Automatic centering compaction clamp for Danfoss cylinder body

An automatic centering and cylinder technology, which is used in clamping, positioning devices, manufacturing tools, etc., can solve the problems of long clamping and pressing time, large operator's physical expenditure, complicated positioning and pressing, etc. To achieve the effect of short clamping time, reducing physical consumption, reducing clamping and pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

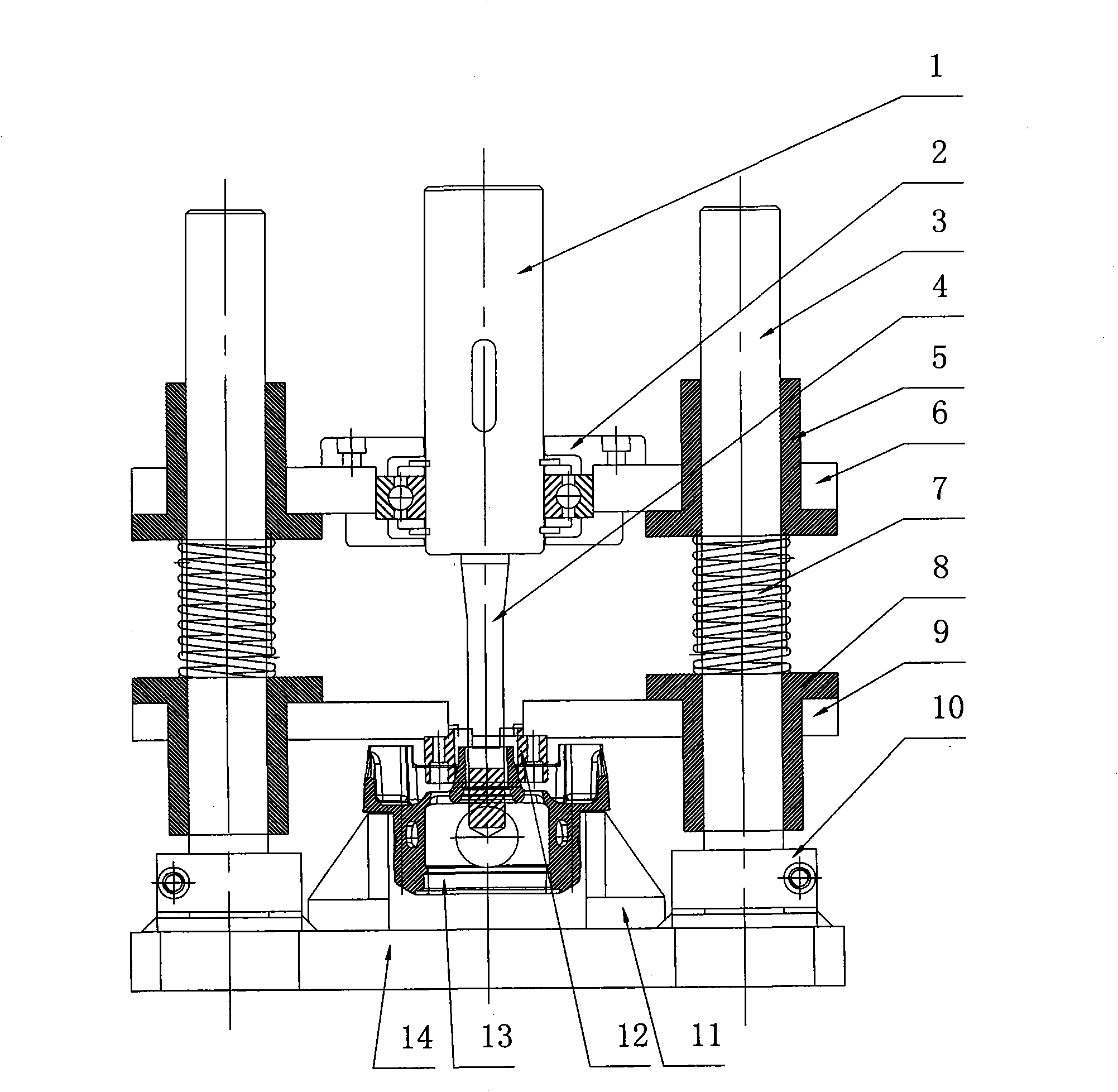

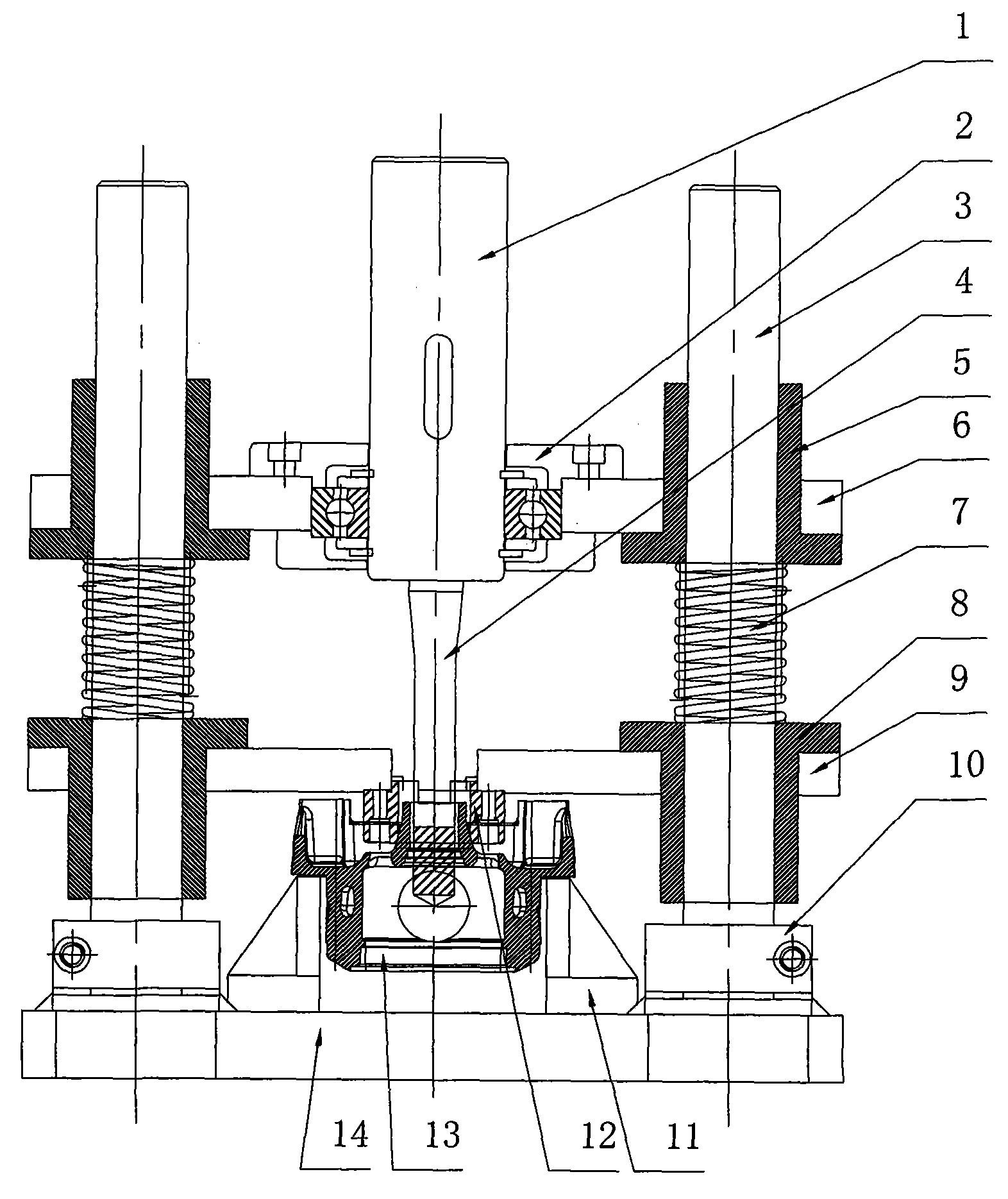

[0015] A Danfoss automatic centering and pressing fixture for a cylinder body. Its innovative point is that it consists of a bottom plate 14, a workpiece support positioning seat 11, a centering sleeve 12, a guide post 3, a spring pressing mechanism and a lifting connection seat 2. A workpiece supporting positioning seat is fixed in the middle of the upper part of the bottom plate, and the workpiece supporting positioning seat is formed of symmetrical positioning plates. On its both sides, by seat body 10 symmetrically fixed vertical guide post, on this guide post, all suit spring holding down mechanism, spring holding down mechanism is by the upper slide block 5 that is sleeved on the guide post, lower slide block 8 and The spring 7 therebe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com