Large-aperture off-axis reflection type quantitative consistency test and calibration device for multiple optical axes

An off-axis reflection and calibration device technology, which is used in measurement devices, optical instrument testing, and optical performance testing. High precision and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

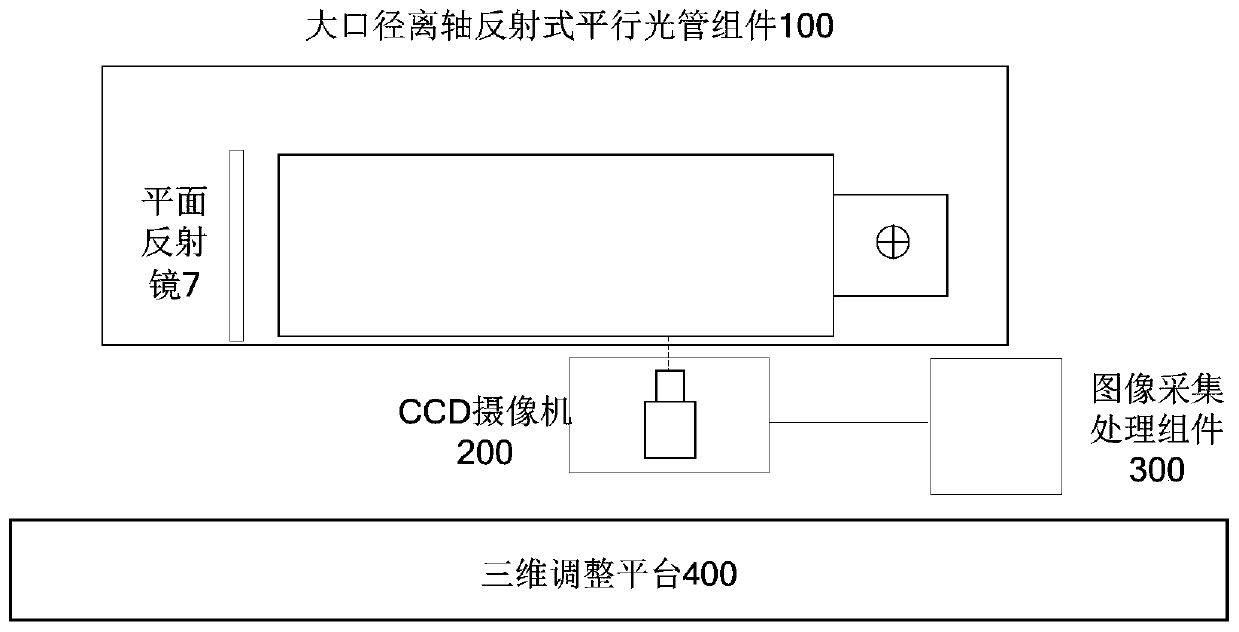

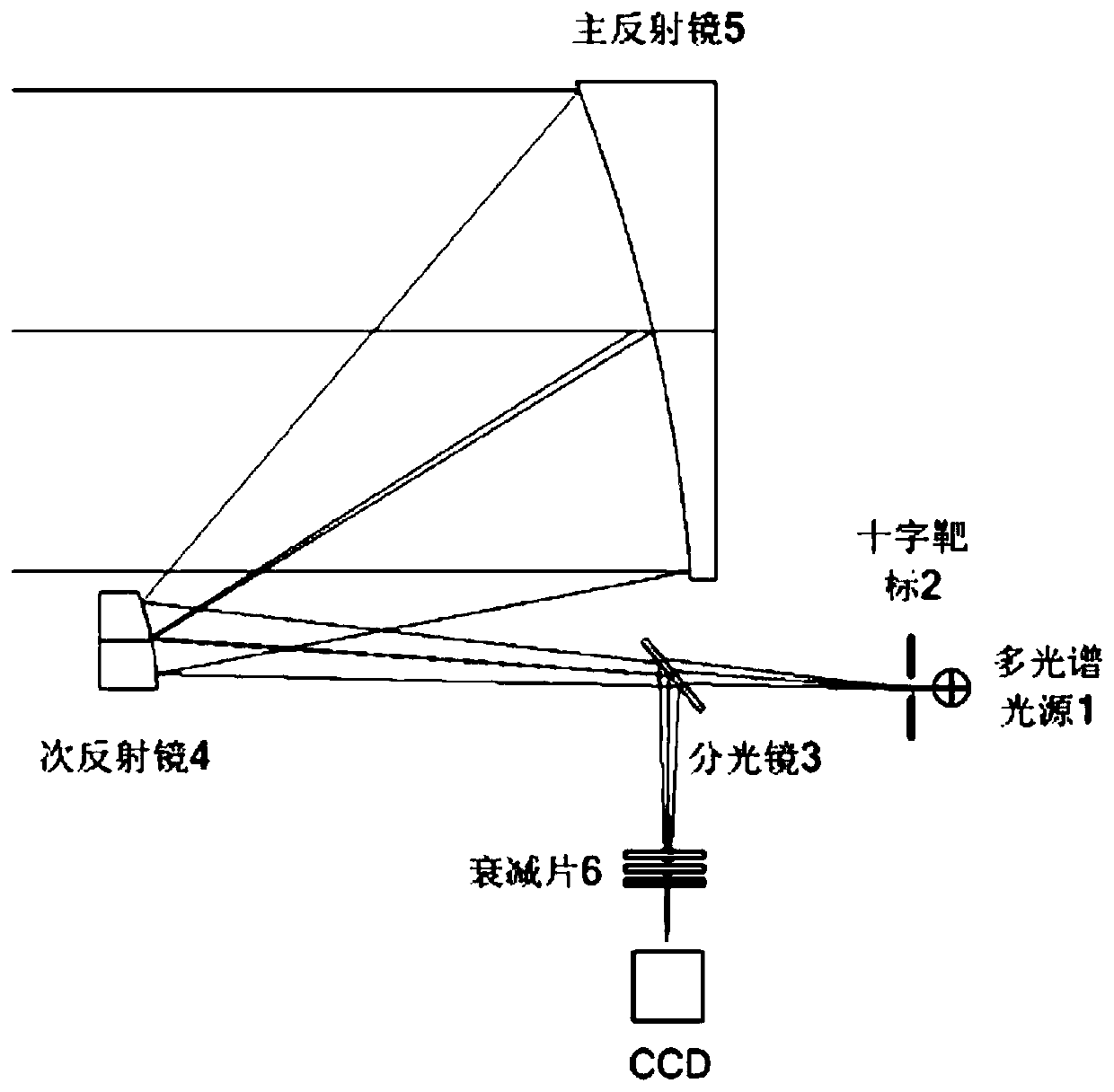

[0029] Such as figure 1 and figure 2 As shown, a large-diameter off-axis reflective multi-optical axis consistency quantitative test and calibration device includes a large-diameter off-axis reflective collimator assembly 100, a CCD camera 200, an image acquisition and processing assembly 300, and a three-dimensional adjustment platform 400;

[0030] The CCD camera 200 is arranged on the focal plane of the branch of the CCD camera formed by the beam splitter in the large-diameter off-axis reflective collimator assembly 100 , and the center of the sensitive surface of the CCD camera 200 is aligned with the main optical axis of the branch of the CCD camera. The image acquisition and processing component 300 is connected with the CCD camera ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com