Tufted carpet for automotive applications

A technology for tufted carpets and carpets, applied in the field of tufted carpets, can solve problems such as stress whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention relates generally to vehicle floor systems, deck side trim, optional mats or other interior trim pieces and more particularly to tufted PP carpet or tufted PET carpet and methods of production thereof.

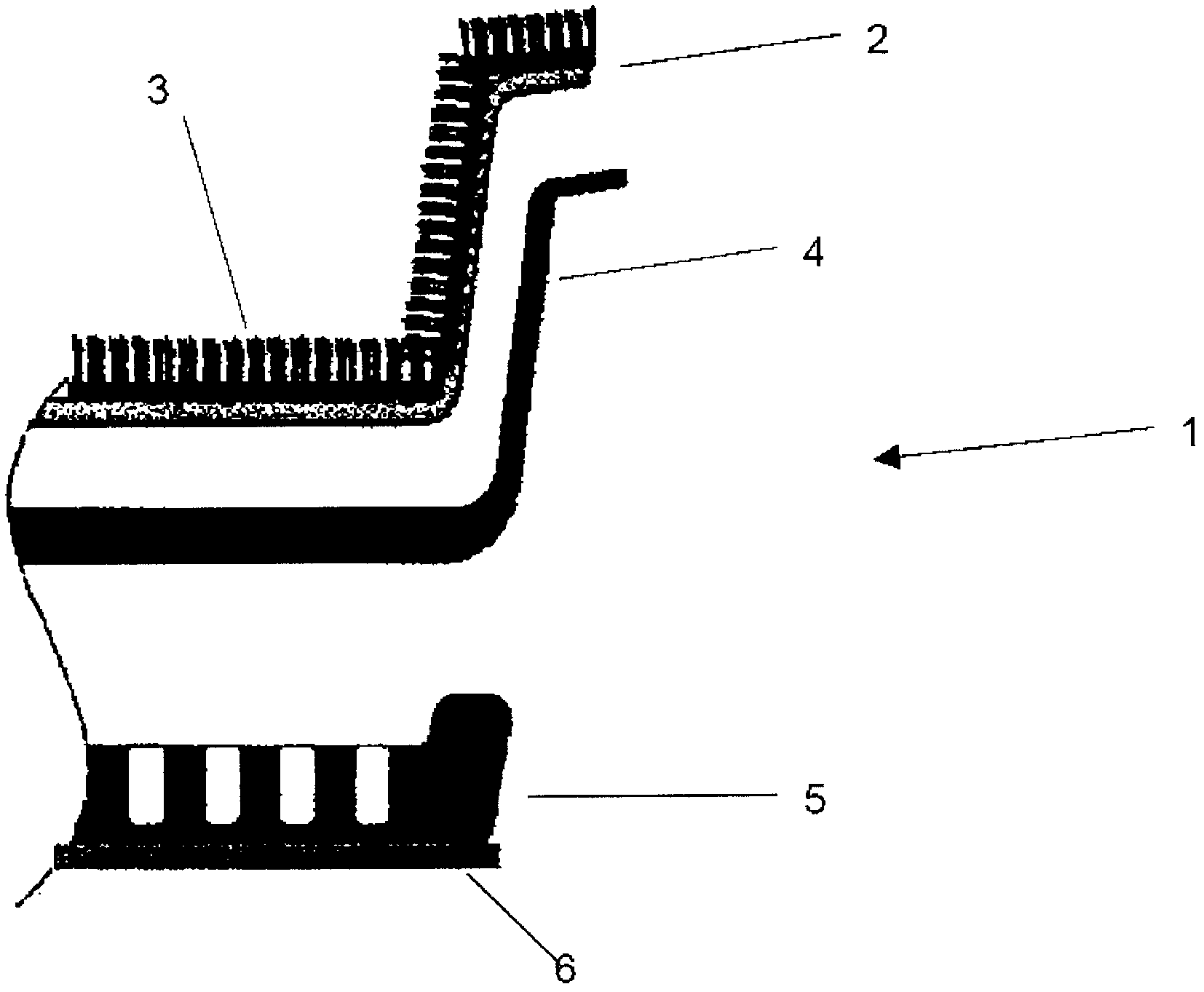

[0030] refer to figure 1 , shows an embodiment of a floor system 1 substantially according to the known prior art. The vehicle floor system 1 comprises three main components, the first being a carpet 2 with a decorative fiber top layer 3, the second being an underlayment 4 and the third being an acoustic and The vibration damping layer 5 of the vibration damping layer. The damping layer 5 is the layer which is in contact with the body shell, the body 6 of the vehicle, which damping layer is generally based on foam and fiber materials.

[0031] The substrate 4 may be an absorber or a barrier layer and may be based on a combination of fibers and foams to form a controlled porous substrate.

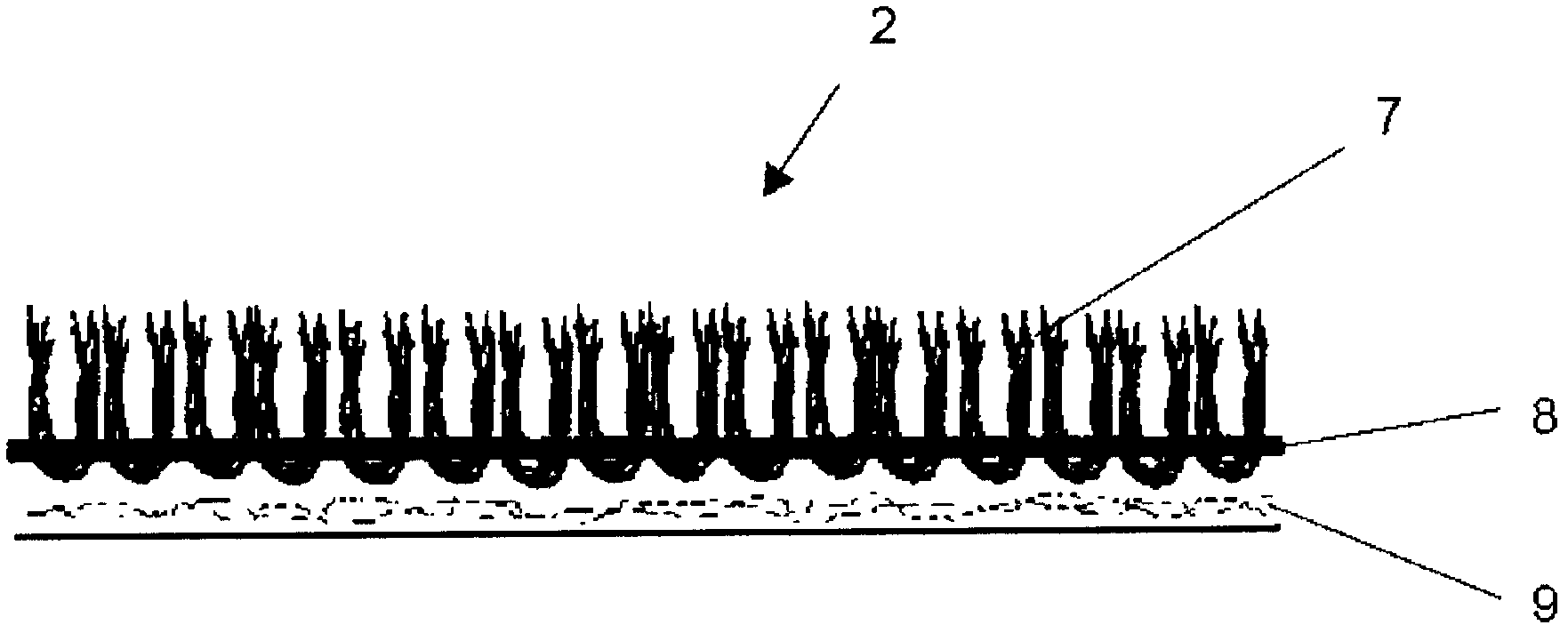

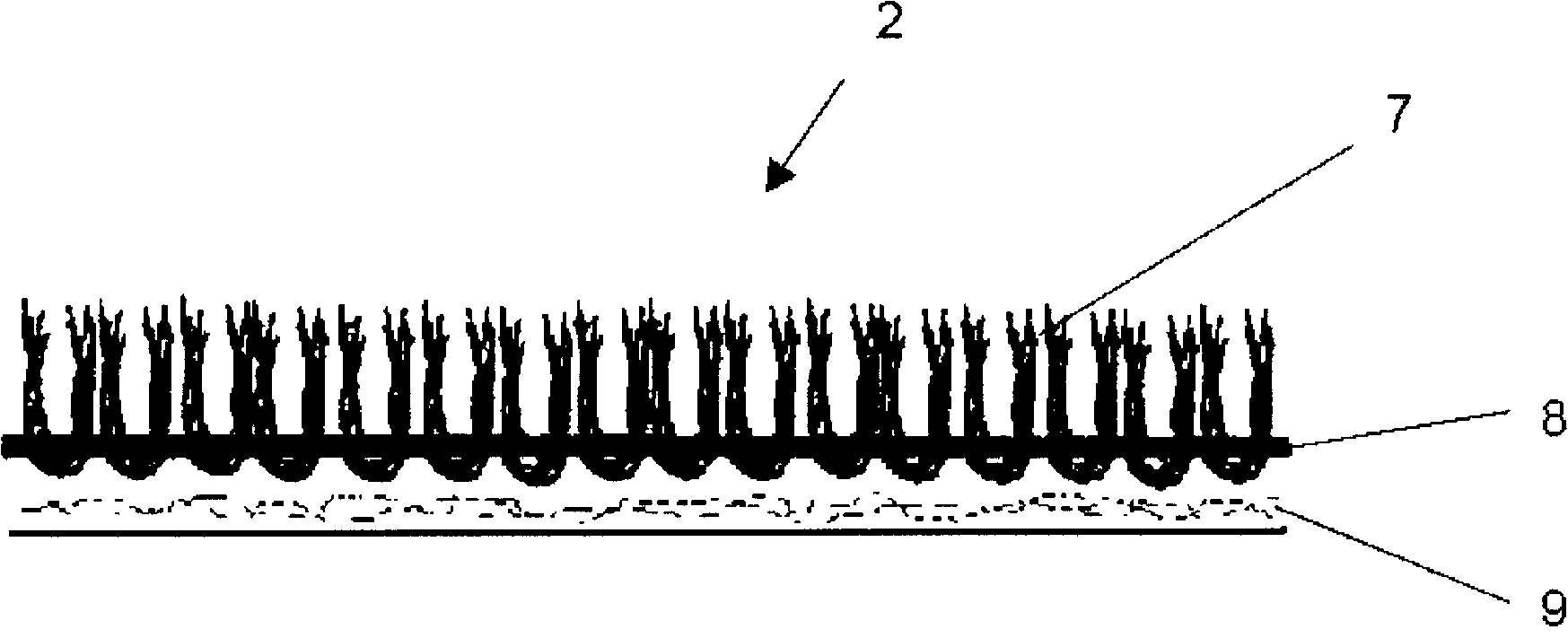

[0032] The carpet 2 is formed of two layers, a pile laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com