Lower-thread tension control device for sewing machine, and sewing machine

A technology for tension control and sewing machines, which is applied to the loop mechanism of sewing machines, bobbin winding in sewing machines, and sewing machine components. The effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

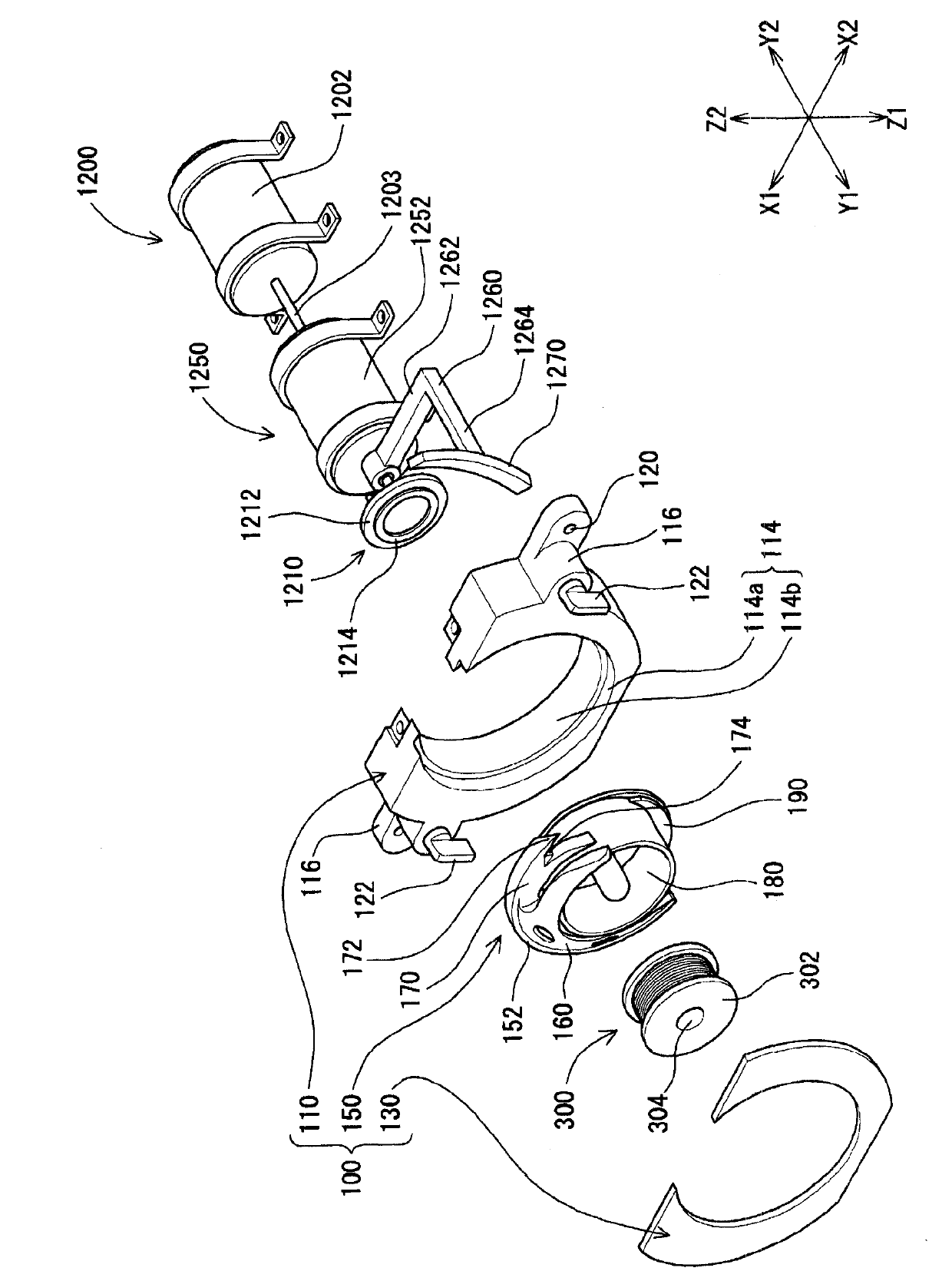

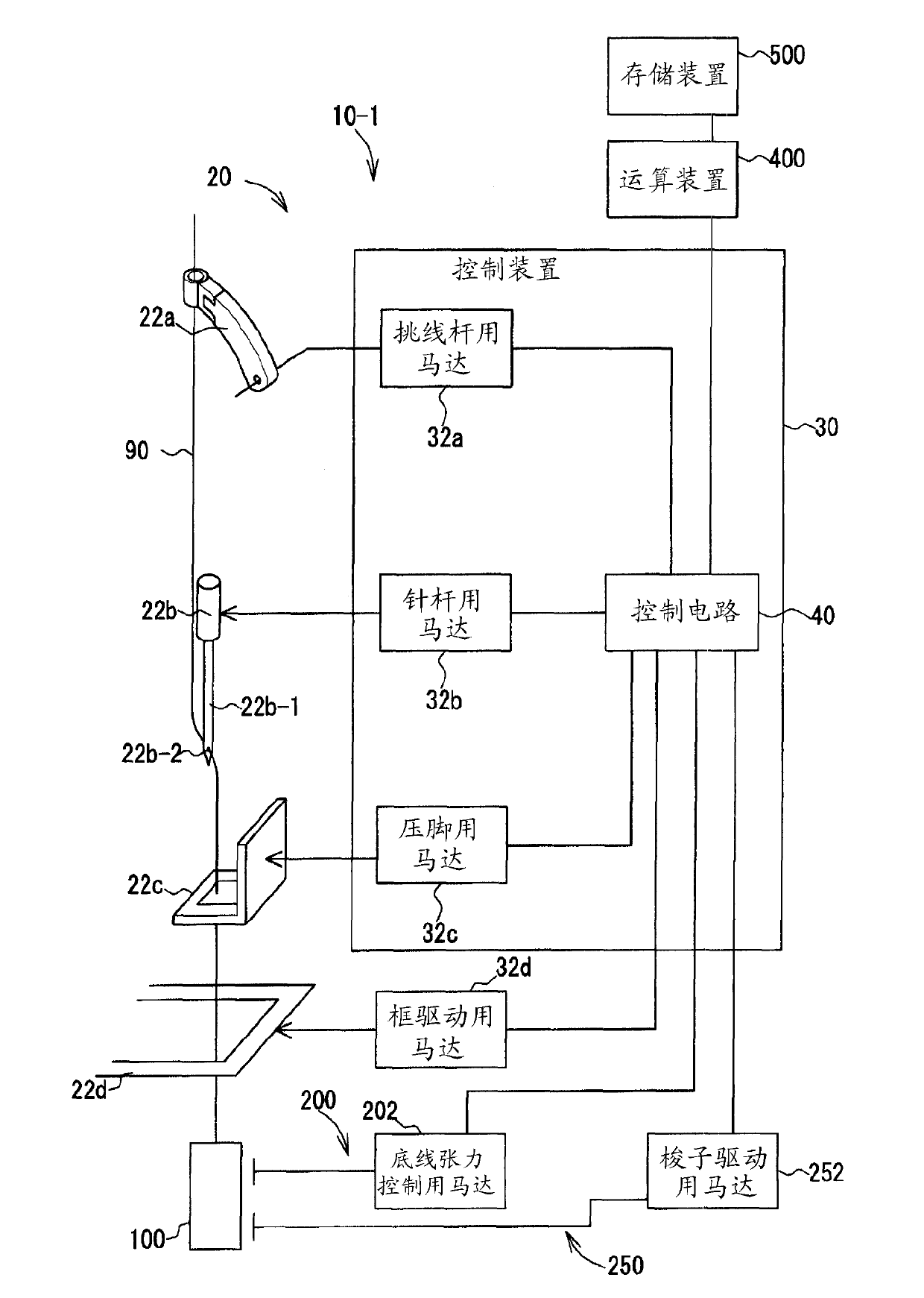

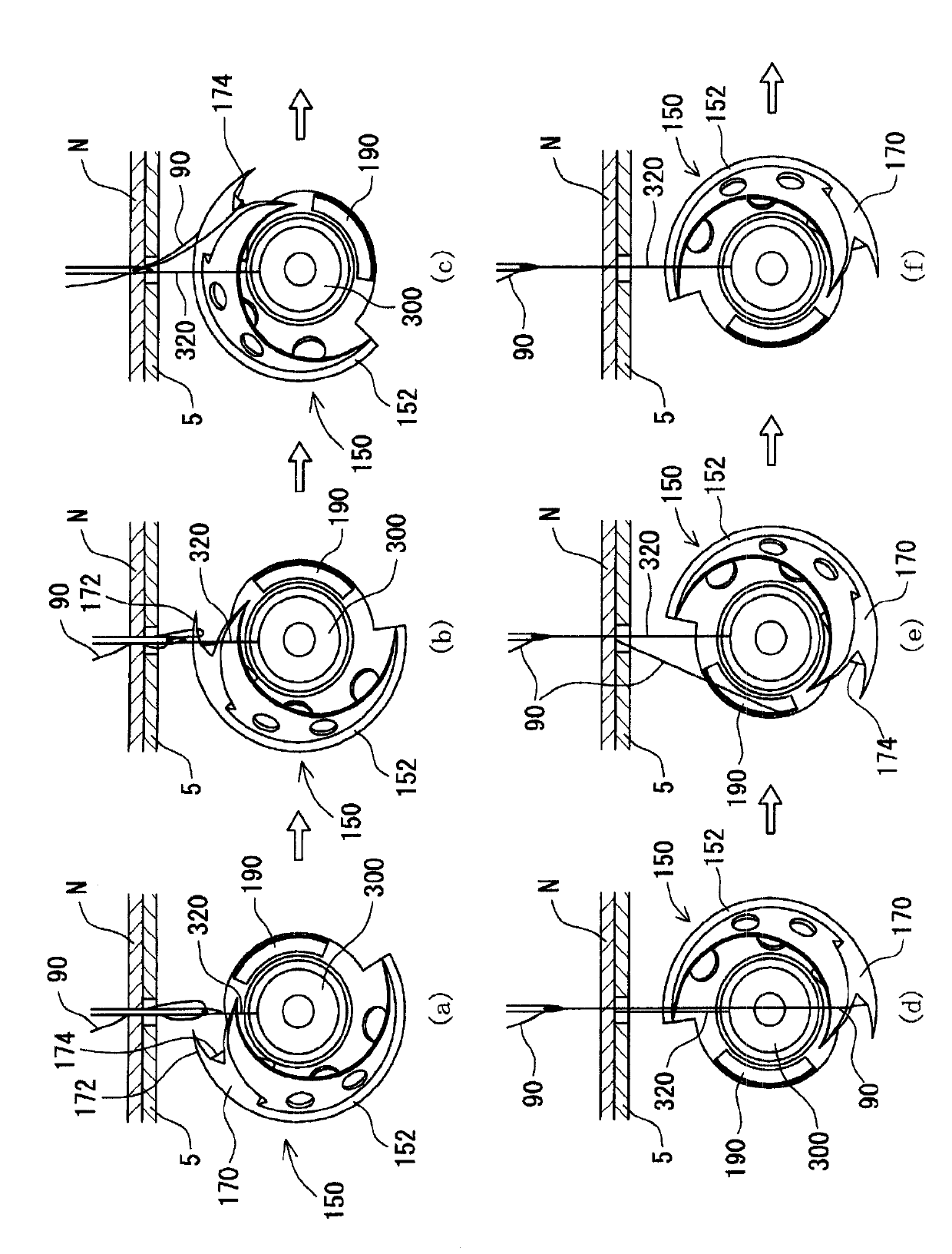

[0080] As an embroidery sewing machine 1 based on the sewing machine of the present invention, such as Figure 1 to Figure 13 As shown in the structure, it has: a sewing machine table 3, embroidery heads 10-1 to 10-n, a sewing frame (which can be used as a holding frame or an embroidery frame) 22d, a frame driving motor 32d, a shuttle 100, and a bobbin thread tension control mechanism 200, a shuttle driving part 250, a bobbin 300, an arithmetic device 400, and a storage device 500.

[0081] Here, the sewing machine table 3 is substantially flat, such as Figure 4 As shown in FIG. 1 , there is a plate-shaped table main body 4 and a needle plate 5 provided in an opening formed in the table main body 4 .

[0082] Furthermore, the embroidery heads 10-1 to 10-n are provided above the sewing machine table 3, and each of the embroidery heads 10-1 to 10-n is arranged in a substantially straight line at predetermined intervals. That is, a frame (not shown) is erected from the upper s...

Embodiment 2

[0159] The embroidery sewing machine in the second embodiment has substantially the same structure as that in the first embodiment, but is different in that the middle shuttle has a full rotation structure. That is, the middle shuttle in the above-mentioned embodiment 1 is a semi-rotary type, while the middle shuttle in the embodiment 2 is a full-rotation type. Compared with the embodiment 1, the structure of the bobbin thread tension control mechanism part and the shuttle driving part is different.

[0160] The structure of the shuttle 100 in the present embodiment, the bobbin thread tension control mechanism part 1200, and the shuttle driving part 1250 is as follows: Figure 17 As shown, the structure of the shuttle 100 is the same as that of the shuttle 100 in the first embodiment.

[0161] The bobbin thread tension control mechanism unit 1200 includes a bobbin thread tension control motor 1202 and a rotary disk 1210 attached to a rotary shaft 1203 of the bobbin thread tens...

Embodiment 3

[0187] Hereinafter, based on the sewing machine for embroidery of Embodiment 3, use Figure 20 ~ Figure 28 Be explained. The embroidery sewing machine in the third embodiment has substantially the same structure as that in the first embodiment, but the structure of the inner shuttle 150 and the rotating disk 210 in the bobbin thread tension control mechanism part 200 is different.

[0188] That is, if Figure 20 ~ Figure 25 As shown, the back part 161 of the middle shuttle body part 160 in the middle shuttle 150 is composed of a back body part 162 and a back side tapered part 164, but the structure of the back body part 162 is different from that of Embodiment 1.

[0189] That is, the rear main body portion 162 such as Figure 20 ~ Figure 22 , Figure 24 As shown, there is an annular plate-like portion (back plate-like portion) 162a, and a concave portion (back-side concave portion) 162b formed in the center of the flat plate-shaped portion 162a.

[0190] That is, the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com