Adjustable clamp for delivery valve matching part sealing test

A technology of sealing test and oil outlet valve, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of high technical requirements for oil outlet valve pair production, inability to meet product batch requirements, and increase in production cost. Achieve compact structure, meet the needs of multi-variety and mass production, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

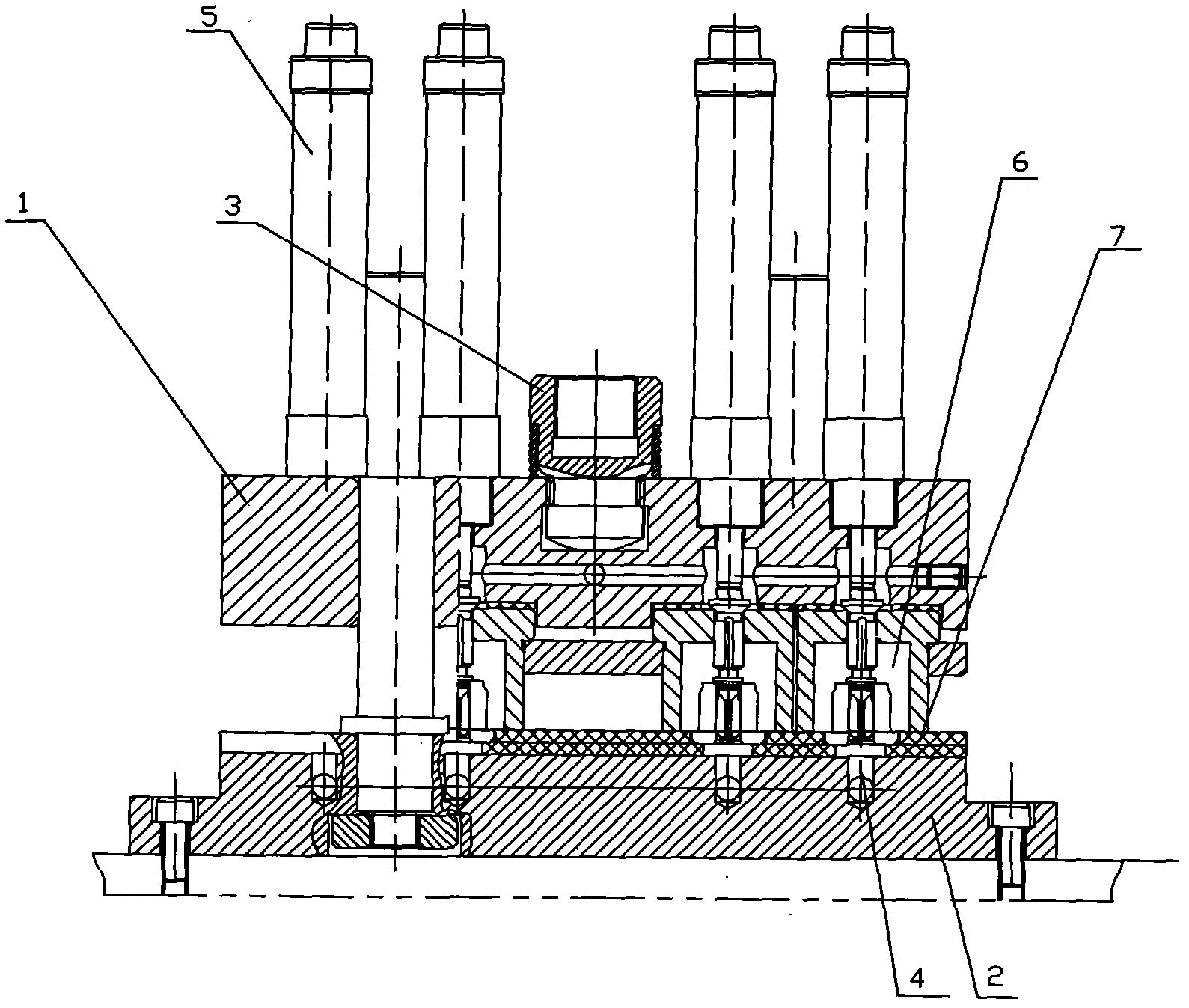

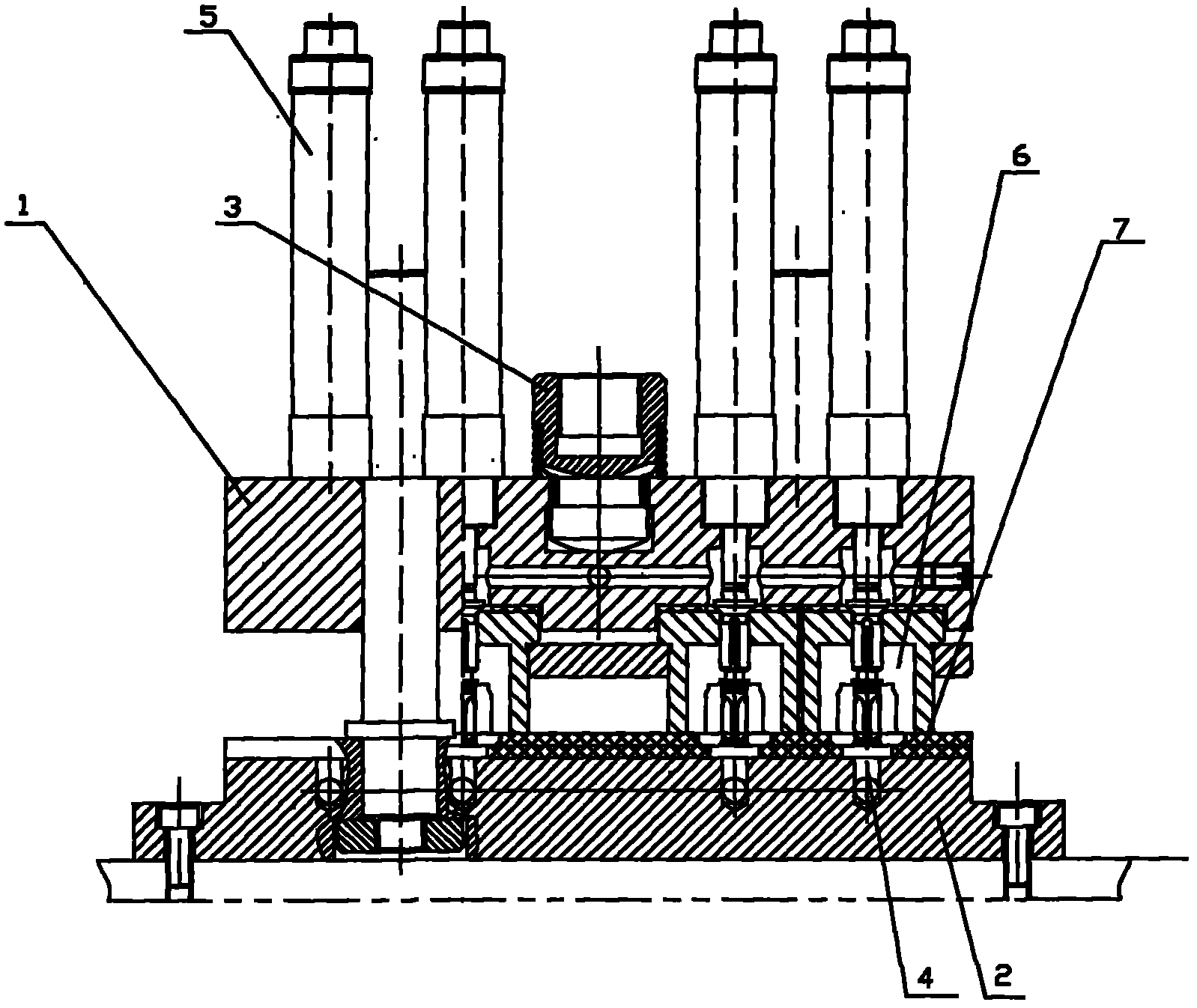

[0008] An adjustable jig for the sealing test of an oil outlet valve pair, comprising an upper clamp body 1 and a lower clamp body 2, the upper clamp body 1 is provided with an air inlet 3, and the lower clamp body 2 is provided with several air outlets 4, The upper clamp body 1 is provided with a cylinder 5 corresponding to each air outlet 4, and a sealing chamber 6 is formed between the cylinder 5 and the air outlet 4, and a sealing plate 7 is arranged outside the sealing chamber 6, and the oil outlet valve assembly is arranged in the sealing chamber 6 , one end is connected to the cylinder 5, the other end is connected to the air outlet 4, and the air inlet 3 is connected with an air inlet pipe and communicated with each sealed cavity 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com