Water processor with siamesed filtration tank and underslung machine base

A technology for water processors and machine bases, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Popularization and other issues, to achieve the effect of avoiding inconvenience and service expenses, stable assembly quality, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

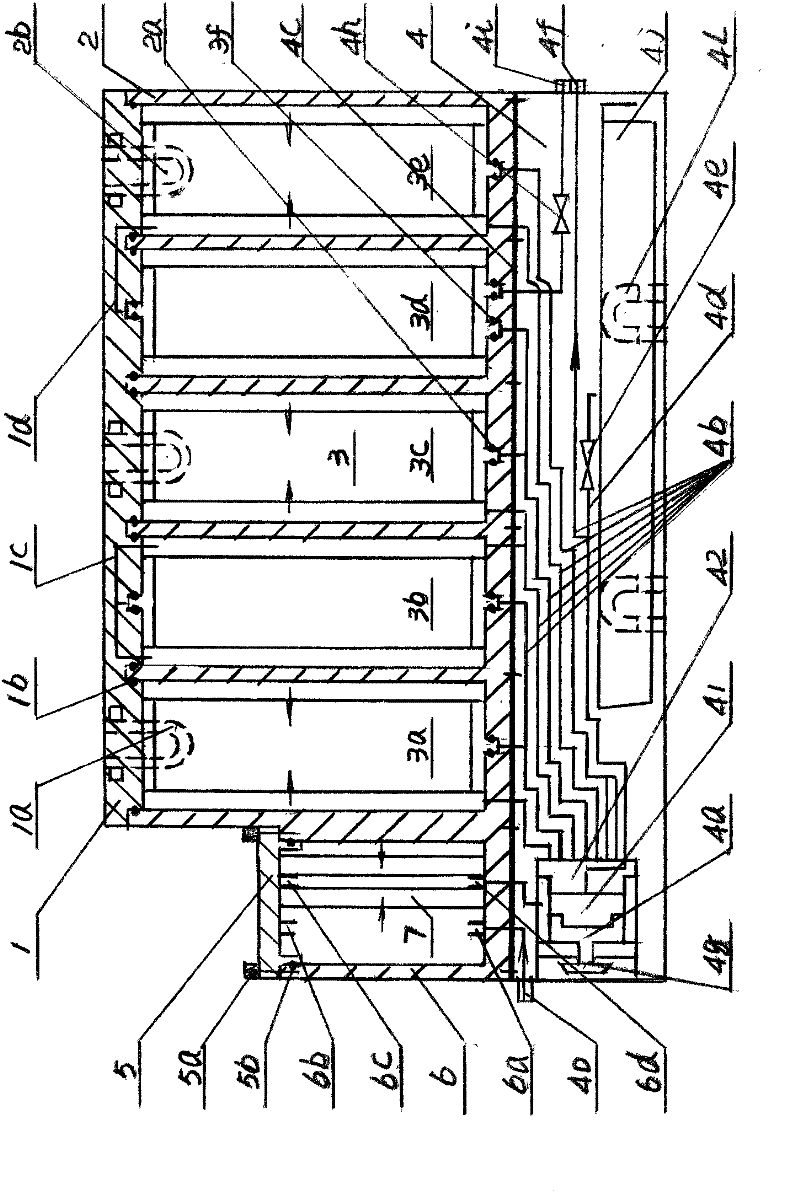

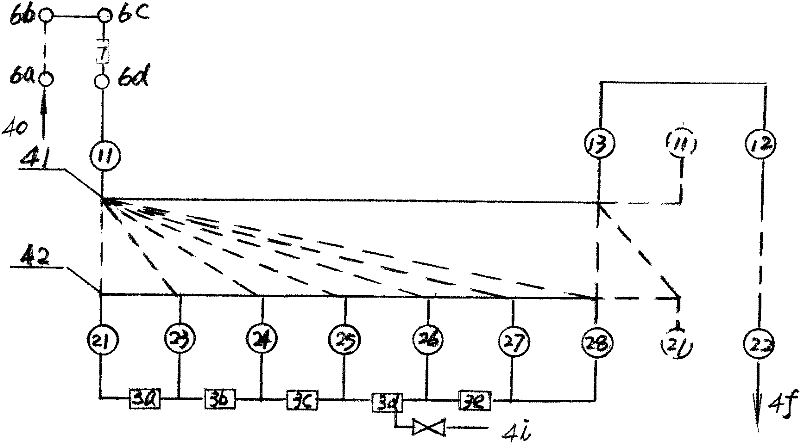

[0025] figure 1 , 2 The combination of structures shows the best mode of the present invention. A lower seal 4c is placed between the one-piece filter chamber 2 and the lower machine base 4, and is sealed and connected by fasteners. Put the waterway switcher 4a into the side mounting chamber of the lower machine base 4 and then seal and fix it. The front two-position filter chamber 6 is integrated with the five-position conjoined filter chamber 2, and two water outlets 6a and 6d are arranged at the bottom to seal with the water inlet pipe interface 4o of the lower machine base and the water inlet 11 of the water circuit switcher 4a respectively connect. Insert the annular cylindrical PPf fiber bare bladder 7 into the socket 6d, insert the front cover 5, and connect and fix it with the fastener 5a. At this time, the upper end of the annular cylindrical PPf fiber bare bladder 7 is plugged into the socket 6c of the front cover 5 . Insert five built-in plug-in filters in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com