Combined type degassing technology for vacuum oil filter

A vacuum oil filter, combined technology, applied in the directions of liquid degassing, chemical instruments and methods, separation methods, etc., can solve the problems of general degassing effect and underutilization, etc., so as to facilitate sufficient contact with vacuum, reduce Volume, the effect of improving degassing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

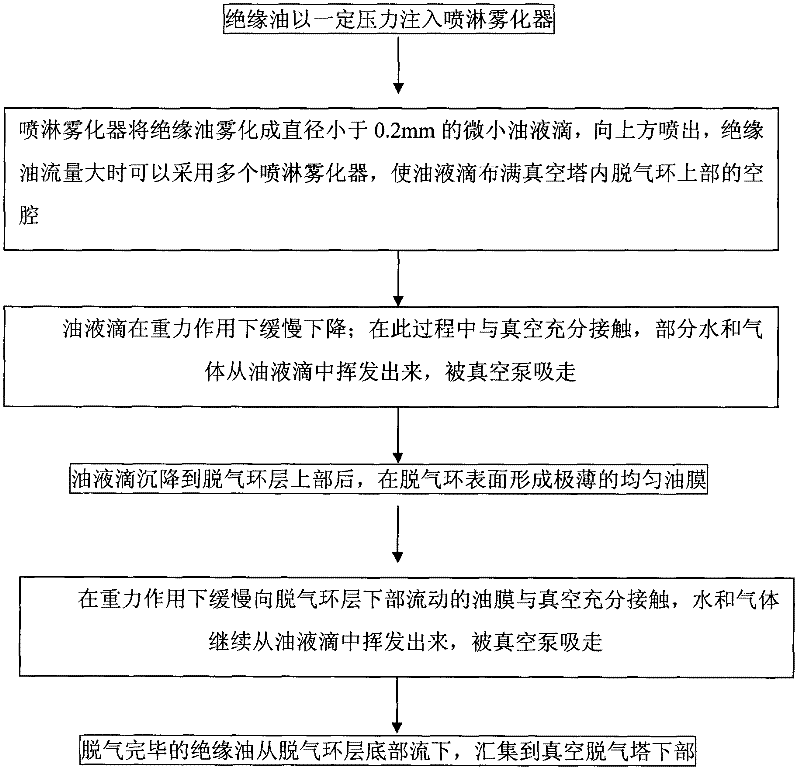

Method used

Image

Examples

Embodiment 1

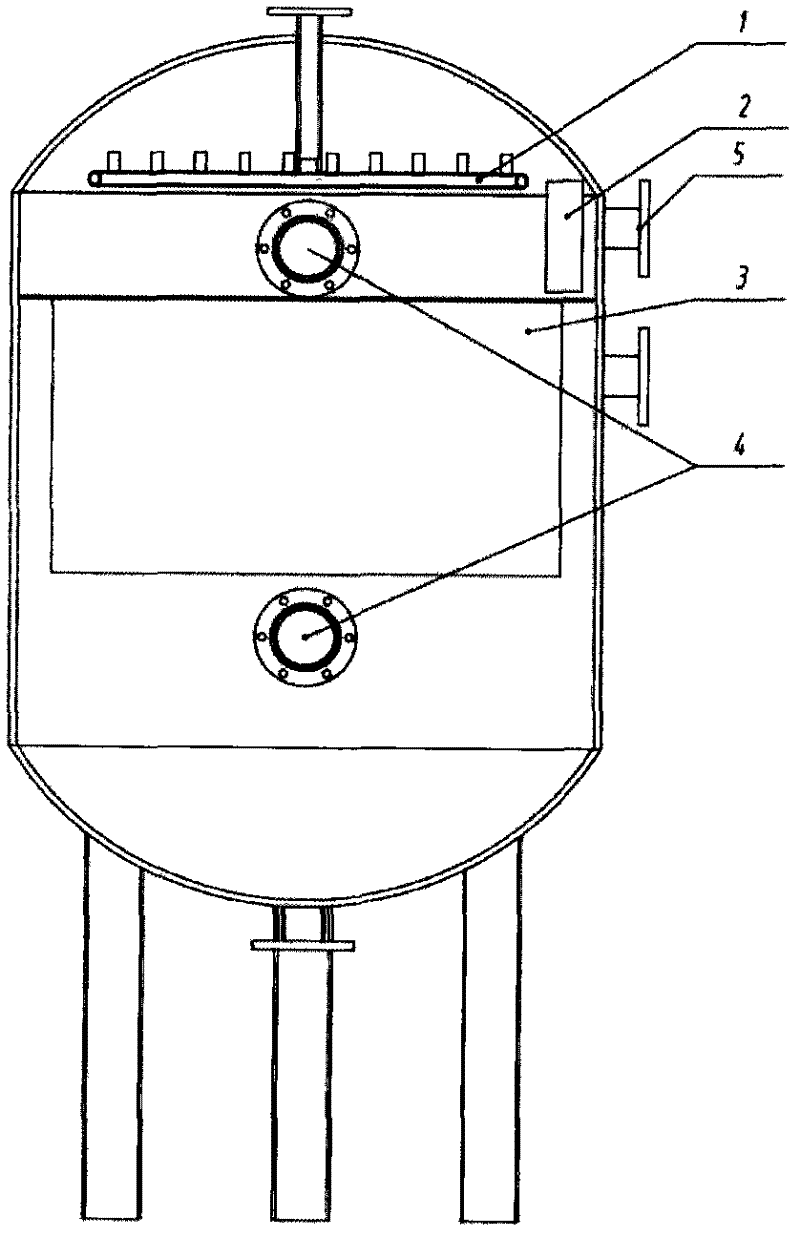

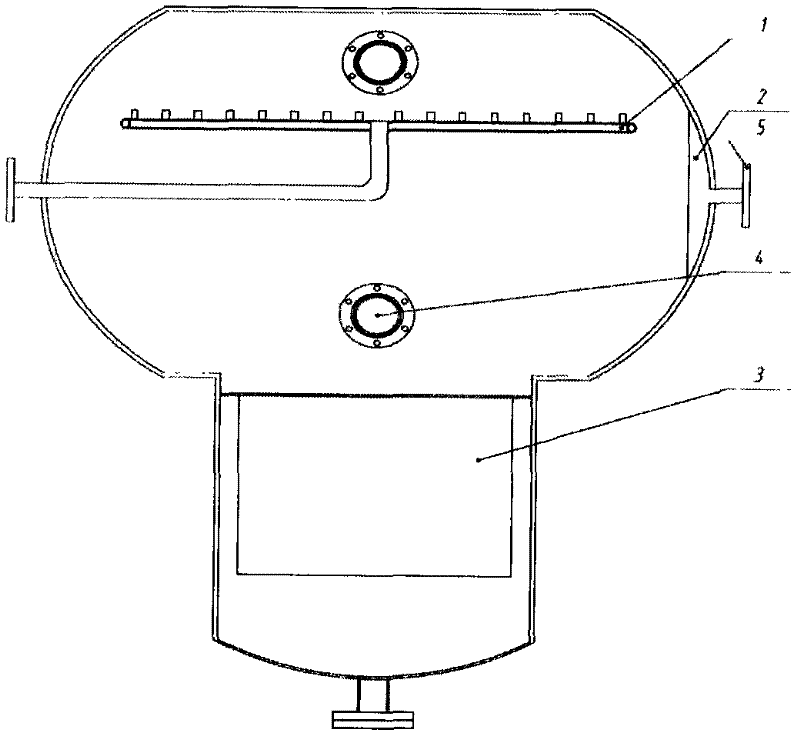

[0032] exist figure 2 Among them, the vacuum degassing tower has a cylindrical structure, and the insulating oil is injected at a pressure of 0.2Mpa and atomized by the spray atomizer (1) to obtain tiny oil droplets with a diameter of less than 0.2mm. Multiple spray atomizers (1) Arranged in the upper part of the vacuum degassing tower in a ring shape, so as to make the tiny oil droplets fill the upper part of the vacuum degassing tower. The atomized oil droplets fall evenly under the action of gravity. After falling to the degassing ring layer (3), an oil film is formed on the surface of the degassing ring to realize the evaporation of water and gas in the oil. The evaporated water and gas are pumped out of the vacuum degassing tower by the vacuum system, and in the vacuum degassing tower There is an oil mist baffle (2) at the vacuum suction port to ensure that the atomized oil droplets gather and fall without being sucked out by the vacuum system.

Embodiment 2

[0034] exist figure 2 Among them, the vacuum degassing tower has a T-shaped structure, and the insulating oil is injected at a pressure of 0.2Mpa and atomized by the spray atomizer (1) to obtain tiny oil droplets with a diameter of less than 0.2mm. Multiple spray atomizers (1) Arranged in a straight line in the upper cavity of the T-shaped vacuum degassing tower, so that the tiny oil droplets fill the upper cavity of the vacuum degassing tower. The atomized oil droplets fall evenly under the action of gravity. Then converge to the degassing ring layer (3) in the lower cavity, and form an oil film on the surface of the degassing ring to realize the evaporation of water and gas in the oil. The evaporated water and gas are pumped out of the vacuum degassing tower by the vacuum system, There is an oil mist baffle (2) at the vacuum suction port of the vacuum degassing tower to ensure that the atomized oil droplets gather and fall down without being pumped out by the vacuum system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com