Methanol or dimethyl ether and method for preparing dimethylbenzene by using methylbenzene

A technology of dimethyl ether and xylene, which is applied in the field of preparation of p-xylene, and can solve the problems of low yield of xylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

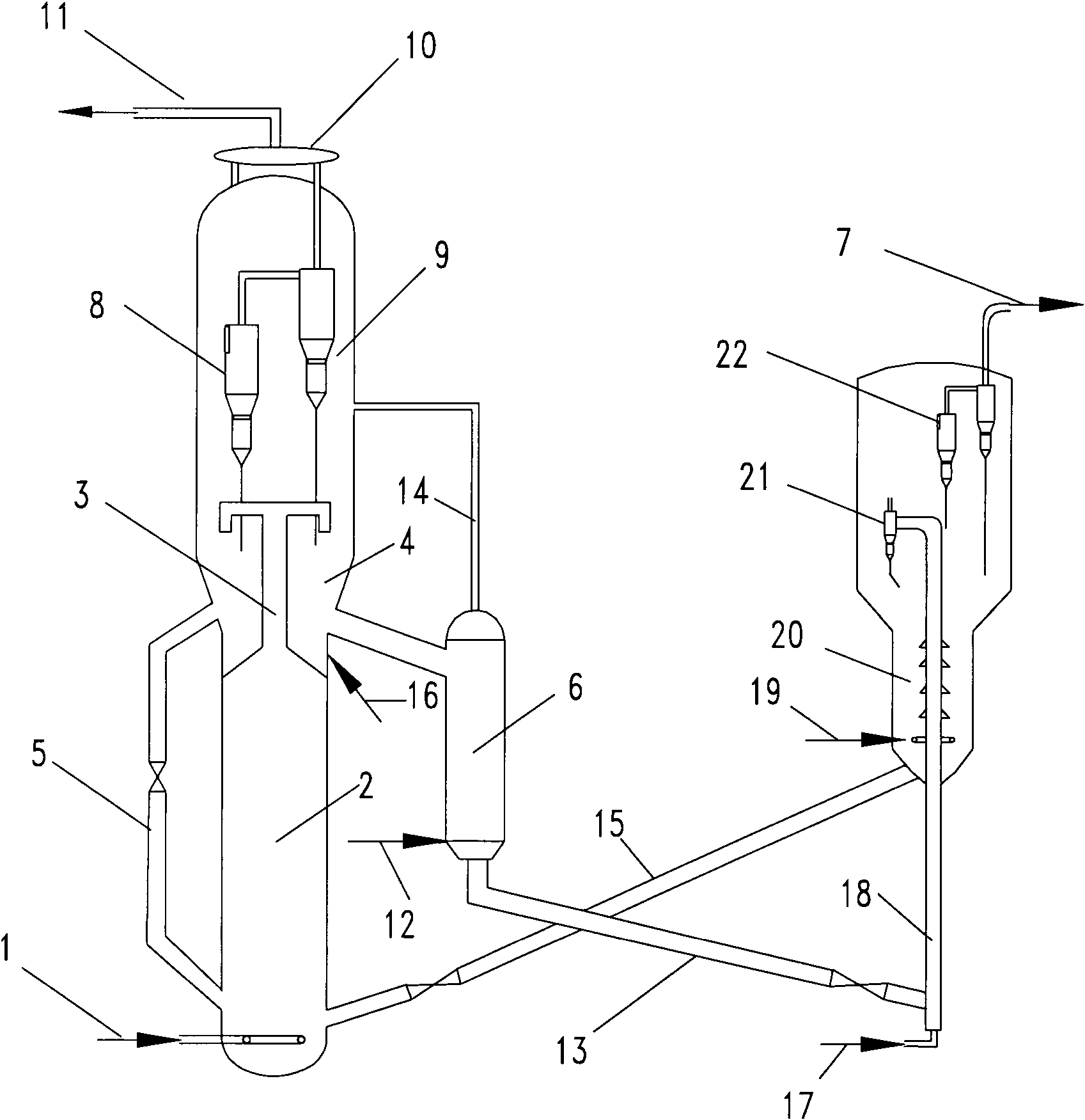

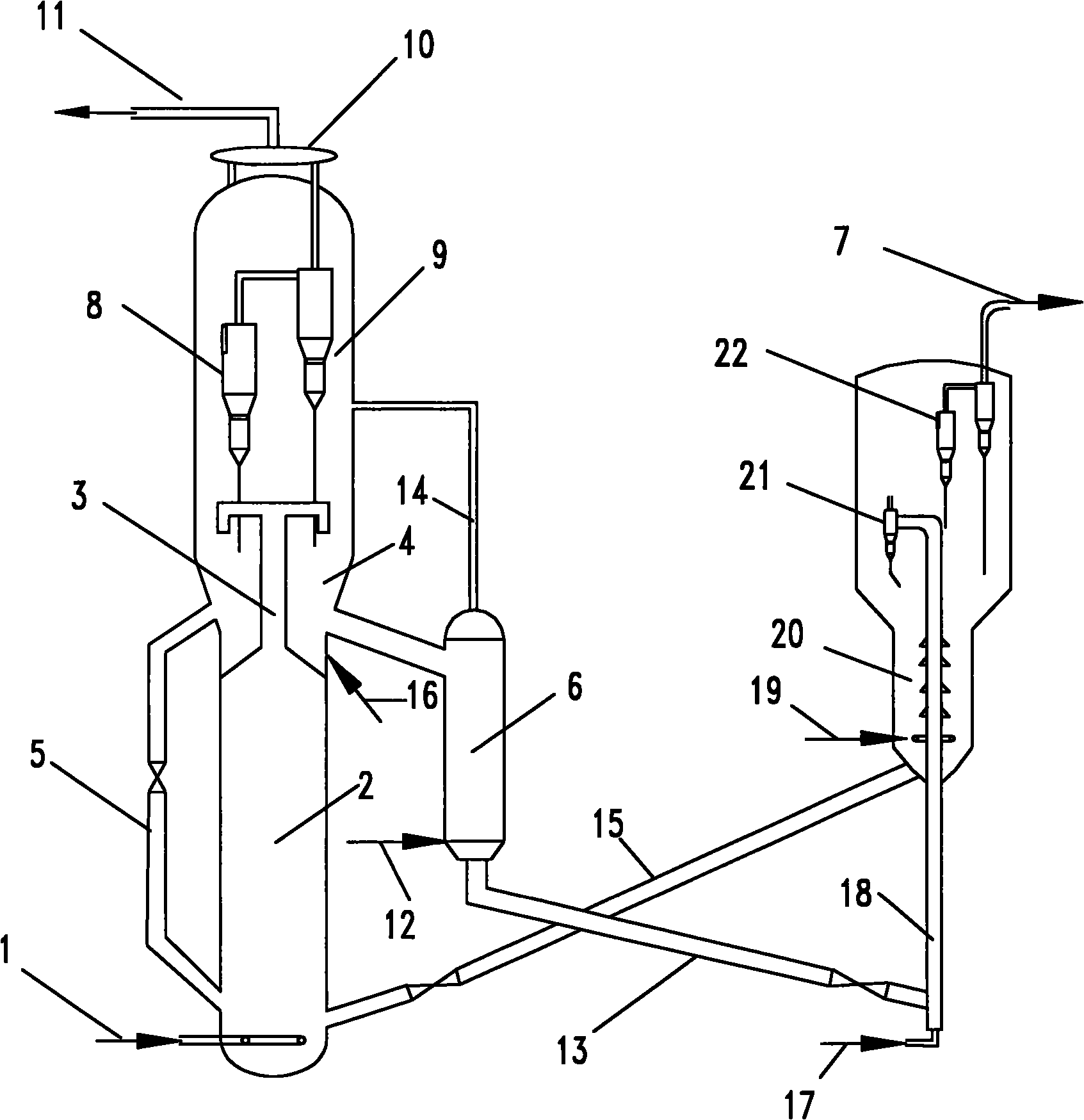

[0024] in such as figure 1 On the reaction device shown, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 20, methanol and toluene enter the reaction zone of the fast fluidized bed reactor, and contact with the catalyst to generate a product stream including xylene. After gas-solid separation, the product stream enters the separation section, and the catalyst enters the second dense phase bed. Be that 75% toluene (all the other are steam) contact with mass fraction, the catalyst of the second dense phase bed is divided into two parts, and 60% returns to described reaction zone, and 40% enters stripper, after steam stripping Enter the regenerator for regeneration, and the catalyst regenerated by the regenerator returns to the reaction zone, and the regenerator type is a riser. The weight ratio of toluene to methanol is 1:1, and the bed density in the reaction zone of the fluidized bed reactor is 150 kg / m 3 , the bed density of the second dense bed is 200 kg / m 3, T...

Embodiment 2

[0026] According to the conditions and steps described in Example 1, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 200, methanol and toluene enter the reaction zone of the fast fluidized bed reactor, and contact with the catalyst to generate a product stream including xylene. After gas-solid separation, the product stream enters the separation section, and the catalyst enters the second dense phase bed. Contact with toluene (all the rest are water vapor) that mass fraction is 75%, the catalyst of the second dense phase bed is divided into two parts, and 90% returns to described reaction zone, and 10% enters stripper, after steam stripping Enter the regenerator for regeneration, and the catalyst regenerated by the regenerator returns to the reaction zone, and the regenerator type is a riser. The weight ratio of toluene to methanol is 6:1, and the bed density in the reaction zone of the fluidized bed reactor is 50 kg / m 3 , the bed density of the second dense bed i...

Embodiment 3

[0028] According to the conditions and steps described in Example 1, the catalyst is ZSM-5, SiO 2 / Al 2 o 3 The molar ratio is 100. Methanol, dimethyl ether and toluene enter the reaction zone of the fast fluidized bed reactor and contact with the catalyst to generate a product stream including xylene. After gas-solid separation, the product stream enters the separation section, and the catalyst enters the second The dense phase bed is contacted with 95% toluene (the rest is water vapor) with a mass fraction, and the catalyst in the second dense phase bed is divided into two parts, 80% is returned to the reaction zone, and 20% enters the stripper, passes through water After the steam is stripped, it enters the regenerator for regeneration, and the catalyst regenerated by the regenerator returns to the reaction zone. The regenerator type is a riser. The weight ratio of toluene to methanol and dimethyl ether is 4:1:1, and the bed density in the reaction zone of the fluidized b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap