Work transfer apparatus for press machine, and work transfer unit

A technology for conveying devices and presses, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of rising manufacturing costs, increasing types, and complex structures of workpiece conveying devices, and achieve simplified structures, improved maintainability, increased The effect of a large range of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

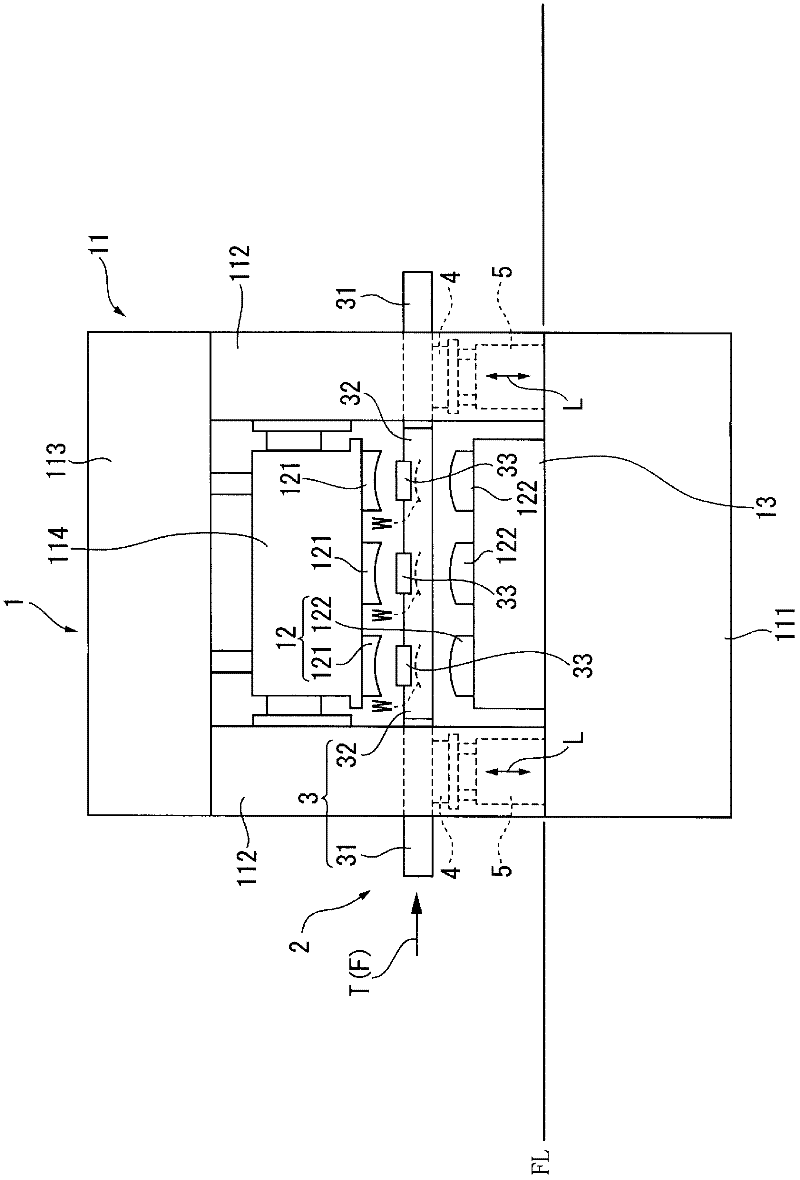

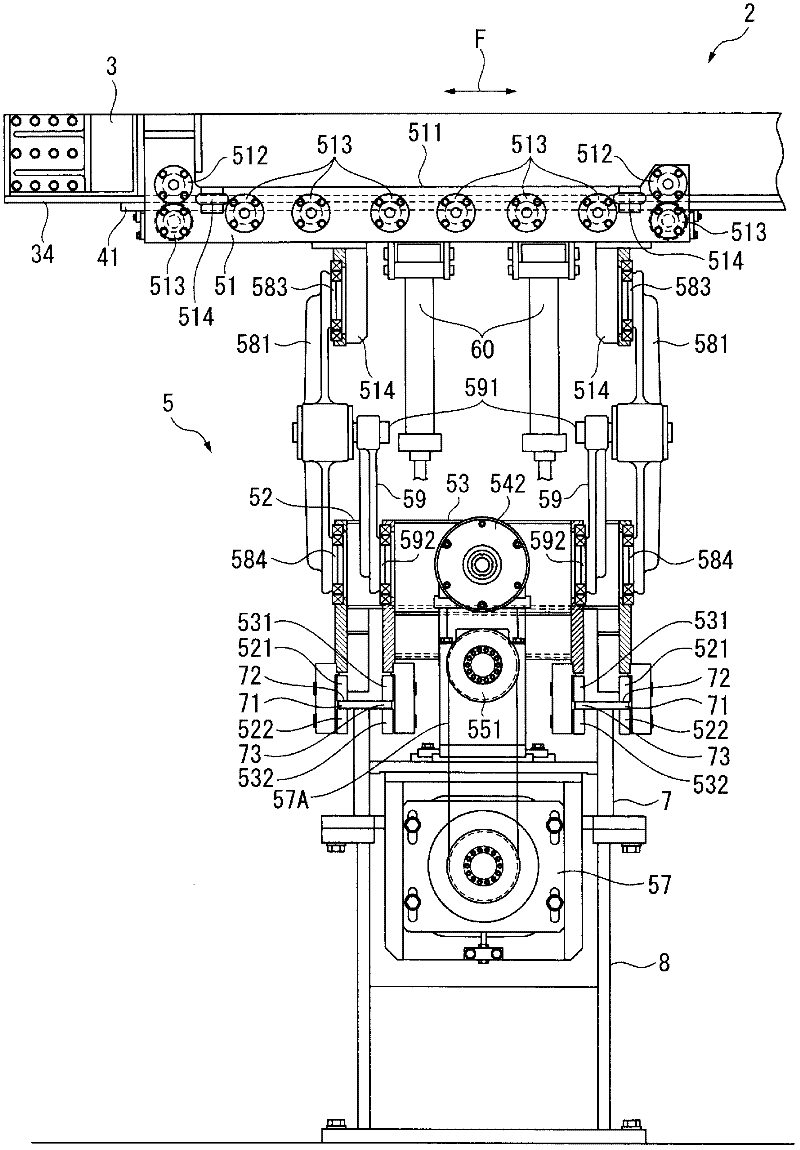

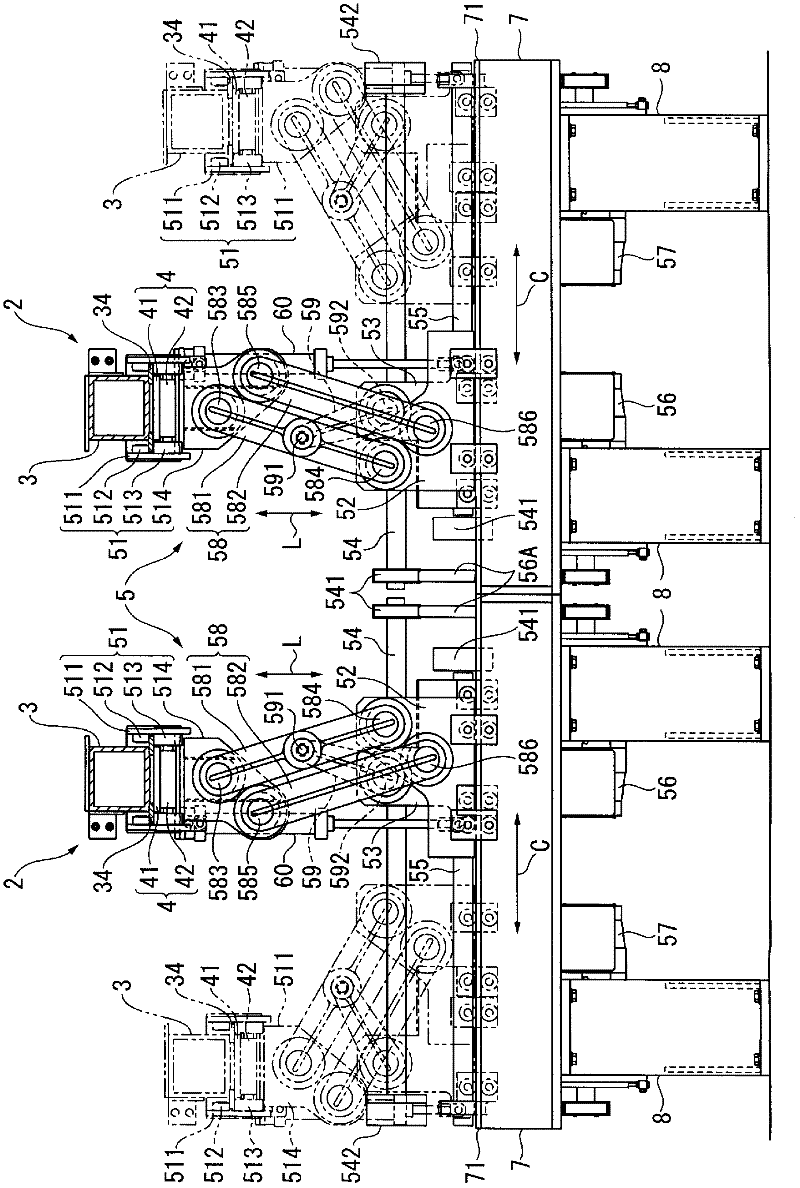

[0065] First, use figure 1 The overall structure of the transfer press (press) 1 according to the first embodiment of the present invention will be described.

[0066] The multi-station press 1 has: a press main body 11, which has a base 111, a column 112, a crown portion 113, and a slider 114; a mold 12, which has an upper mold 121 and a lower mold 122; a movable cross brace 13, and The transfer press 1 as described above is provided with a transfer feeder (work transfer device) 2 .

[0067] In the press main body 11, a base 111 serving as a base of the transfer press 1 is provided under the floor FL, and upright columns 112 are erected at four corners of the base 111, which is substantially rectangular in plan view (see Figure 6 and Figure 7 ). figure 1 The middle figure shows two upright columns 112 erected on the upstream and downstream sides of the conveyance direction of the workpiece W (hereinafter referred to as the workpiece conveyance direction) T. As shown in F...

no. 2 approach 〕

[0111] Below, based on Figure 8 ~ Figure 10 A second embodiment of the present invention will be described.

[0112] In the first and second carrying devices 52 and 53 of the first embodiment described above, the upper guide rollers 521 and 531 and the lower guide rollers are provided so as to sandwich the first and second guide parts 72 and 73 of the guide rail 71 up and down. 522, 532, but in this embodiment, side guide rollers 523, 533 that abut against the side end surfaces of the guide rail 71 are further provided to make the first and second carrying devices 52, 53 move in the clamping direction C Be guided more reliably. In addition, it goes without saying that the above-mentioned side guide rollers 523 and 533 may also be used in the first embodiment.

[0113] In addition, in the first embodiment, each link 581, 582 constituting the parallel link 58 has a structure in which a rib is erected in the longitudinal direction at the center of the flat portion, but the str...

no. 3 approach

[0118] In the aforementioned first embodiment, the linear motor 4 for feeding is provided as the feeding drive mechanism of the rod 3 , and the rod 3 is reciprocated in the feeding direction F by the linear motor 4 for feeding.

[0119] In contrast, in the third embodiment, as Figure 11 As shown, the timing belt mechanism 9 is used as the feed drive mechanism to reciprocate the rod 3 in the feed direction F, which is different from the first embodiment described above.

[0120] Specifically, the timing belt mechanism 9 is provided between the rod 3 and the support portion 51 , and the entire timing belt mechanism 9 is supported by the support portion 51 . The timing belt mechanism 9 is configured to include: a timing belt 91 having a terminal end fixed to the rod 3 and having both ends fixed between the rod 3 and the support portion 51 ; and guide pulleys 92 , 93 for guiding the timing belt 91 . , the driven pulley 95 sharing the rotating shaft 94 with the guide pulley 93, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com