Method for controlling material winding speed

A technology of coiling speed and control method, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of not being able to adjust the coiling shaft speed in time, material stretching and deformation, and high detection costs, and achieve Improve detection accuracy and calculation speed, improve production efficiency, and avoid stretching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

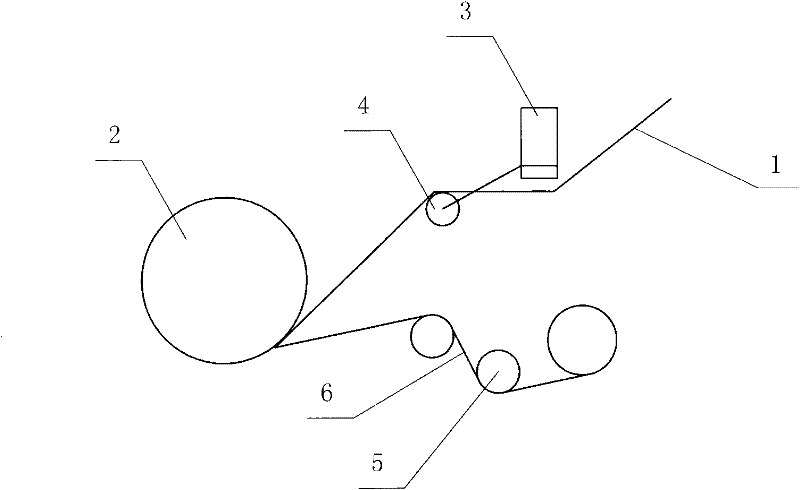

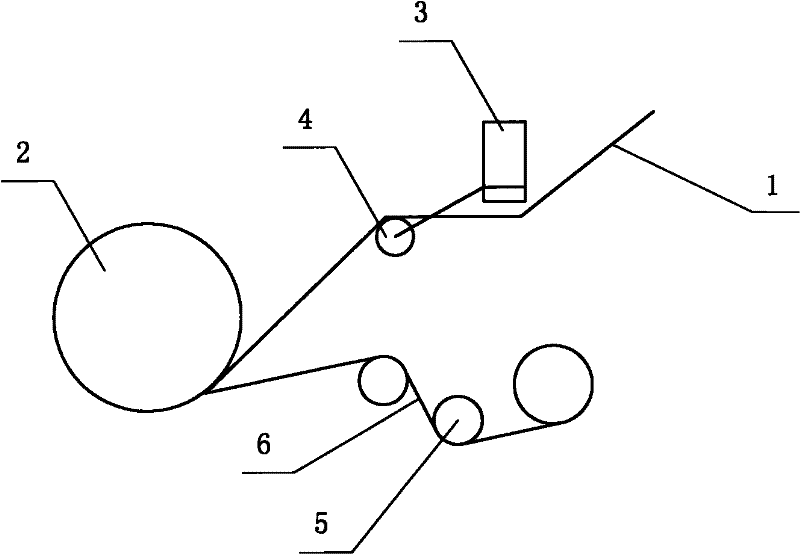

[0042] Example 1, such as figure 1 As shown, the method for controlling the speed of material coiling is applied to the rubber tire manufacturing process, and the blank semi-finished material (such as steel cord, inner liner or belt layer) is transported to the coiling roller 2 through the conveyor belt 1 Complete the coiling with a pad cloth into a roll.

[0043] The floating roller 4 of the speed adjusting device 3 is suspended and supported under the material to dynamically adjust the rotational angular velocity ω of the take-up roller 2 .

[0044] The rotational angular velocity ω of take-up roller 2 conforms to the expression ω=V / C, wherein,

[0045] V is the linear velocity of the conveyor belt 1, and V is set as a constant value;

[0046] C is the circumference of the material when it is coiled on the take-up roller 2, C=2лr, r is the radius of the material coiled, and C is a variable that changes in real time.

[0047] During the material coiling process, an angle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com