Method for rapidly measuring weight of flotation foam product

A technology of weight and product, applied in the field of flotation test, can solve the problems of wasting time and resources, increasing cost, unable to meet instant adjustment conditions, etc., and achieving the effect of convenient speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

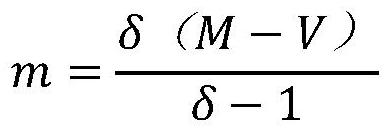

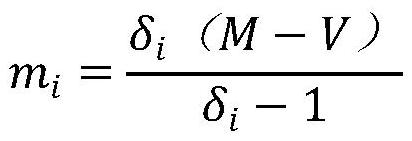

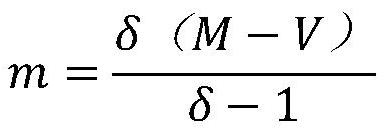

Method used

Image

Examples

example 1

[0039] The measurement of a copper mine distribution foam product is 4.5% compared to the actual weight.

example 2

[0041] A flotation test foam for a rhodium mine is measured, and the error is 3.2% compared to the actual weight.

[0042] The present invention is fast, which is fast, equivalent to immediate measurement, and does not change the morphology and properties of the slurry, and improve the test efficiency and improve the effect.

[0043] 1) When the foam product is the final product of the trial, this method is compared with the traditional solid-liquid separation-dry-weighing, the convenient speed is fast (drying usually takes longer). This instant fast measurement is conducive to flexible control of flotation conditions. It is not enough, continue to blow, the foam is insufficient, and the agent is added; the amount is enough, the flotation is stopped;

[0044] 2) When the foam product is not a final product, this method does not change the product morphology and nature, that is, master the amount of foam products, and does not affect the subsequent selection; for closed-circuit tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com