Nano modified halogen-free wear resistant cable material and its preparation method

A nano-modification, cable material technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of environmental safety hazards, wear resistance can not meet the requirements of the use environment, etc., to achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

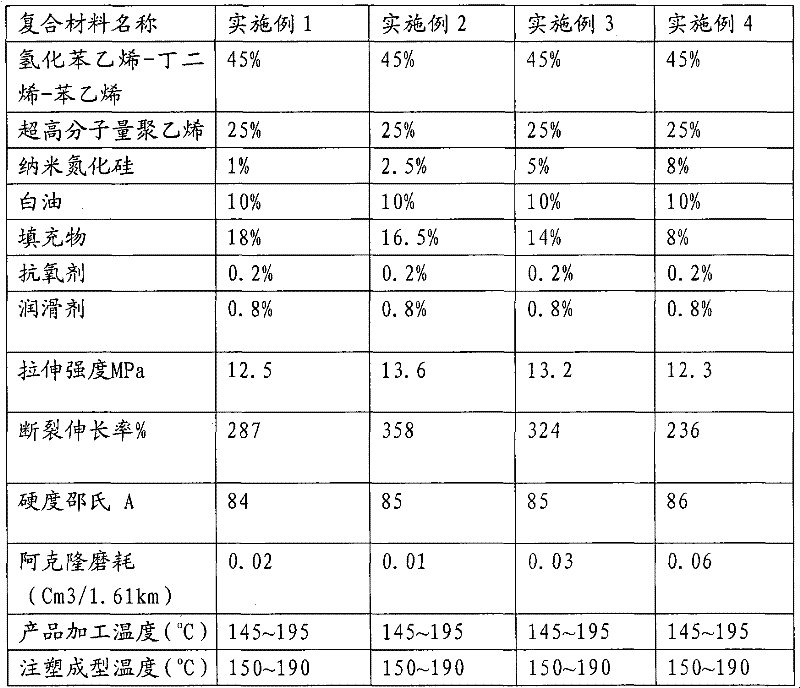

Examples

preparation example Construction

[0027] The invention provides a preparation method of a nano-modified halogen-free wear-resistant cable material, which comprises the following steps:

[0028] 1. Weigh raw materials according to the formula;

[0029] 2. Mix the mixture prepared in 1 in the mixing tank for 5-20 minutes; the speed is 200-600 rpm;

[0030] 3. Put the mixed raw materials in a twin-screw extruder for plasticization and granulation. The processing temperature is 140-1250°C in the first zone, 150-160°C in the second zone, 150-170°C in the third zone, and 160-160℃ in the fourth zone. 185°C, 175-195°C in the fifth zone, 180-205°C in the sixth zone, and 170-190°C in the seventh zone.

[0031] 4. In the production process, the rubber is extruded from the extruder, drawn, water-cooled, dried, pelletized and packaged.

[0032] For the convenience of further understanding of the present invention, now in conjunction with specific embodiment the present invention is described in detail:

[0033] In an em...

Embodiment 1

[0035] Hydrogenated styrene-butadiene-styrene weight percent 45%, polyethylene 25%, nano-silicon nitride 1%, white oil 10%, filler 15%, antioxidant 0.2%, lubricant 0.8%, will The above materials are pre-mixed in a mixing tank for 10 minutes, and then extruded and granulated by twin-screw. The processing temperature is 145°C in the first zone, 155°C in the second zone, 170°C in the third zone, 175°C in the fourth zone, 185°C in the fifth zone, 195°C in the sixth zone, and 190°C in the seventh zone.

Embodiment 2

[0037] Hydrogenated styrene-butadiene-styrene weight percent 45%, polyethylene 25%, nano-silicon nitride 2.5%, white oil 10%, filler 15%, antioxidant 0.2%, lubricant 0.8%, will The above materials are pre-mixed in a mixing tank for 10 minutes, and then extruded and granulated by twin-screw. The processing temperature is 145°C in the first zone, 155°C in the second zone, 170°C in the third zone, 175°C in the fourth zone, 185°C in the fifth zone, 195°C in the sixth zone, and 190°C in the seventh zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com