Centralized automatic control system for electric roller

An automatic control system, electric roller technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of solving real-time and meeting the requirements of collaborative control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

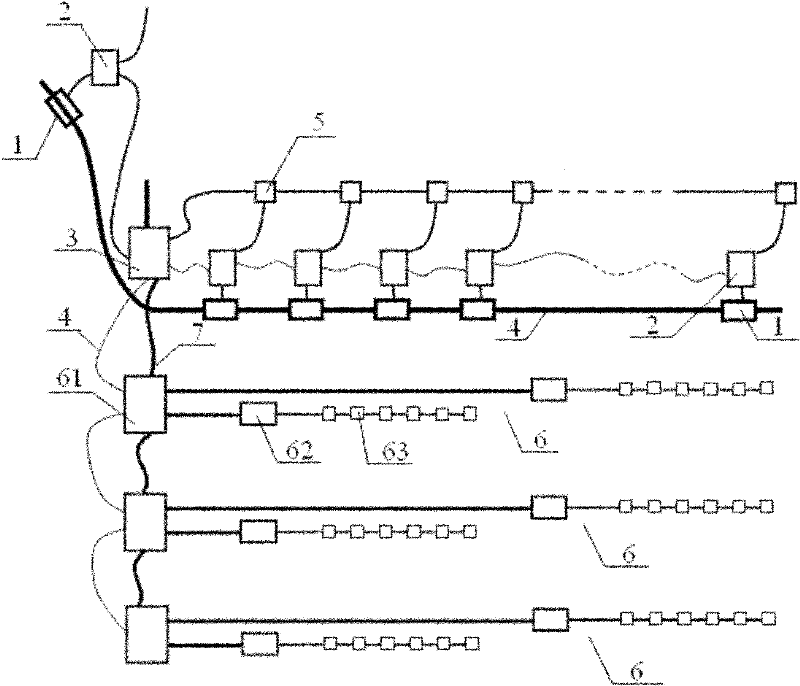

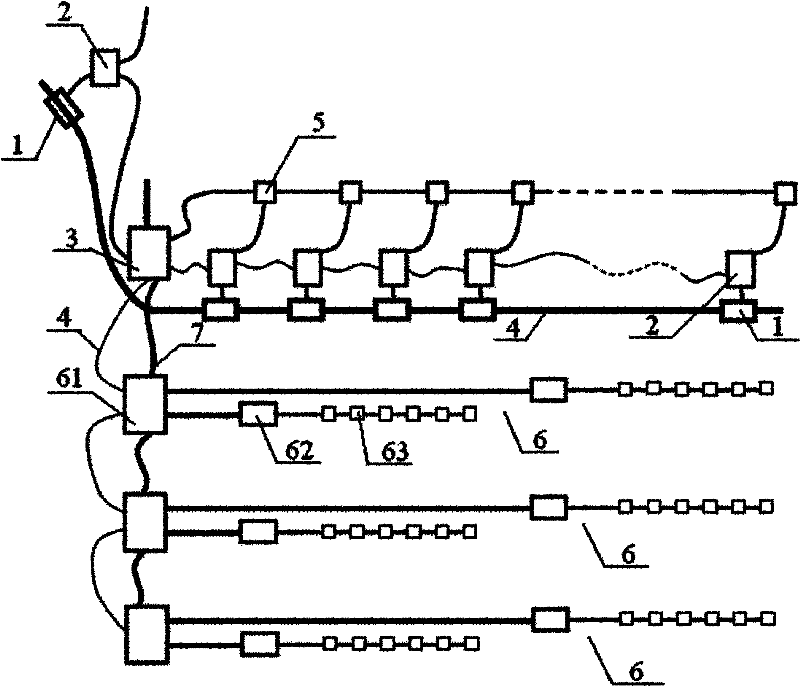

[0020] A centralized automatic control system for electric rollers, its structure is as follows figure 1 As shown, the system includes a conveyor 1, a frequency conversion control box 2, a centralized network control box 3 and a roller control device 6. There are at least 2 conveyors 1, and 14 are provided in this embodiment. Each conveyor 1. Driven by two AC asynchronous motors, one conveyor is set outside the tunnel, and the rest of the conveyors are set inside the tunnel. The conveyors are connected by optical cables 4, and one end of the frequency conversion control box 2 is set with a power tap 5. Each power tap 5 is connected to the network centralized control box 3 via an optical cable. Roller control equipment 6 is provided with three groups, is connected with network centralized control box 3 through optical cable, and roller control equipment 6 comprises wheel control box 61, wheel sub-controller 62 and wheel 63, and wheel control box 61 has optical fiber communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com