Brewing method of salubrious malt yellow wine

A technology of refreshing rice wine, applied in the brewing field of refreshing malt rice wine, which can solve the problems of complicated rice wine production process, heavy operation, hindering the mechanization and automation of rice wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

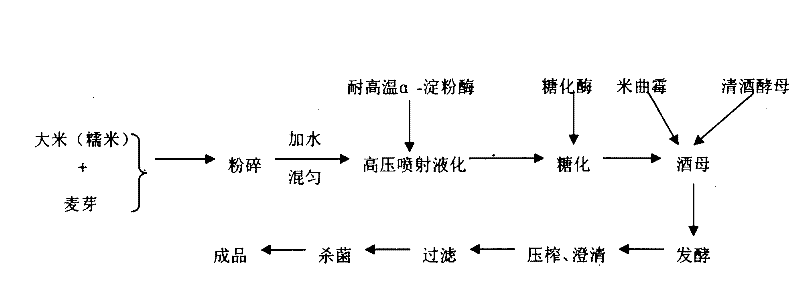

Image

Examples

Embodiment 1

[0017] Formula: (based on the total mass of rice (glutinous rice) and malt as 100%) rice (glutinous rice) 70%, barley malt 30%, a-amylase 0.3%, glucoamylase 0.3%, koji 10%, yeast 15%, Water 150%.

[0018] Process: Grinding rice (glutinous rice) and barley malt respectively to obtain uniform granules with a crushing degree of 60 mesh; weighing rice (glutinous rice), barley malt and water and other raw materials according to the formula and mixing them thoroughly; taking 0.3% of a-amylase High-pressure jet liquefaction method to liquefy raw materials; after rapid cooling, add 0.3% glucoamylase, 10% koji and 5% sake yeast, mix thoroughly, and ferment at 15°C-20°C for 20-25 days; use plate and frame press to remove distiller's grains , filter, sterilize, and drink the finished product.

Embodiment 2

[0020] Formula: (based on the total mass of rice (glutinous rice) and malt as 100%) rice (glutinous rice) 80%, barley malt 20%, a-amylase 0.5%, glucoamylase 0.5%, koji 20%, yeast 10%, Water 250%.

[0021] Process: Grind rice (glutinous rice) and barley malt respectively to obtain uniform granules with a crushing degree of 90 mesh; weigh rice (glutinous rice), barley malt and water according to the formula and mix them thoroughly; take 0.3% of a-amylase High-pressure jet liquefaction method to liquefy raw materials; after rapid cooling, add 0.3% glucoamylase, 5% Aspergillus oryzae culture solution and 10% sake yeast culture solution, mix well, and ferment at 15°C-20°C for 15-20 days; The frame is pressed to remove distiller's grains, filtered, sterilized, and the finished product is drunk.

Embodiment 3

[0023] Formula: (based on the total mass of rice (glutinous rice) and malt as 100%) rice (glutinous rice) 70%, barley malt 30%, a-amylase 0.8%, glucoamylase 0.8%, koji 15%, yeast 20%, Water 250%.

[0024] Process: Grind rice (glutinous rice) and barley malt respectively to obtain uniform particles with a crushing degree of 120 mesh; weigh rice (glutinous rice), barley malt and water according to the formula and mix them thoroughly; take 0.4% of a-amylase High-pressure jet liquefaction method to liquefy raw materials; add 15% of Aspergillus oryzae culture solution and 15% of activated sake yeast culture solution, mix well, and ferment for 10-15 days under temperature control at 20°C-25°C; remove distiller's grains by means of plate and frame pressing , filter, sterilize, and drink the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com