Transistor and method of making the same

A manufacturing method and transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve excellent carrier mobility and broaden the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

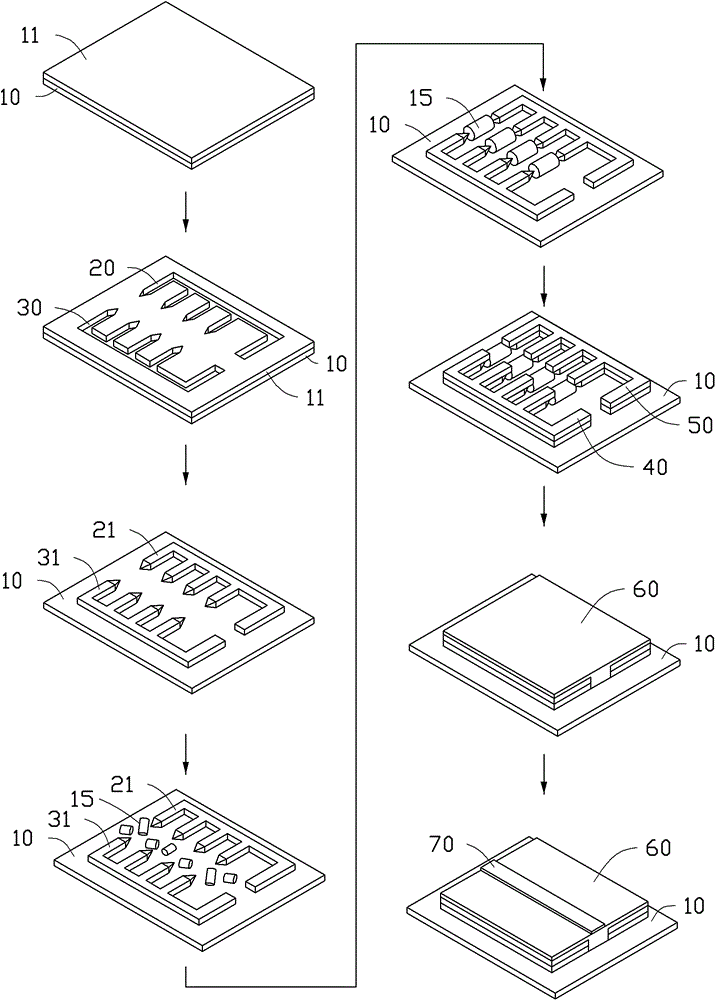

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

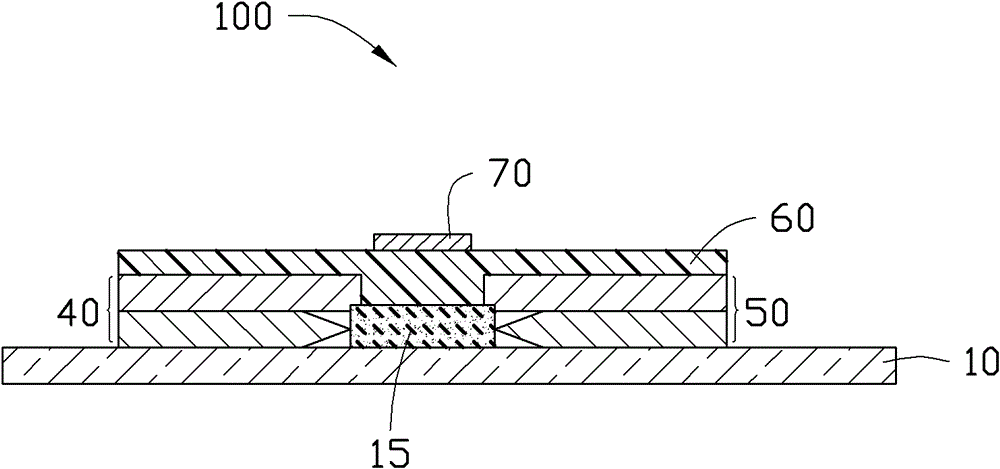

[0024] See figure 1 , the transistor 100 provided by the embodiment of the present invention includes a substrate 10 , a nanowire 15 , a source 40 , a drain 50 , an insulating layer 60 and a gate 70 .

[0025] The source electrode 40 and the drain electrode 50 are attached on the substrate 10 opposite to each other at intervals. In this embodiment, the source electrode 40 and the drain electrode 50 are formed by stacking two layers of conductive films, and are close to the substrate. The opposite ends of the two conductive film layers of 10 are all pointed designs.

[0026] It can be understood that the source 40 and the drain 50 can also be a single-layer structure.

[0027] The nanowire 15 overlaps between the tips of the source 40 and the drain 50 to serve as an electron and hole transmission channel between the source 40 and the drain 50 .

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com