Method and device for controlling shipbuilding production flow

A production process and control method technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as inability to adjust production plans in time, difficulties in production organization, and long production preparation cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

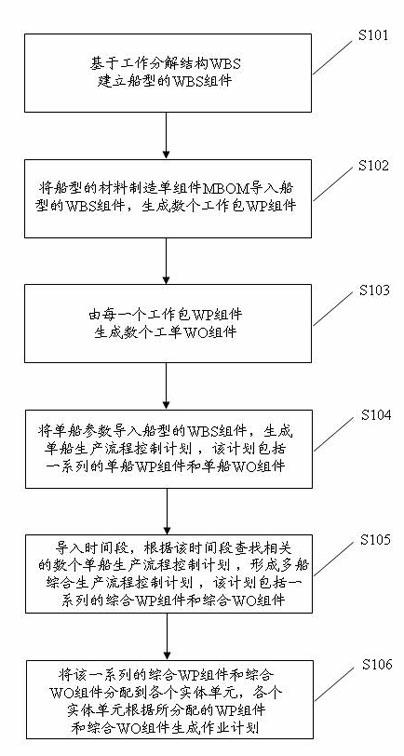

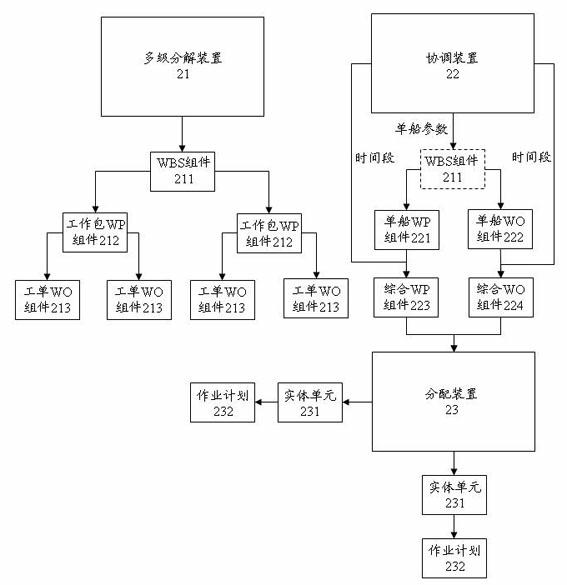

[0036] refer to figure 1 Shown, the present invention discloses a kind of shipbuilding production process control method, comprises the following steps:

[0037] S101. Establish ship type WBS components based on the work breakdown structure WBS. This WBS component corresponds to the mid-schedule plan.

[0038] S102. Import the ship-type material manufacturing single-component MBOM into the ship-type WBS component, and generate several work package WP components.

[0039] S103. Generate several work order WO components from each work package WP component. In one embodiment, the work order WO component is associated with a series of parameters, the series of parameters include: product code, bullet, drawing number, type of work, work area, team, personnel, fixed working hours, planned start time, actual working hours .

[0040] S104. Import the single ship parameters into the WBS component of the ship type to generate a single ship production process control plan. The single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com