Arc-shaped plate and machining process thereof

A processing technology and plate technology, which is applied in the field of curved plate and its processing technology, can solve the problems of transparency, scratch resistance and hardness, and the three-dimensional effect of the pattern is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

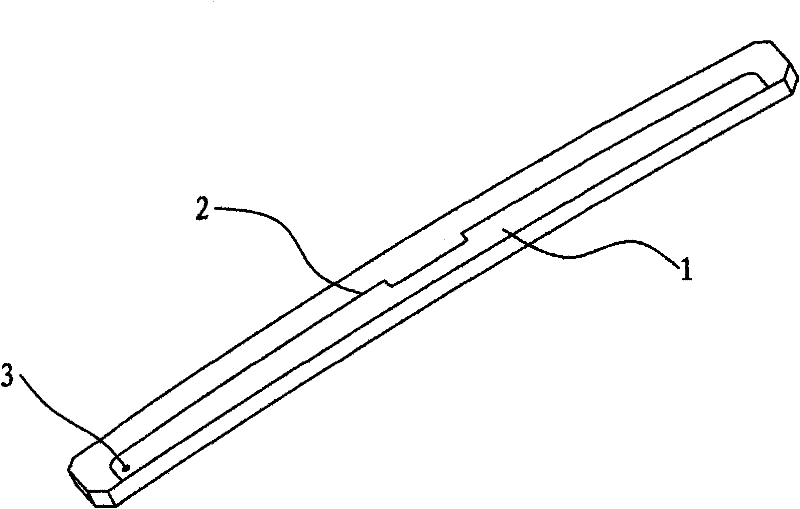

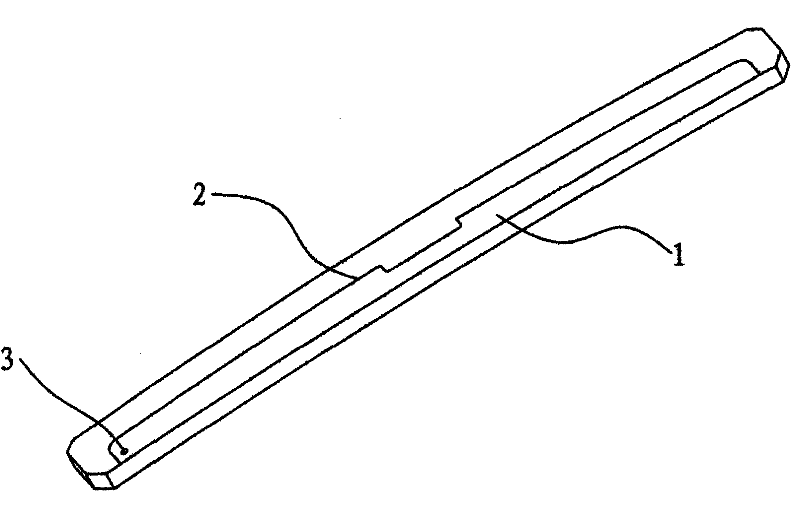

[0013] See figure 1 As shown: the present invention adopts the following technical scheme: it includes an arc-shaped plate 1, which is a plastic plate with a curvature, and its front or back is provided with a surface treatment pattern 2, and the arc-shaped plate 1 can be provided with holes 3 as required and other shapes.

[0014] The curved plate 1 is any one of transparent plate and opaque plate.

[0015] A method for manufacturing a curved plate, comprising the following steps:

[0016] (1) Firstly, the plate is cut, and the surface treatment is carried out on the front or the back, and the surface treatment pattern 2 is on the front or the back.

[0017] (2), put into the mold and fix, heat and bake for 60-180 minutes, and then cool;

[0018] (3) According to the required shape, cut and shape;

[0019] (4) Corner treatment and shaping.

[0020] The characteristics of the present invention: do not destroy the original characteristics of the plate, and retain its advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com