Lighting system for automatic optic inspection and combination of lighting system and image system

An automatic optical detection and lighting system technology, applied in the field of lighting system and its combination with imaging system, can solve problems such as large space optical path, achieve the best imaging quality and reduce the space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

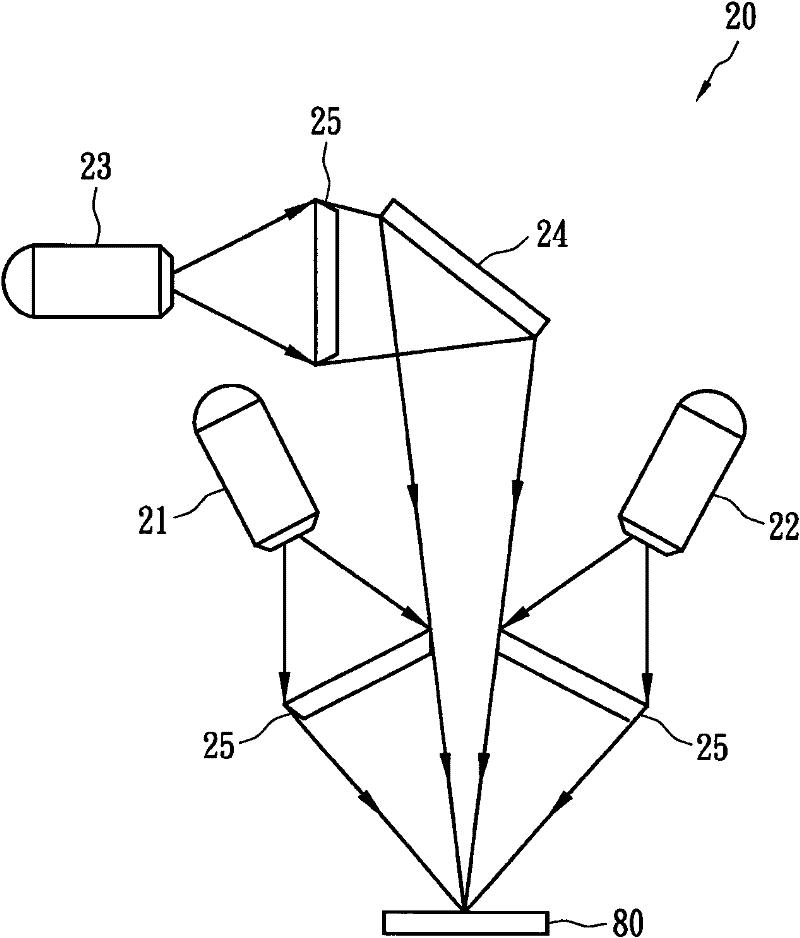

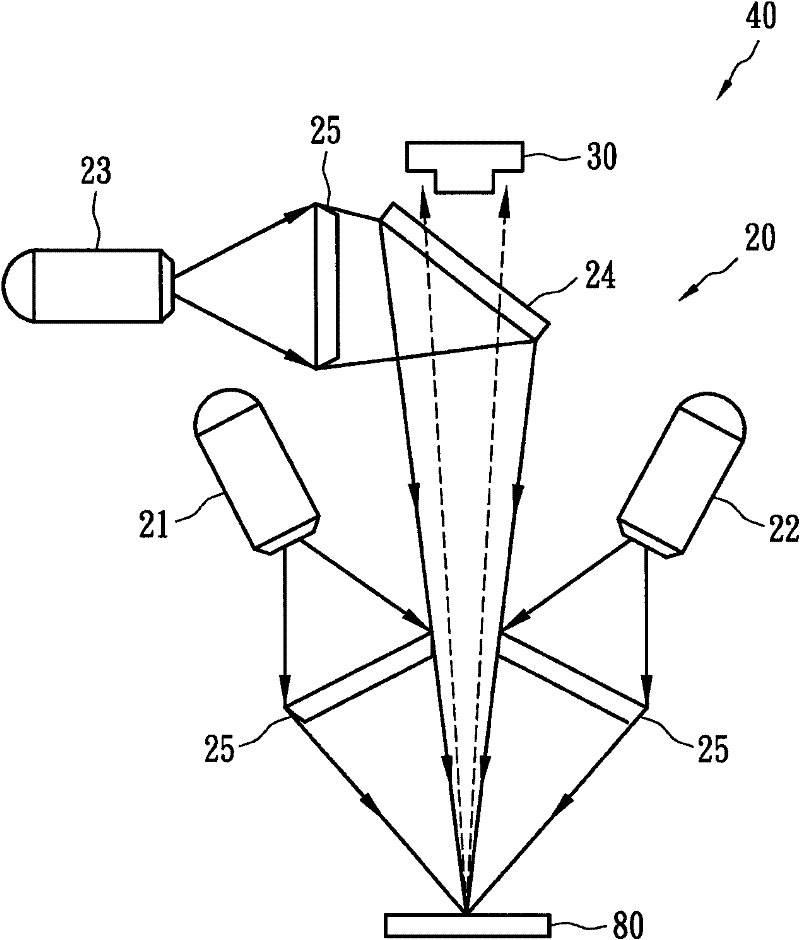

[0037] figure 2 It is a schematic diagram of an illumination system 20 for automatic optical inspection according to an embodiment of the present invention, illuminating an object 80 to be inspected, which includes a first light source 21, a second light source 22, a third light source 23, a The first optical element 24 and at least three second optical elements 25 . Each of the second optical elements 25 is respectively arranged on the light output ends of the first light source 21, the second light source 22 and the third light source 23, and can directly or indirectly concentrate the light output by each light source on the object to be detected. An axis on the surface of object 80 . The light output ends of the first light source 21 and the second light source 22 are symmetrically directed to the surface of the object, and the light sources 21-23 are an LED linear light source or a fiber optic linear light source. In addition, the first optical element 24 is roughly ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com