Nonaqueous electrolyte battery

A non-aqueous electrolyte and battery technology, applied in the manufacture of non-aqueous electrolyte batteries, electrodes of non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve problems such as current collector deformation, separator damage, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0032]1. First embodiment (example in which the position of the end of the electrode lead is adjusted and the edge of the electrode lead is processed)

[0033] 2. Second embodiment (example where electrode lead end is coated)

no. 3 example

[0034] 3. Third Embodiment (Example Using Another Electrode Lead Connection Method)

[0035] 1. The first embodiment

[0036] 1-1. Overall structure of non-aqueous electrolyte battery

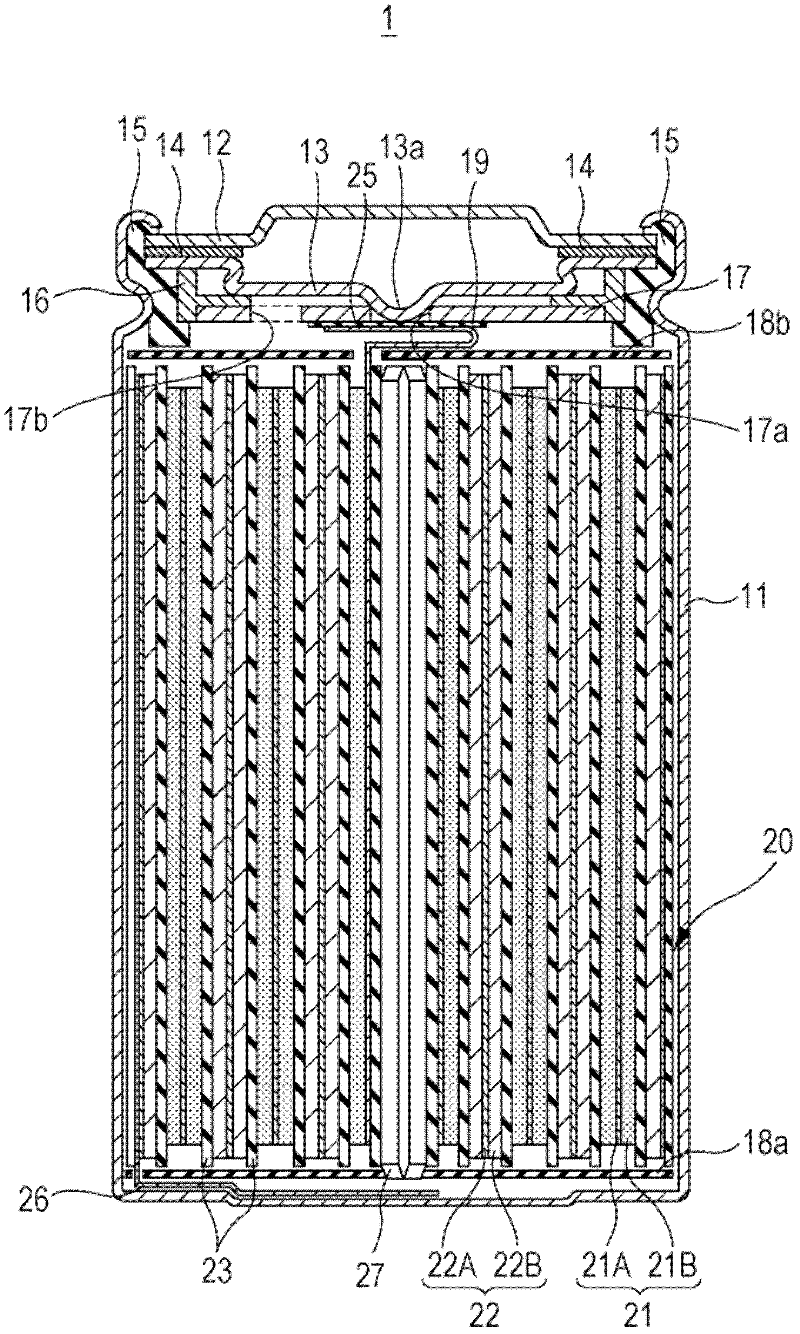

[0037] figure 1 A sectional view of a lithium ion secondary battery is shown, which is an example of the nonaqueous electrolyte battery 1 according to an embodiment of the present disclosure. The battery has a cylindrical shape and includes a wound electrode body 20 formed by winding a strip-shaped positive electrode 21 and a strip-shaped negative electrode 22 within an approximately hollow cylindrical battery case 11, Wherein the separator 23 is sandwiched between the positive electrode 21 and the negative electrode 22 together with a non-aqueous electrolyte solution (not shown). The battery case 11 is formed of, for example, nickel-plated steel, and one end of the battery case 11 is closed and the other end is opened. Inside the battery case 11, a pair of insulating plates 18a and 18b per...

no. 4 example

[0142] In this fourth embodiment, a nonaqueous electrolyte battery using a laminate in which a positive electrode and a negative electrode are laminated will be described.

[0143] 4-1. Structure of non-aqueous electrolyte battery

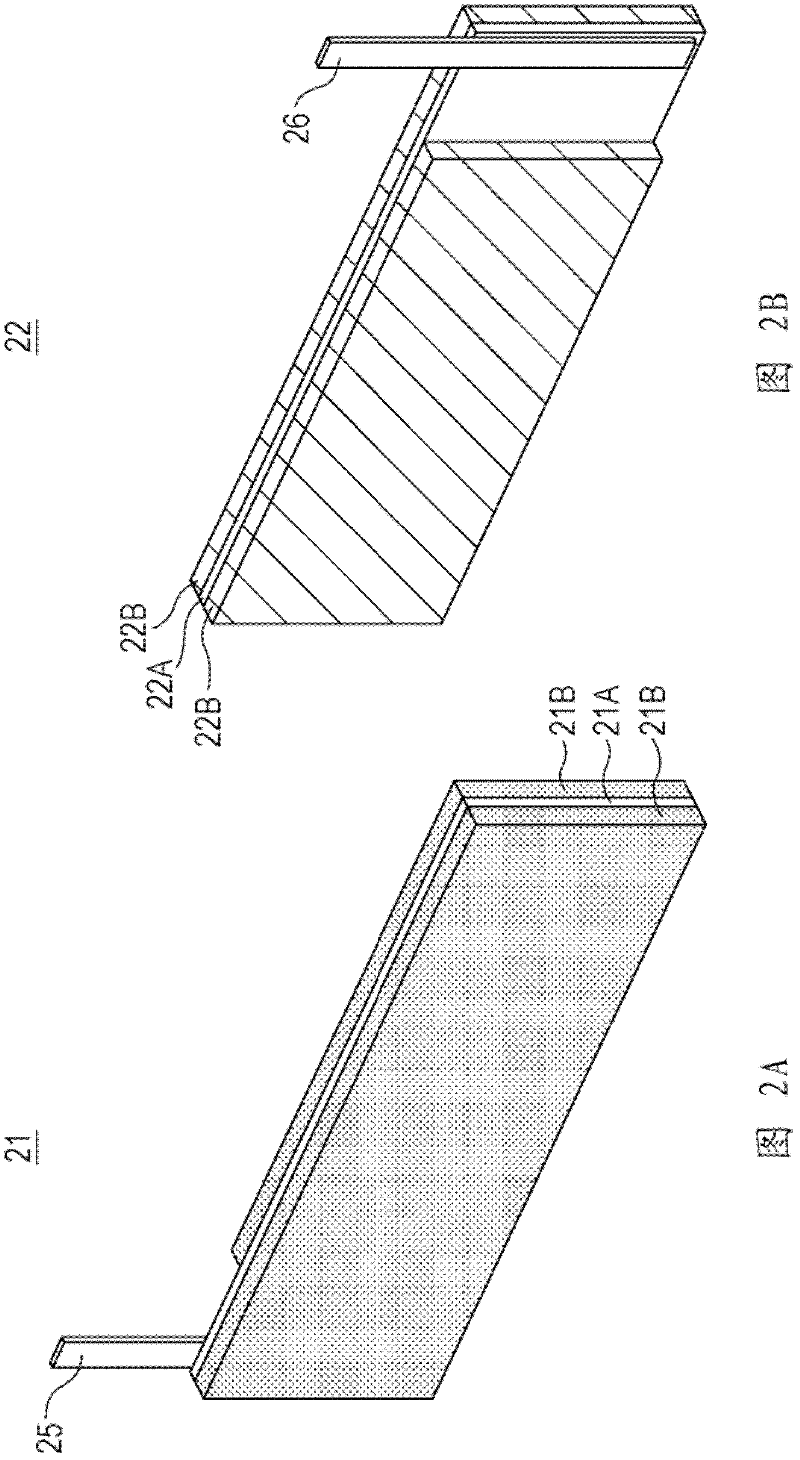

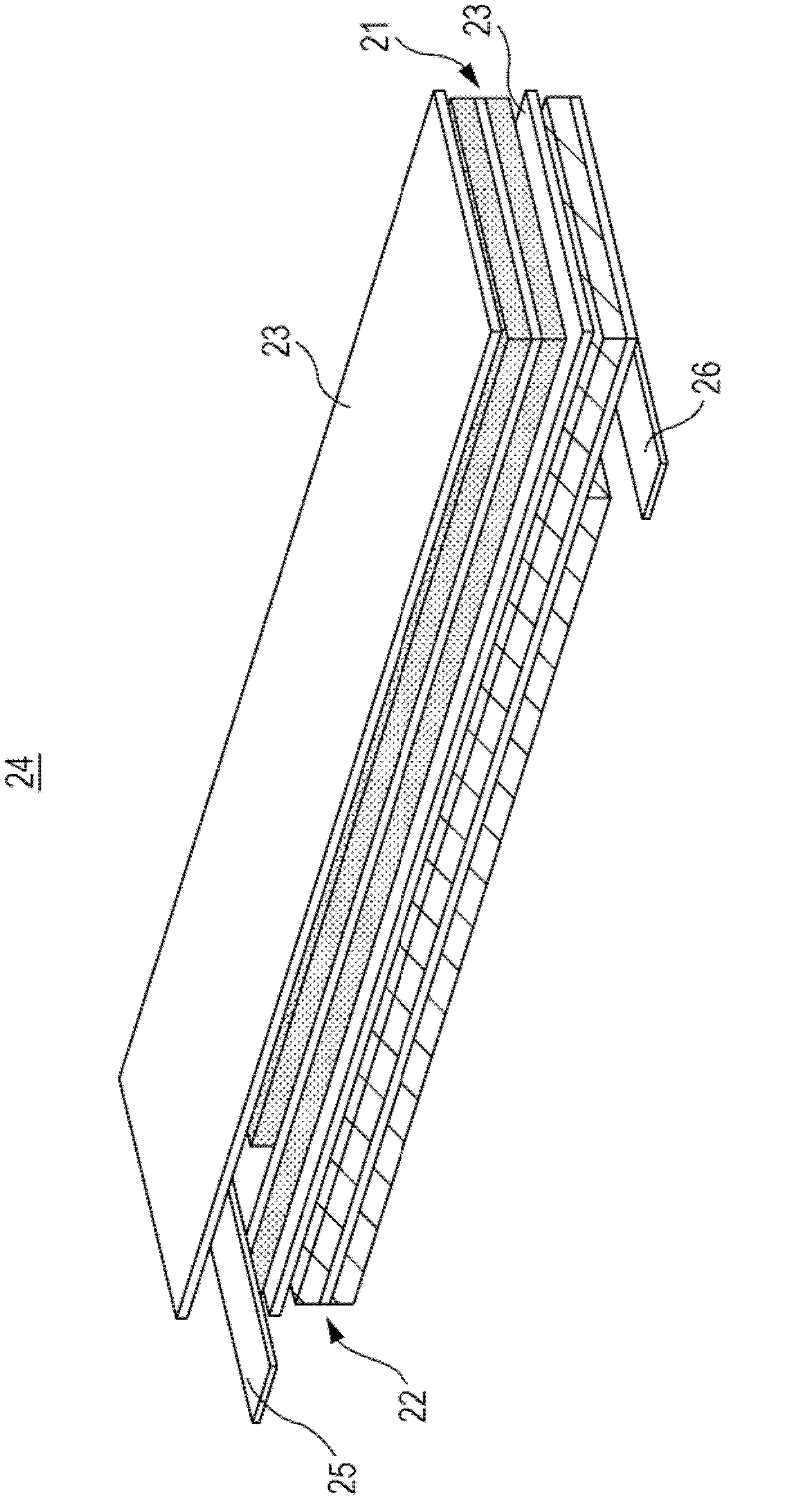

[0144] Figure 11A A perspective view showing the appearance of the nonaqueous electrolyte battery 30 according to the fourth embodiment is shown, Figure 11B An exploded perspective view showing the configuration of the nonaqueous electrolyte battery 30 . in addition, Figure 11C A perspective view showing the structure of the lower surface of the non-aqueous electrolyte battery 30, Figure 11D showing along Figure 11A Sectional view taken at midline XID-XID. In addition, in the following description, in the non-aqueous electrolyte battery 30, the part from which the positive electrode lead 32 and the negative electrode lead 33 protrude is called the top, and the part opposite to the top is called the bottom, between the top and the bottom. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com