Friction clutch

A technology of friction clutch and friction clutch, which is applied in the field of clutches, can solve problems such as low friction coefficient, not necessarily able to provide performance, excellent friction disc, etc., and achieve high friction coefficient, stable torque transmission, and the effect of wear suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101~110

[0092] A CC composite material is used as the carbon / graphite material, and a steel material is used as the metal / ceramic material. Furthermore, the area ratio a of the friction surface was changed from 3% to 75%, and ten types of friction disk assemblies as Examples 101 to 110 were prepared. Table 1 shows a list of the above samples.

[0093] [Table 1]

[0094] Table 1 Material composition of the clutch friction surface used in the test (Part 1)

[0095]

Embodiment 201~210

[0097]A CC composite material was used as the carbon / graphite material, and brass was used as the metal / ceramic material. Furthermore, as in the case of Examples 101 to 110, the area ratio a of the friction surface was changed from 3% to 75%, and ten types of friction disk assemblies as Examples 201 to 210 were prepared. Table 2 shows a list of the above samples.

[0098] [Table 2]

[0099] Table 2 Material composition of the clutch friction surface used in the test (Part 2)

[0100]

Embodiment 301~310

[0102] A CC composite material is used as the carbon / graphite material, and copper is used as the metal / ceramic material. Furthermore, as in the case of Examples 101 to 110, the area ratio a of the friction surface was changed from 3% to 75%, and ten types of friction disk assemblies as Examples 301 to 310 were prepared. Table 3 shows a list of the above samples.

[0103] [table 3]

[0104] Table 3 Material composition of the clutch friction surface used in the test (Part 3)

[0105]

[0106] In addition, various factors of the friction disk assembly used here are as follows.

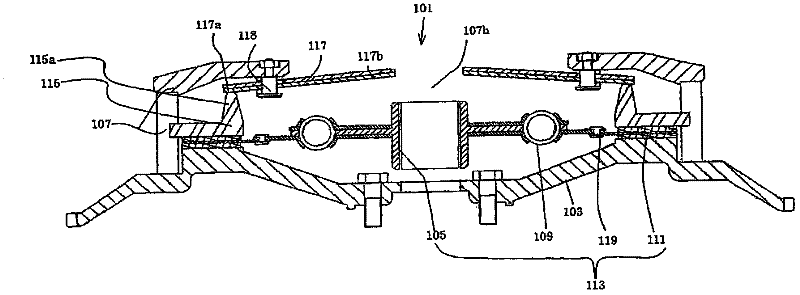

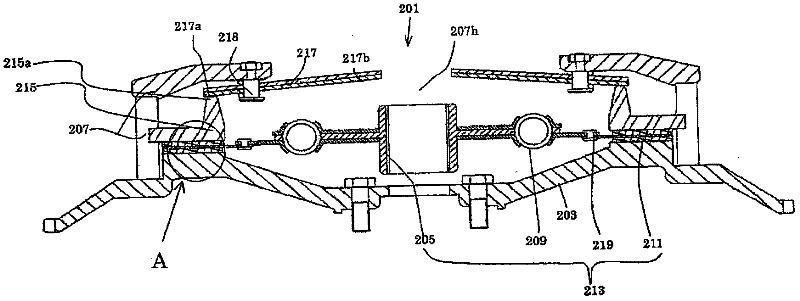

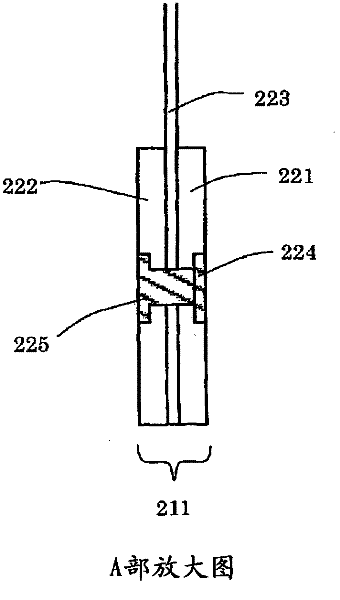

[0107] The shape of the friction disc assembly: such as figure 2 , 3 , the form shown in 5

[0108] The shape of the friction plate: it is divided into 3 parts on the circumference, fan shape

[0109] Outer diameter: 240mm

[0110] Inside diameter: 160mm

[0111] Friction disc thickness: 7.8mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com