Mixing-type plastic pipe extrusion machine head

A plastic pipe, hybrid technology, applied in the field of hybrid plastic pipe extruder head, can solve the problems of plastic product quality not meeting the ideal requirements, uneven mixing of materials, uneven plasticization of melt, etc., to achieve production High-quality plastic pipes, improve the effect of plasticization, and ensure the effect of consistent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

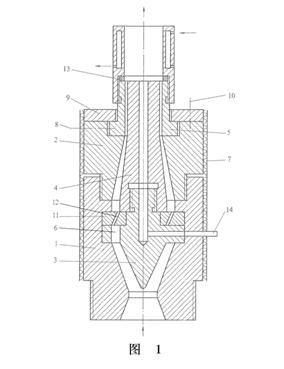

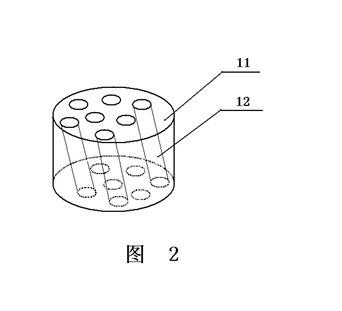

[0015] Such as figure 1 , figure 2 As shown, the head of the hybrid plastic pipe extruder mainly includes a head body 1, a head body 2, a flow divider 3, a mandrel 4, a die 5, and an air intake rod 14. The head body 1, The head body 2, the flow divider 3, the mandrel 4, and the mouth die 5 are combined to form a melt channel 6. The outside of the head body 1 and the head body 2 is provided with a heating ring 7. The head body 2 It is connected with the die 5 by an adjusting screw 8, and the outside of the die body 2 and the die 5 is provided with a pressure ring 9, and the pressure ring 9 is connected with the die body 2 by a fixing screw 10; A mixer 11 is provided between the head body 1 and the splitter 3. The mixer 11 is a cylinder with several through holes 12, and the through hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap