Digital signal processor (DSP)-based rotating machine vibration detection and protection system

A vibration detection and protection system technology, applied in the field of measuring instruments, can solve the problems of increasing system complexity and cost, signal processing powerlessness, and limited computing power of single-chip microcomputer, etc., to achieve powerful signal processing capabilities, reduce computing load, and facilitate expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

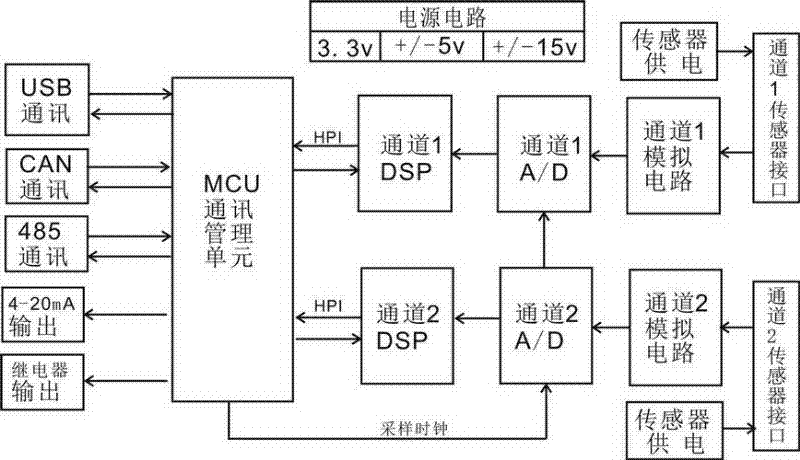

[0022] Such as figure 1 The DSP-based rotating machinery vibration detection and protection system shown mainly includes a power supply module, a sensor power supply module, a sensor signal acquisition and conditioning module, and a microprocessor MCU module; the power supply module is used to provide +3.3V, +5V, -5V , +15V, -15V voltage level system power supplies power to the sensor, MCU, etc.; the sensor power supply module is used to provide different power supply modes for different types of sensors.

[0023] Sensor signal acquisition and conditioning module, including channel 1 sensor interface, channel 1 analog circuit, channel 1 analog-to-digital conversion circuit, channel 2 sensor interface, channel 2 analog circuit, channel 2 analog-to-digital conversion circuit; the sensor signal acquisition and conditioning modules pass through channel 1 The sensor interface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com