Upper water-adding humidifier

A humidifier, water-type technology, applied in the direction of heating, air humidification system, lighting and heating equipment, etc., can solve the problems of cumbersome water adding process, high processing cost, complex structure, etc., and achieve simple structure, low cost and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

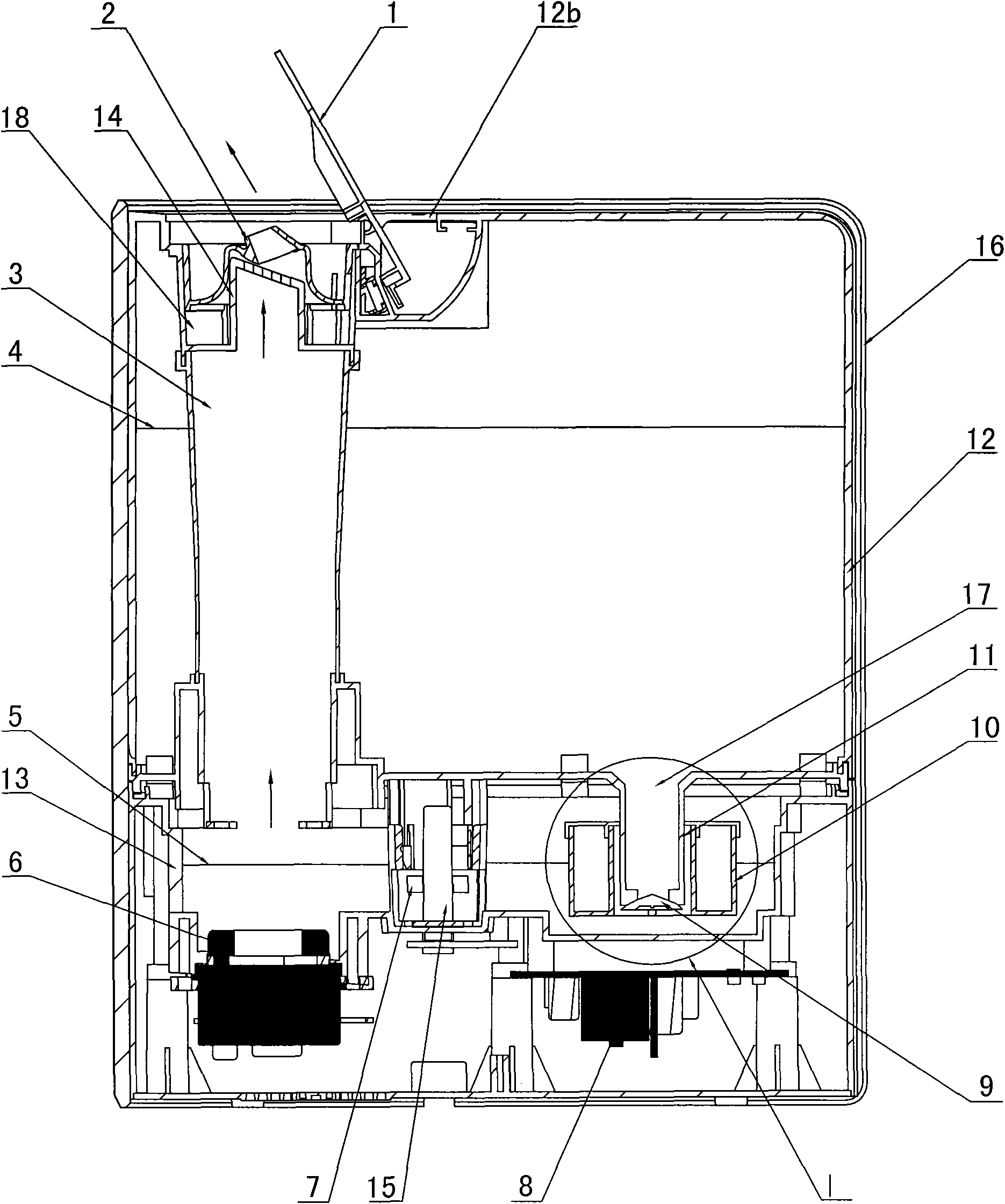

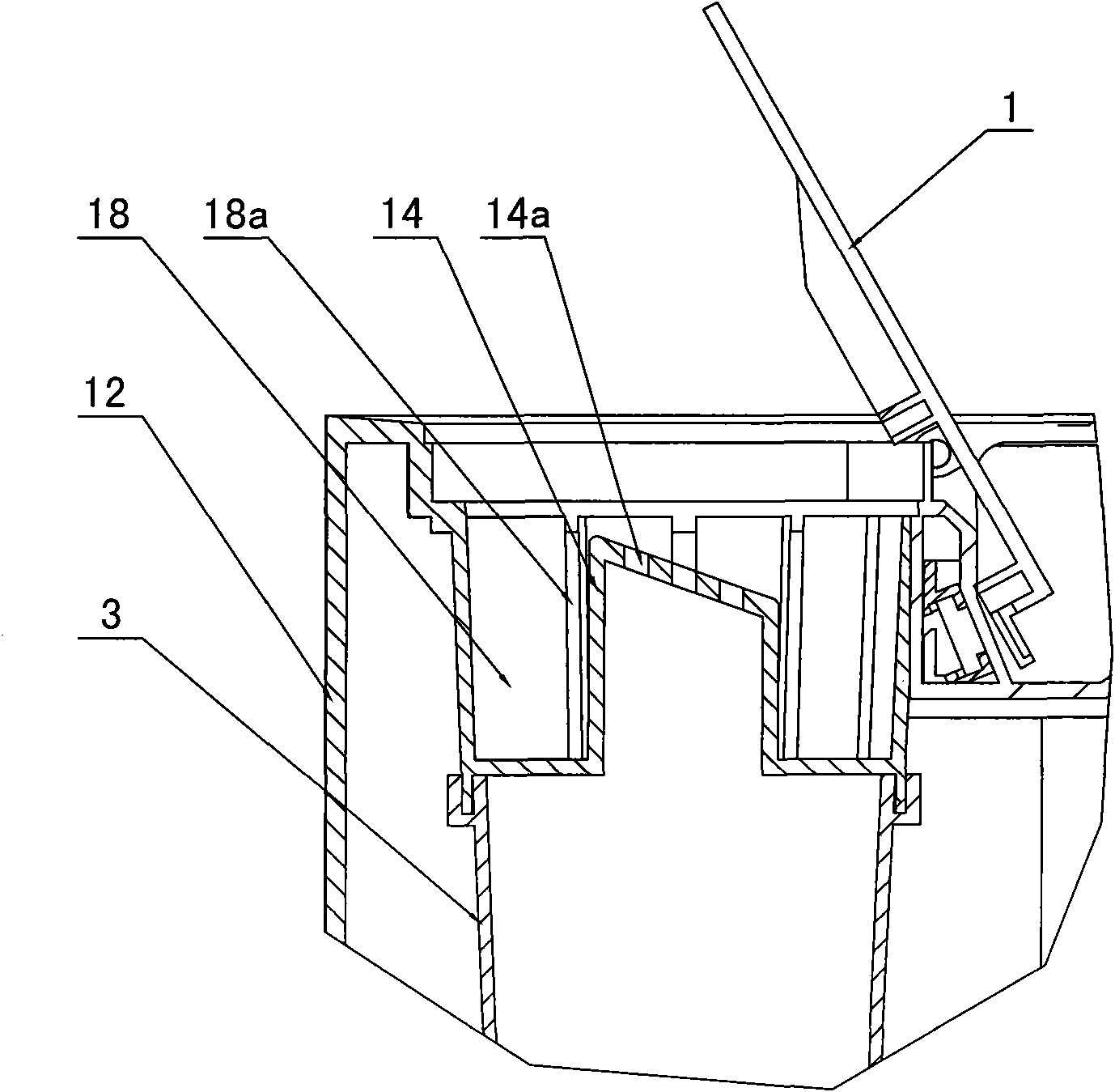

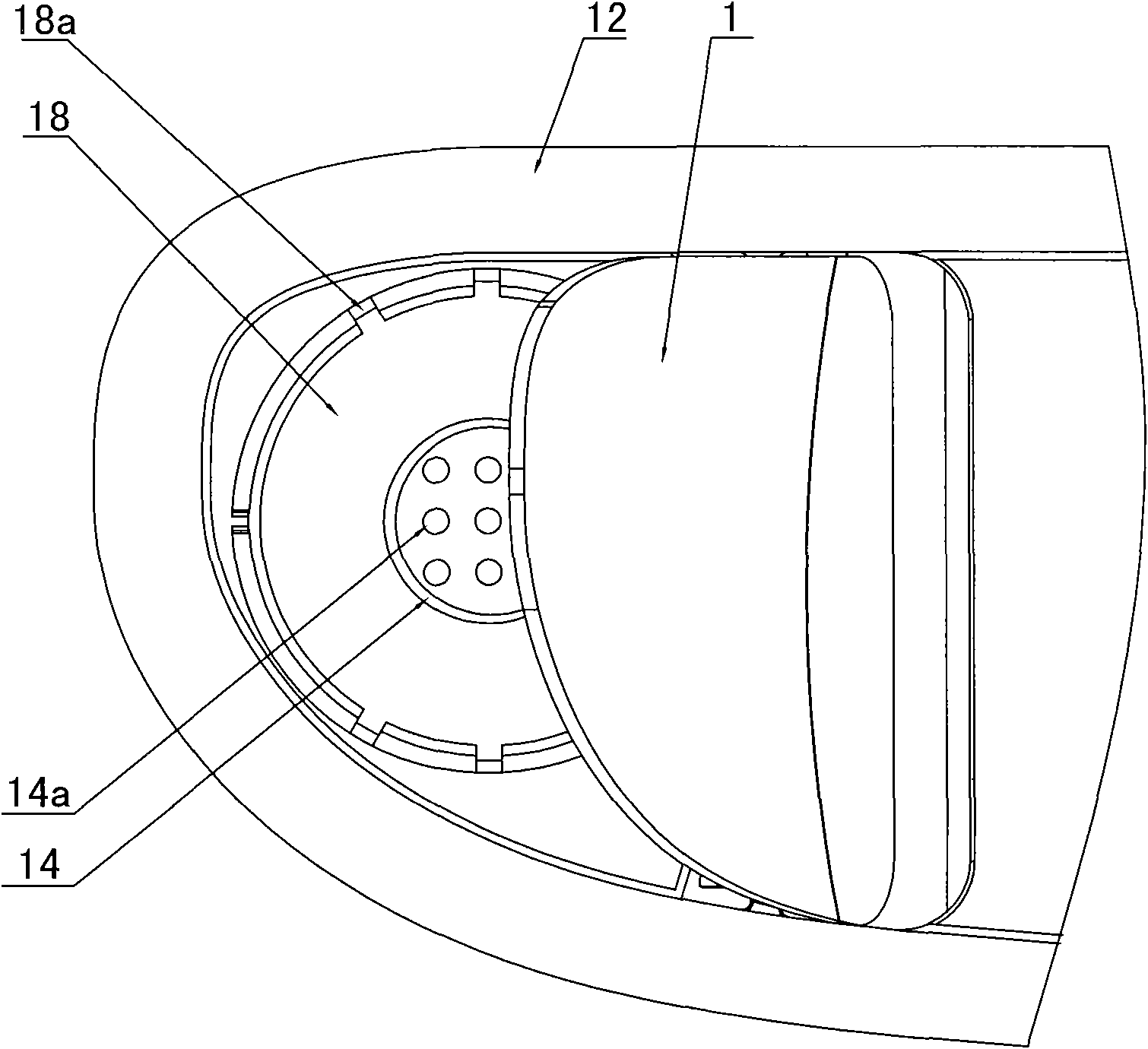

[0037] like Figure 1 to Figure 5 As shown, the top-filling humidifier of the present invention includes a water tank 12, a water tank 13, a transducer 6 and a spray port 14a, wherein the water tank 12 is installed above the water tank 13, and the water tank 12 and the water tank 13 are both accommodated in the shell 16 .

[0038]The top plate 12b of water tank 12 is partly recessed downwards to form a water-filling tank 18. The side wall of water-filling tank 18 has a grid-shaped water-filling port 18a communicating with water tank 12, and water is added in water tank 12 through water-filling port 18a. A water outlet 17 is provided at the bottom of the water tank 12, and the water outlet 17 communicates with the water tank 13 through a water level control device.

[0039] See Figure 4 , the water level control device is made up of water pipe 11, first piston part 9 and buoyancy part 10, and water pipe 11 is vertically arranged, and its upper end pipe mouth is communicated ...

Embodiment 2

[0048] like Figure 6 to Figure 9 As shown, the difference from Embodiment 1 is that the water tank 12 is detachably installed above the water tank 13, and a valve assembly for preventing liquid from flowing out of the tank is provided at the upper end of the water pipe 11. The valve assembly includes a sealing part 11b arranged on the inner wall of the water diversion pipe 11, a second piston part 19 matched with the sealing part 11b, and a top post 20 pierced in the water diversion pipe 11. The upper end of the top post 20 is connected to the second The piston parts 19 are connected to each other, and the lower end protrudes from the water diversion pipe 11 to connect with the lower cover plate 10d of the buoyancy part. In addition, the distance between the sealing portion 11 b and the inner bottom surface of the water tank 13 is smaller than the distance between the second piston portion 19 and the inner bottom surface of the water tank 13 .

[0049] In this way, when the ...

Embodiment 3

[0053] like Figure 10 and Figure 11 As shown, the difference from Embodiment 2 is that the top post 20 includes an upper top post 20a and a lower top post 20b which are in contact with each other up and down, and the upper top post 20a is supported by a support frame 21 arranged in the water diversion pipe 11. 9 and the second piston portion 19 are respectively provided on the upper top post 20a and the lower top post 20b. The buoyancy part 10 is separated from the water tank 12 by decomposing the top column 20 in the second embodiment into two parts. When mentioning water tank 12 to add water like this, water tank 12 becomes comparatively light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com