Composite energy storage assisting engine

A composite, engine technology, applied in combustion engines, machines/engines, brakes, etc., can solve the problems of not being able to efficiently provide starting acceleration assistance, inconvenient lubrication, complex structure, etc., to achieve light weight, high reliability, and safe operation. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] Describe in detail below in conjunction with accompanying drawing:

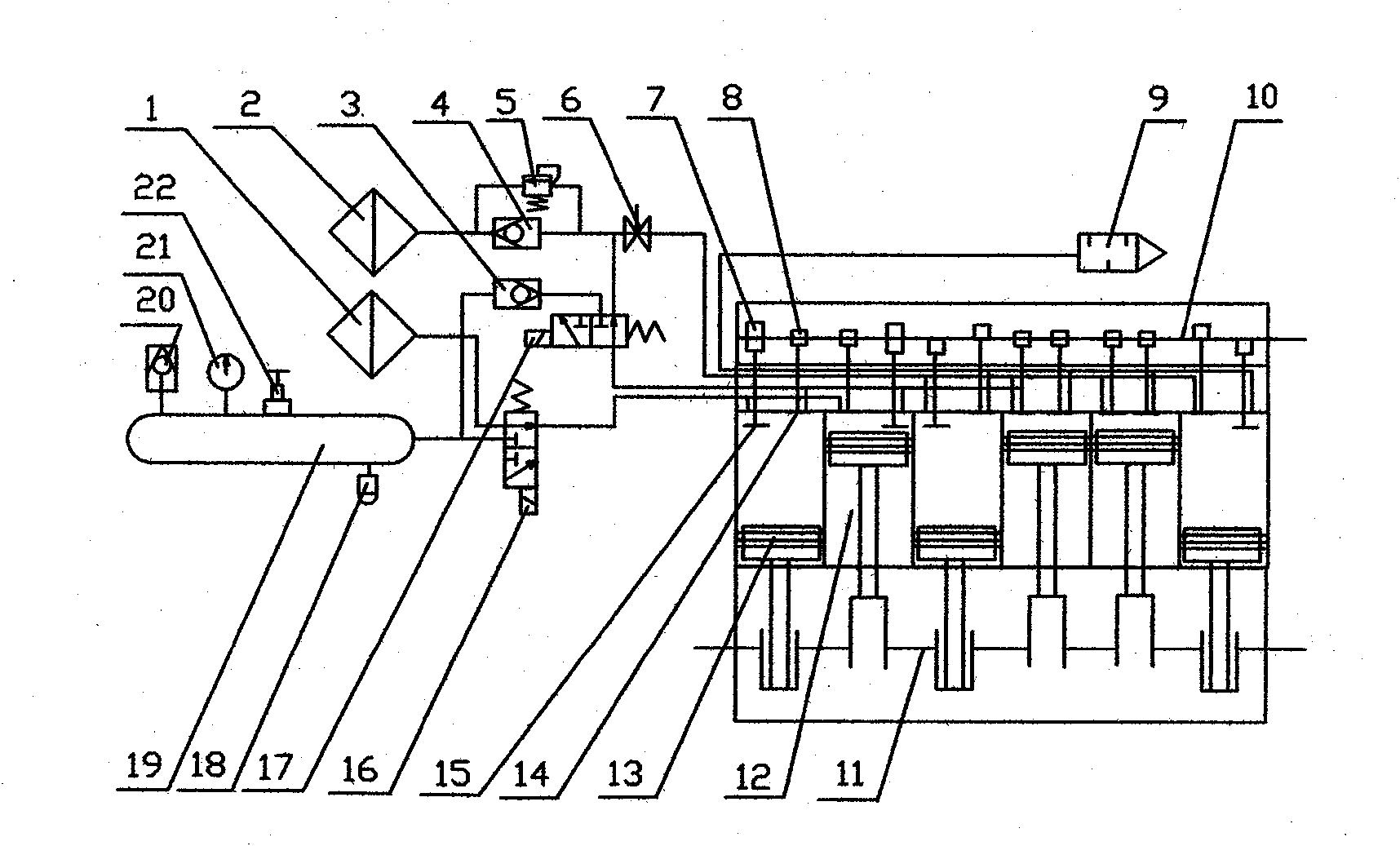

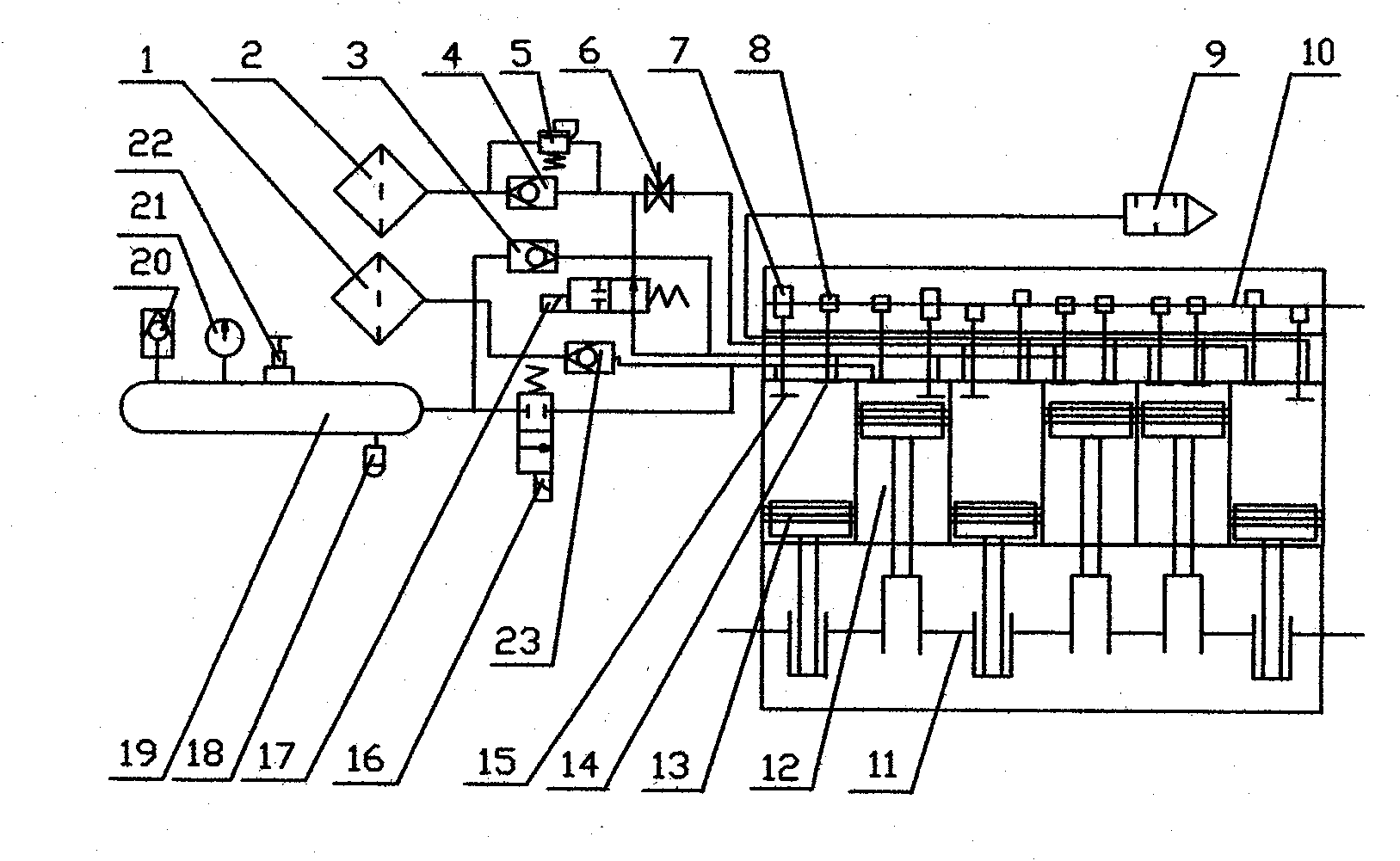

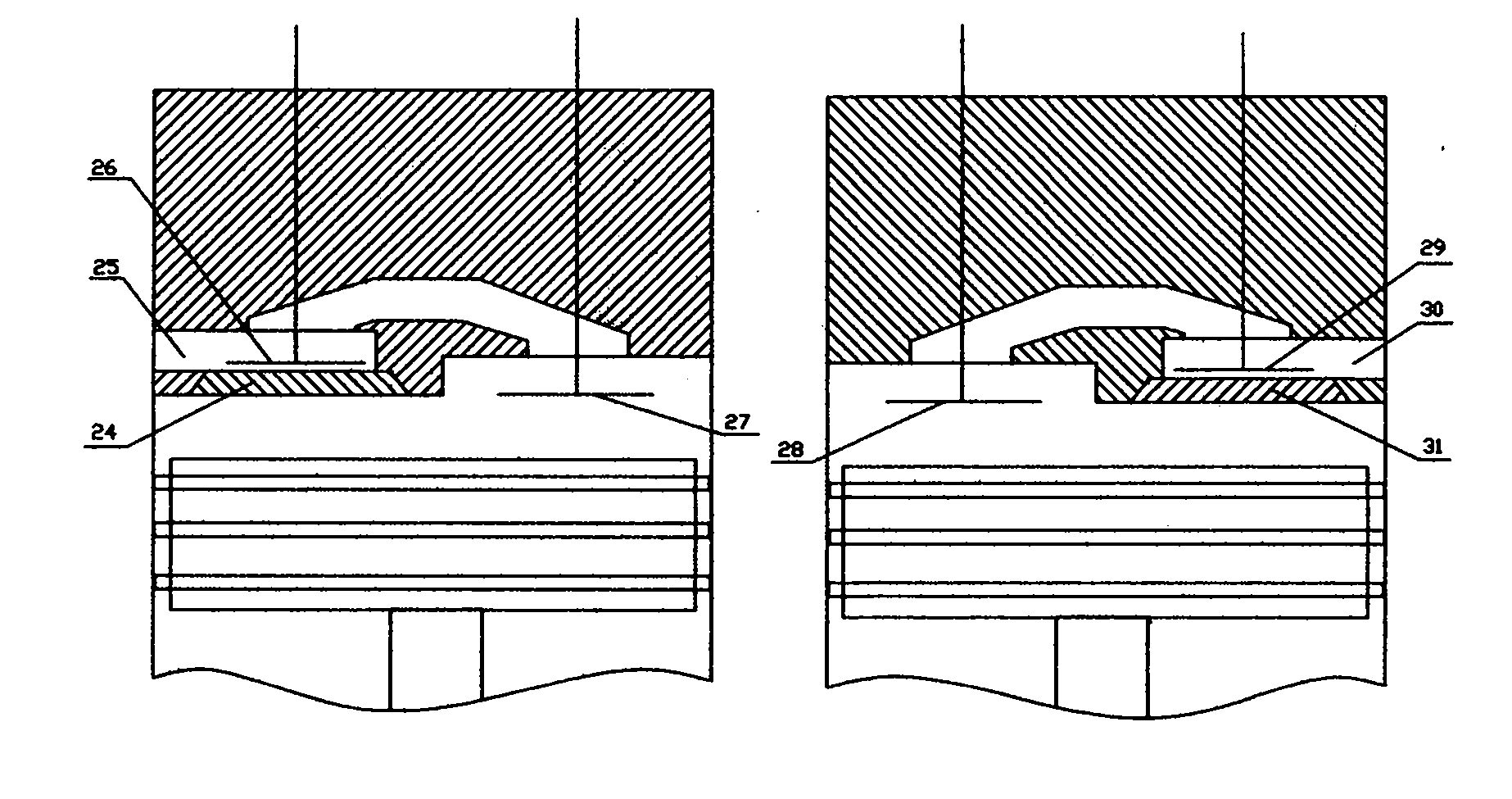

[0015] exist figure 1 Among them, the auxiliary cylinder 12 shares the camshaft 10, the crankshaft 11, the lubrication system, the cooling system, and the timing system with the original internal combustion engine system, and each intake valve cam 7 and exhaust valve cam 8 of the auxiliary cylinder are symmetrically provided with two protrusions , so that the intake and exhaust are changed from one turn of the camshaft to open and close twice, and the protrusions of several auxiliary cylinders are evenly distributed within one turn. The intake valve 15 and the exhaust valve 14 of the auxiliary cylinder are two-stage composite valves or magnetic double sliding valves with two-way sealing ability, which prevent the intake valves from opening under high pressure when the intake and exhaust places are under high pressure. Pistons 13 in several auxiliary cylinders are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com