Two-step molding method of thin plate glass pre-pressing

A molding method, glass technology, used in glass molding, glass rolling, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

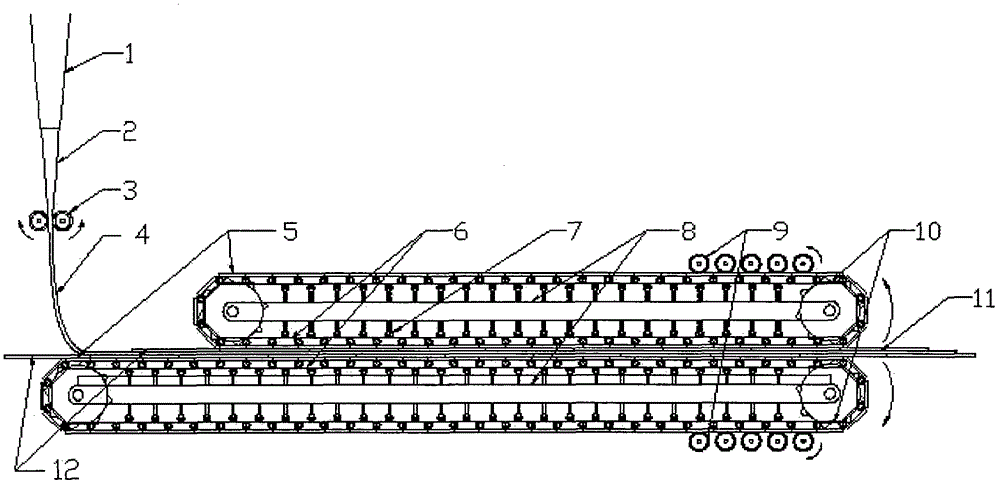

specific Embodiment approach 2

Specific implementation mode 2

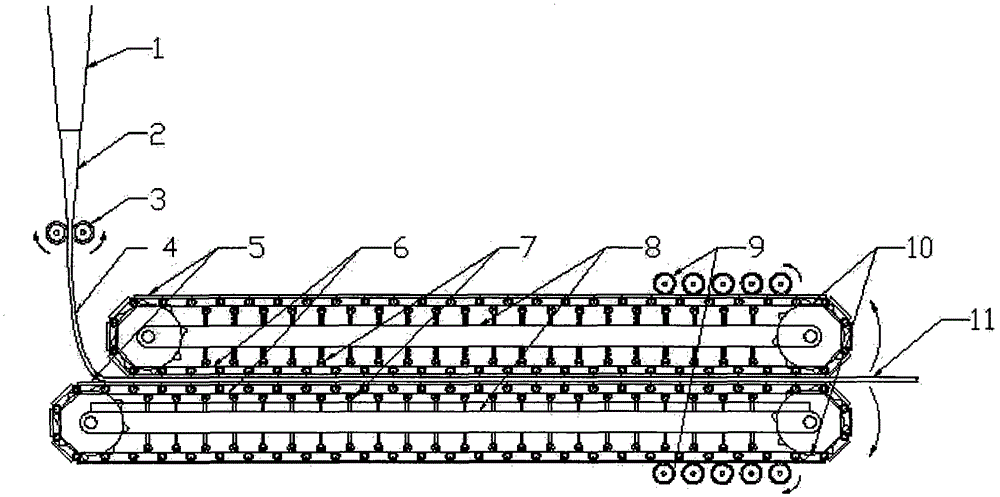

[0012] The high-temperature molten glass ribbon 2 flowing out of the glass outlet 1 of the melting furnace is rolled by a pair of pre-pressing rollers 3 below it to become a glass ribbon 4 with a thickness slightly larger than the thickness of the final thin plate glass. Manually ( Or use a mechanical method to guide it to the right in the figure, so that when it goes down to the forming surface block placed on the small platform where the lower crawler protrudes from the end of the upper crawler, the forming surface that moves to the right The effect of block surface friction moves along with it to the middle seam between the forming surface blocks 12 placed up and down on two crawlers (flat track shoes). When the end of the glass liquid belt 4 enters the middle seam, under the action of the crawler support compactor 7, the forming surface block 12 between the surfaces 5 of the two crawler belts (flat track shoes) immediately squeezes the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com