Mechanism for intelligently controlling moving head of multi-station material forming machine to rotate

A technology of intelligent control and moving head, which is applied in the direction of metal processing, etc., can solve the problems of slow speed, non-rotating moving head of four-column cutting machine, high labor intensity and safety performance, etc., and achieve high punching efficiency, easy and convenient knife die movement, The effect of improving work efficiency and blanking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

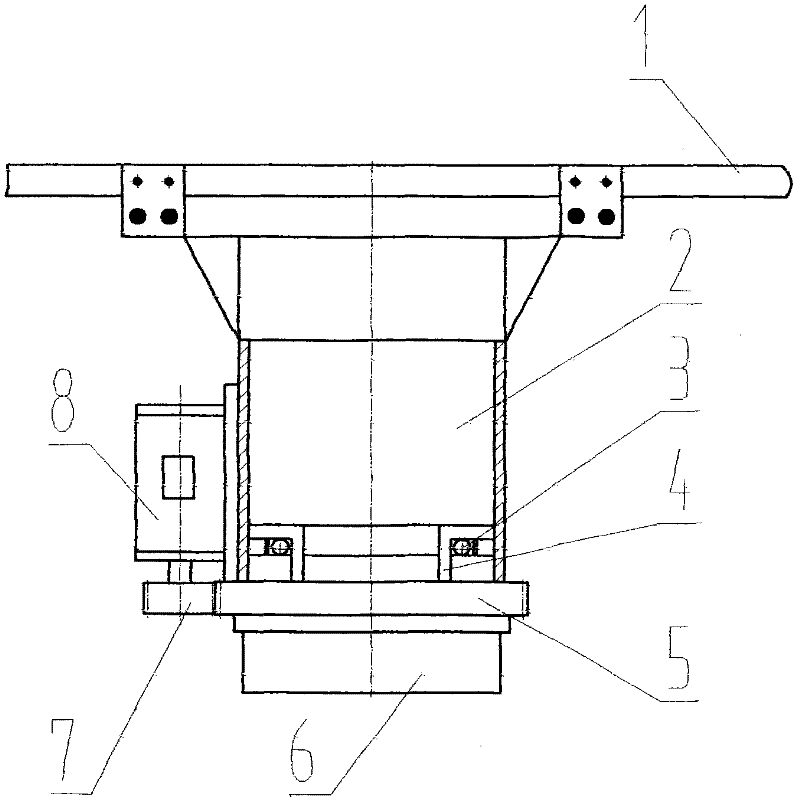

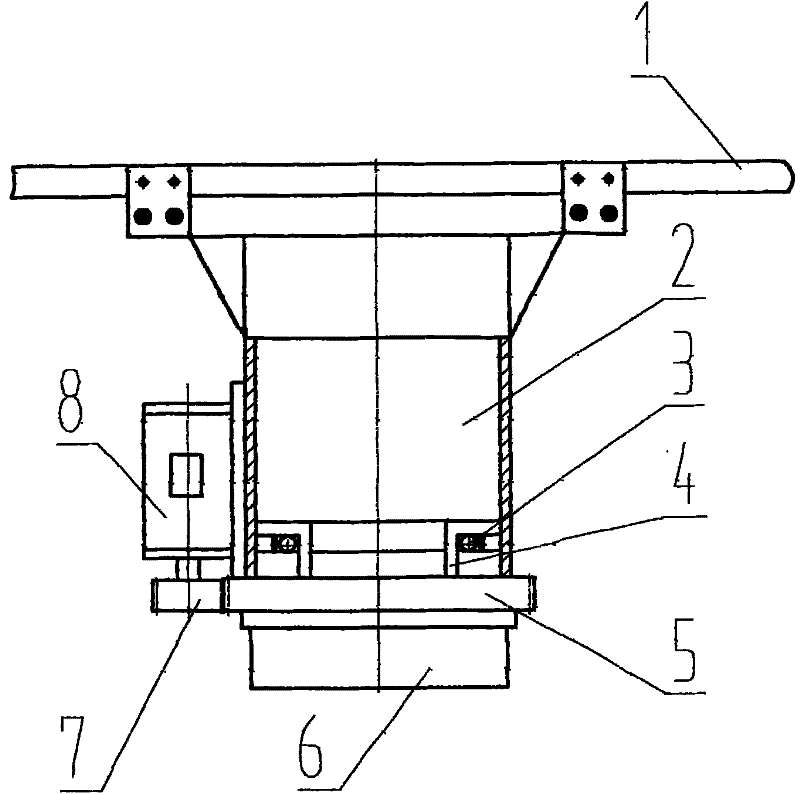

[0009] The present invention is mainly composed of a translation guide rail 1, a moving head body 2, a plane bearing 3, a connecting shaft 4, a main transmission gear 5, a die fixing frame 6, a motor gear 7, and a servo motor 8. The translation guide rail 1 is installed at the lower end of the upper body On both sides, the moving head body 2 is installed at the lower ends of the translation guide rails 1 on both sides. The moving head body 2 is welded by steel plates, and the plane bearing 3 is installed inside, which is connected by the connecting shaft 4. The main transmission gear 5 is fixed at the lower end of the connecting shaft 4. The lower end of the gear 5 is equipped with a die holder 6, the side of the moving head body 2 is equipped with a servo motor 8, and the lower end of the servo motor 8 is equipped with a motor gear 7, which cooperates with the main transmission gear 5, and the motor gear 7 drives the main transmission gear 5 The rotation drives the die holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com