Novel pressure device for finely turned bright aluminum alloy wheel

A pressurizing device, aluminum alloy technology, applied in the field of automobile aluminum alloy wheel casting, can solve problems such as oxide slag inclusion, and achieve the effects of low purification cost, high cleanliness, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] specific implementation

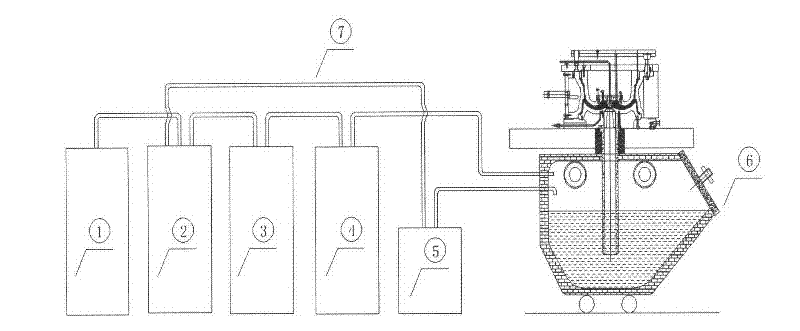

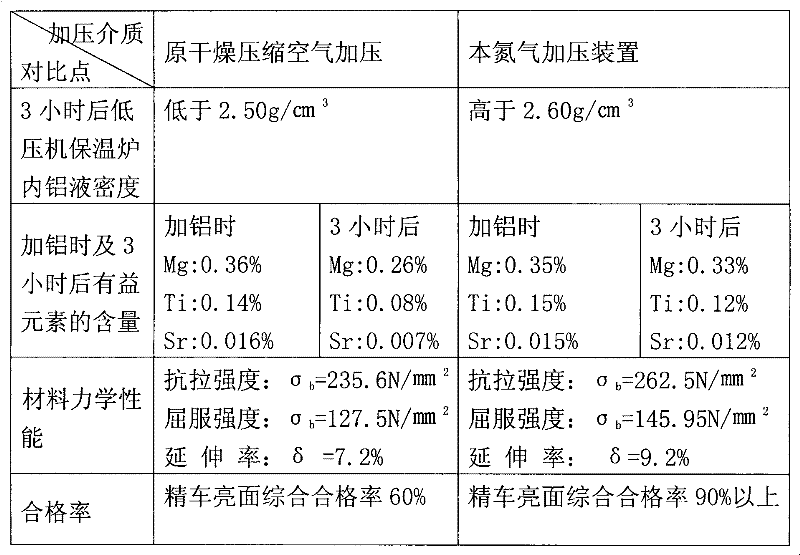

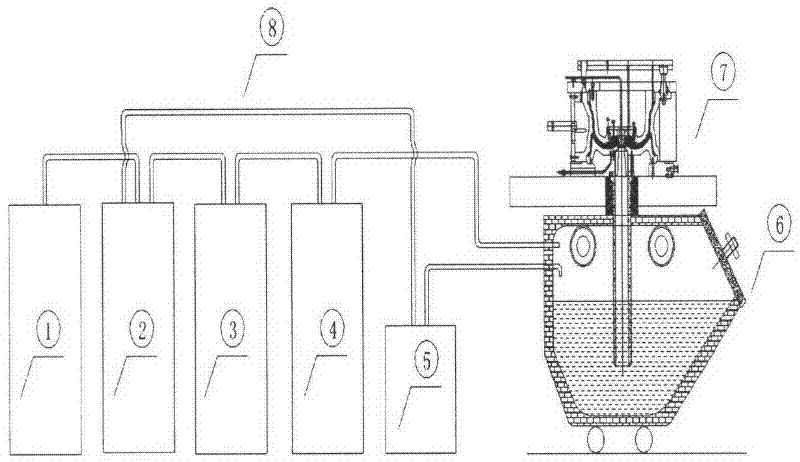

[0008] Such as figure 1 As shown, a new pressurization device for bright aluminum alloy wheels of fine cars, including nitrogen generator 1, nitrogen dryer 2, gas storage tank 3, low pressure casting machine system control cabinet 4, pressure relief nitrogen recovery tank 5, low pressure Machine aluminum liquid holding furnace 6, gas conduit 7. The nitrogen produced by the nitrogen generator 1 leads to the nitrogen dryer 2 through the conduit 7, the nitrogen purity is greater than or equal to 99.99%, and the nitrogen dew point is less than or equal to -45; the dried and purified nitrogen leads to the gas storage tank 3 through the conduit 7, and the gas storage tank The nitrogen gas in 3 leads to the control cabinet 4 of the low-pressure casting machine system through the conduit, and the nitrogen gas in the control cabinet 4 of the low-pressure casting machine system leads to the holding furnace 6 of the low-pressure machine for pressurizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com