Shrink-resistance treatment method of wool textiles

A technology of anti-shrinkage treatment and treatment method, which is applied in the treatment of textile materials, fiber treatment, biochemical fiber treatment, etc. It can solve the problems of refractory biodegradation and aquatic biological hazards, and achieve low temperature, low energy consumption, and anti-shrinkage effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

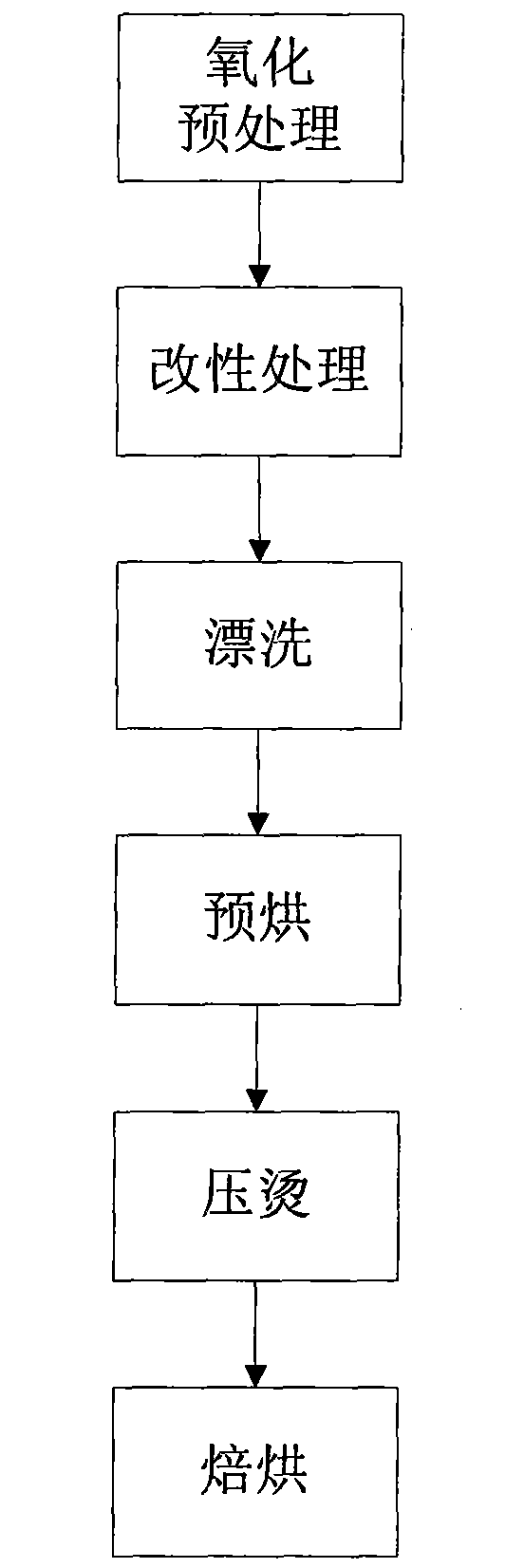

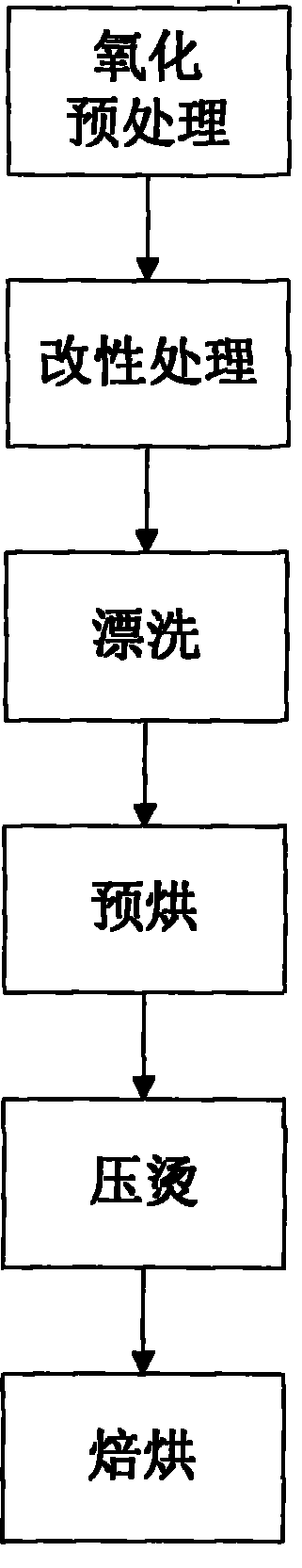

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0020] A kind of anti-shrinkage processing method of woolen fabric of the present invention, concrete steps are:

[0021] (1) Oxidation pretreatment: immerse the woolen fabric in a 20-40% oxidizing solution for oxidation treatment. Treatment conditions: PH: 7-8, temperature 30-50°C, time: 20-30min, bath ratio: 1:30-40, oxidizing agent dosage is 3-5% of cloth weight; the oxidizing agent is preferably hydrogen peroxide or peracetic acid .

[0022] (2) Modification treatment: the finished product of step (1) is immersed in a protease solution for treatment. Treatment conditions: PH: 7-8, temperature 30-60°C, time: 30-50min, bath ratio: 1:30-40, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com