Bonding apparatus and bonding method

A bonding device and a technology for bonding parts, which are applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of large wiring impedance, decreased productivity of wafer bonding processing, and a large amount of time to achieve high-efficiency bonding, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

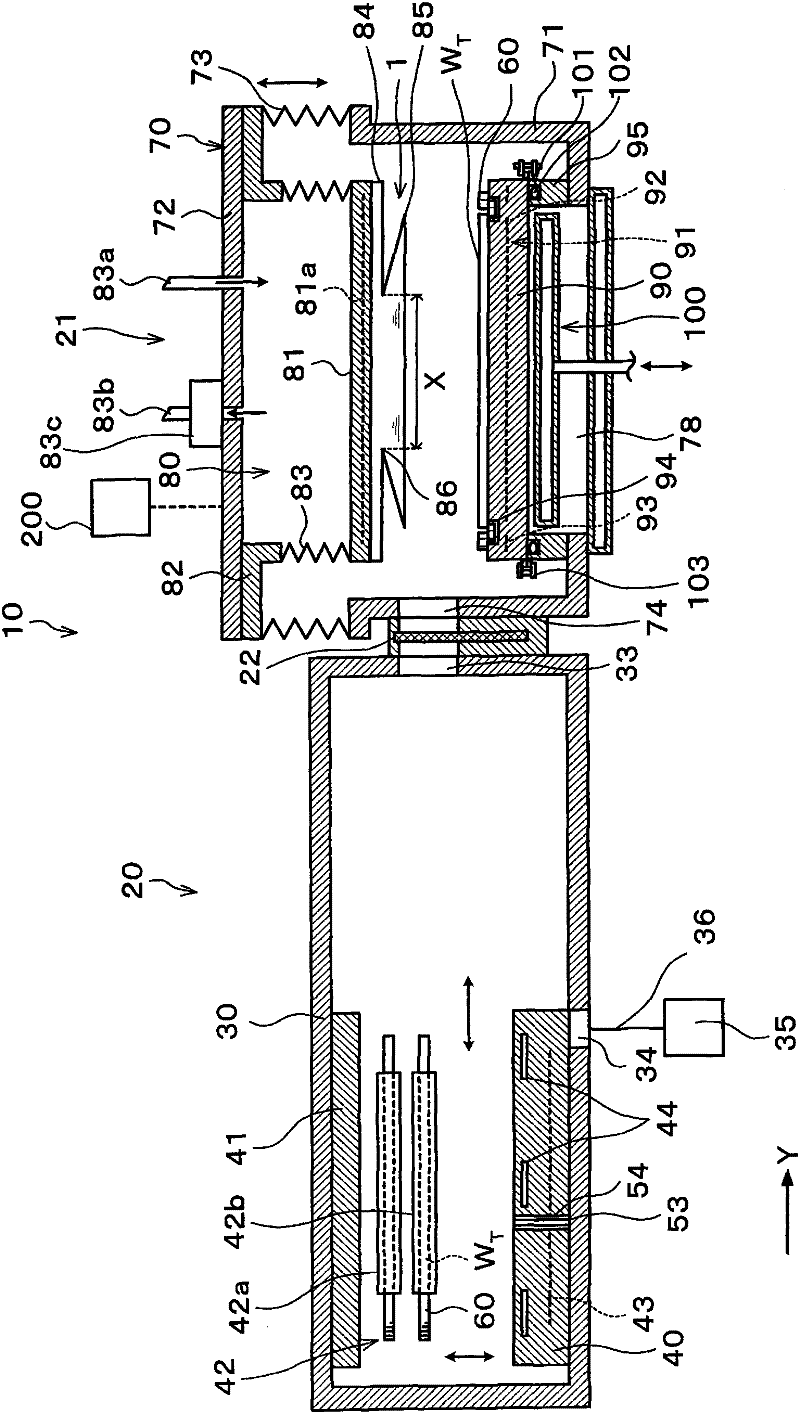

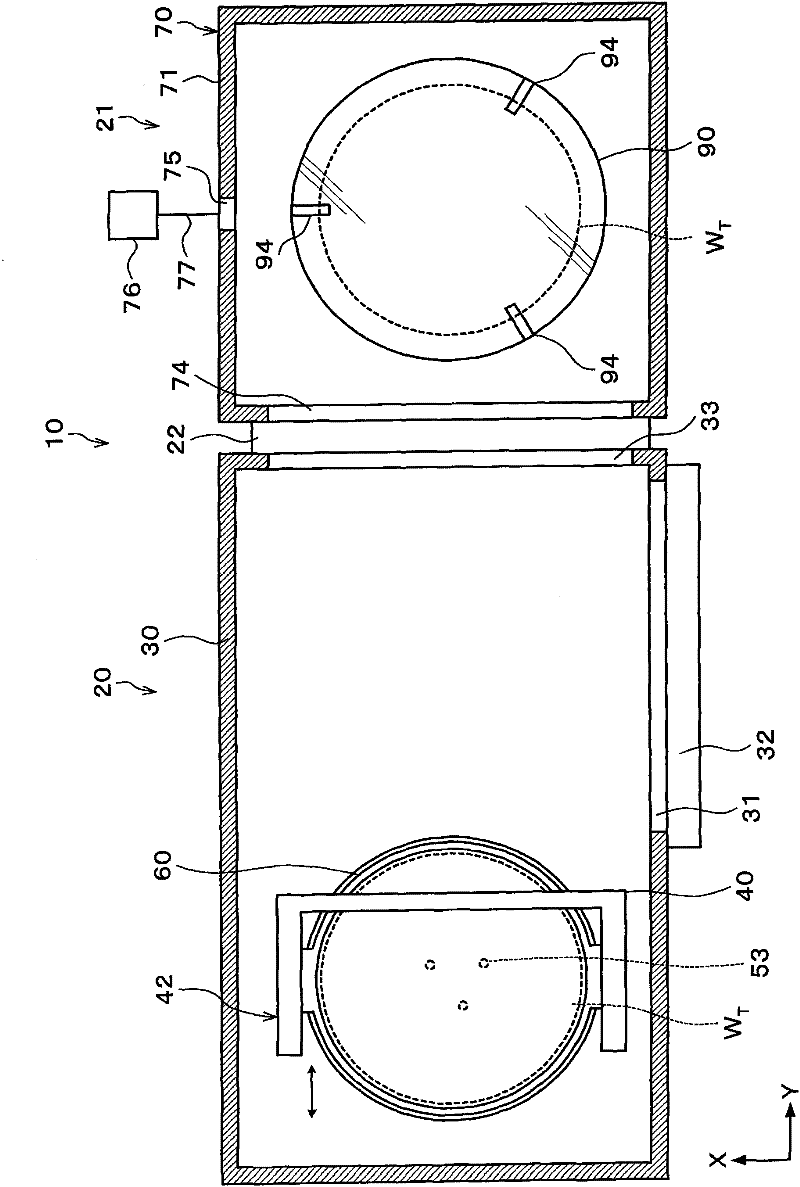

[0040] Embodiments of the present invention will be described below. figure 1 It is a longitudinal sectional view showing a schematic configuration of a joining device 10 having a pressing adapter 1 . figure 2 It is a cross-sectional view showing a schematic configuration of the joining device 10 having the pressing attachment 1 .

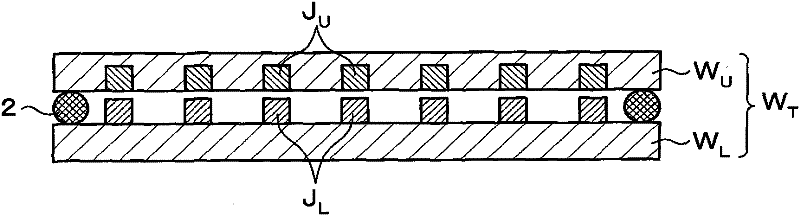

[0041] In the joining device 10, such as image 3 As shown, for example, two wafers W as substrates U , W L join together. Hereinafter, the wafer disposed on the upper side may be referred to as "upper wafer W U ", the wafer configured on the lower side is called "lower wafer W L ". Each wafer W U , W L Joints J each having a plurality of metals U 、J L . And, make each joint J U 、J L abutment so that the wafer W U , W L stacked to form a stacked wafer W as a stacked substrate T , and then the wafer W U , W L join each other. In addition, during the wafer W U , W L state before engagement of each other, such as image 3 shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com