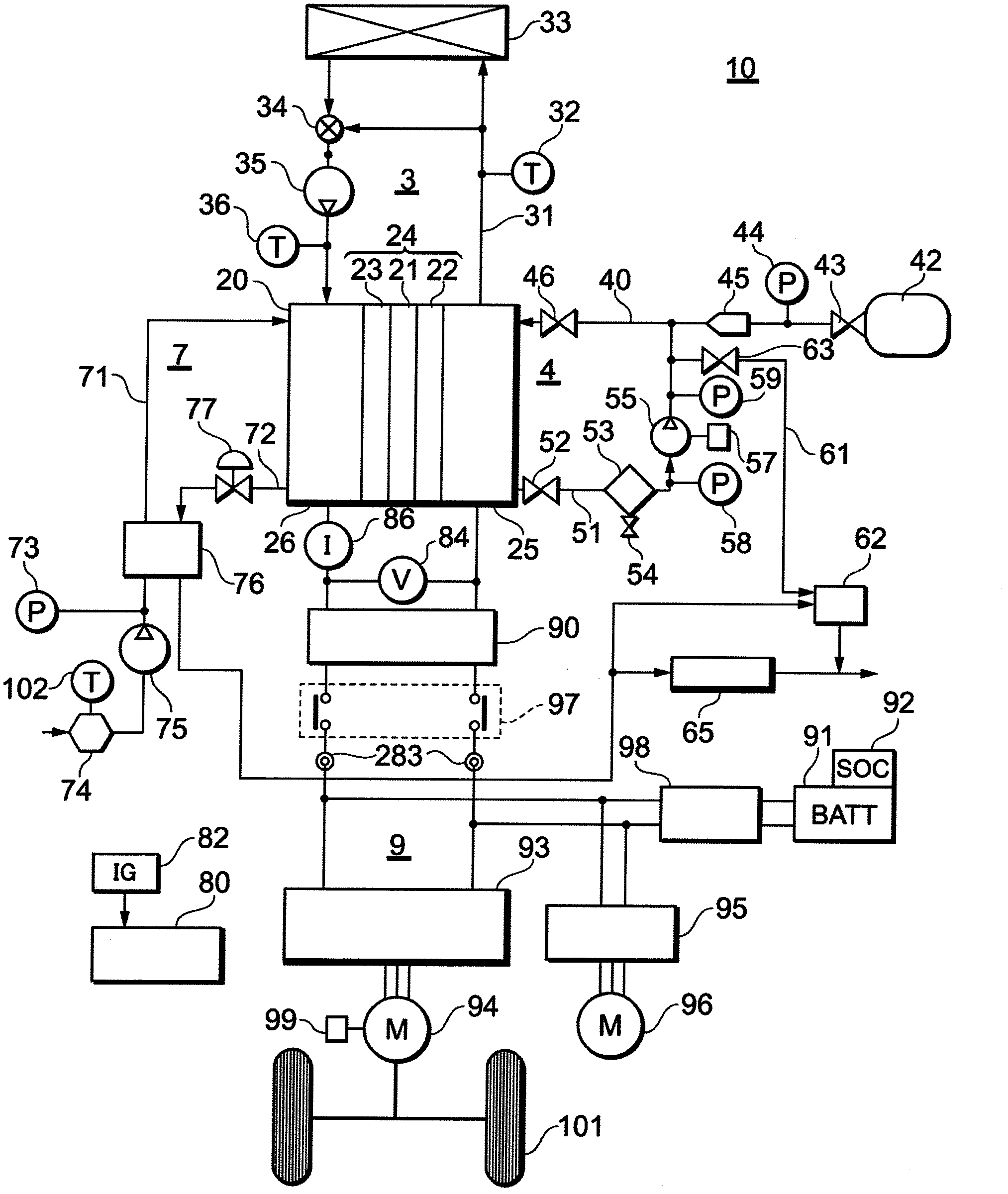

[0061] figure 1 It is a structural diagram of a fuel cell system to which the present invention is applied.

[0062] figure 1 The fuel cell system 10 includes a fuel gas supply system 4 , an oxidizing gas supply system 7 , a coolant supply system 3 , and an electric power system 9 . The fuel gas supply system 4 is a system for supplying fuel gas (hydrogen gas) to the fuel cell 20 . The oxidizing gas supply system 7 is a system for supplying oxidizing gas (air) to the fuel cell 20 . The coolant supply system 3 is a system fo...

Embodiment approach 2

[0155] Embodiment 2 of the present invention relates to a modified example of the fuel cell module.

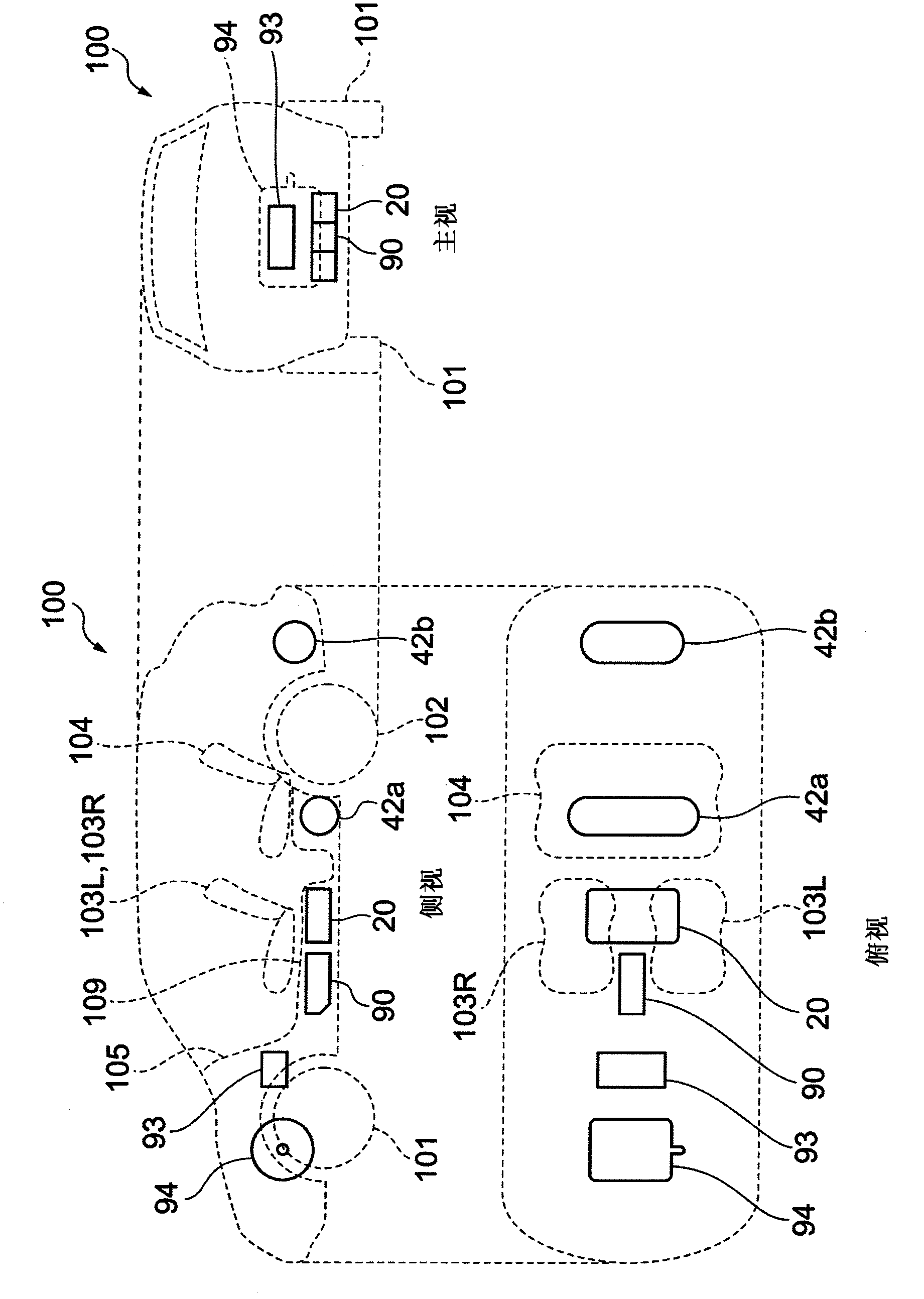

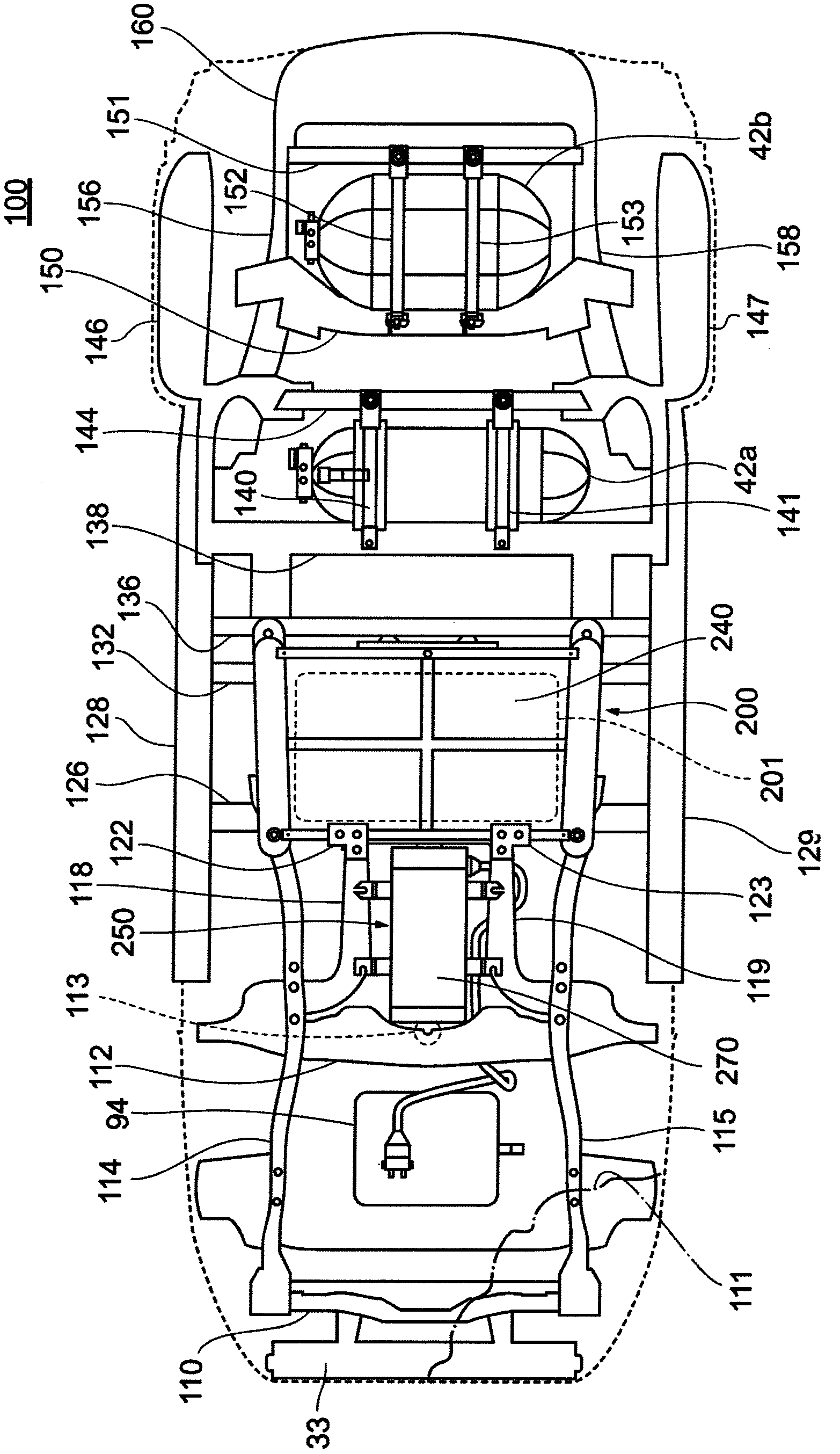

[0156] Figure 11 A perspective view showing the fuel cell module 300 in the second embodiment. Figure 12 A vehicle side view illustrating the arrangement of the fuel cell assembly 300 in Embodiment 2 is shown. Figure 13 A bottom view of a vehicle showing the arrangement of the fuel cell assembly 300 in the second embodiment.

[0157] like Figure 11 and Figure 13 As shown, the fuel cell assembly 300 of the second embodiment is configured by arranging a plurality of fuel cell-related devices, here, the fuel cell unit 201 and the FC converter 90 along the width direction of the vehicle. However, the fuel cell-related devices are not limited to this combination, and other devices related to an inverter may be provided together with the fuel cell unit 201 . The protective structure 310 is formed in a size and shape capable of housing the fuel cell unit 201 and the FC conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com