Composite test apparatus of high-voltage direct current transmission converter valve

A high-voltage direct current transmission and synthetic test technology, which is applied in the direction of measuring devices, circuit breaker testing, and measuring electricity, can solve problems such as unsatisfactory equivalence, and achieve the effect of large selection, flexible methods, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

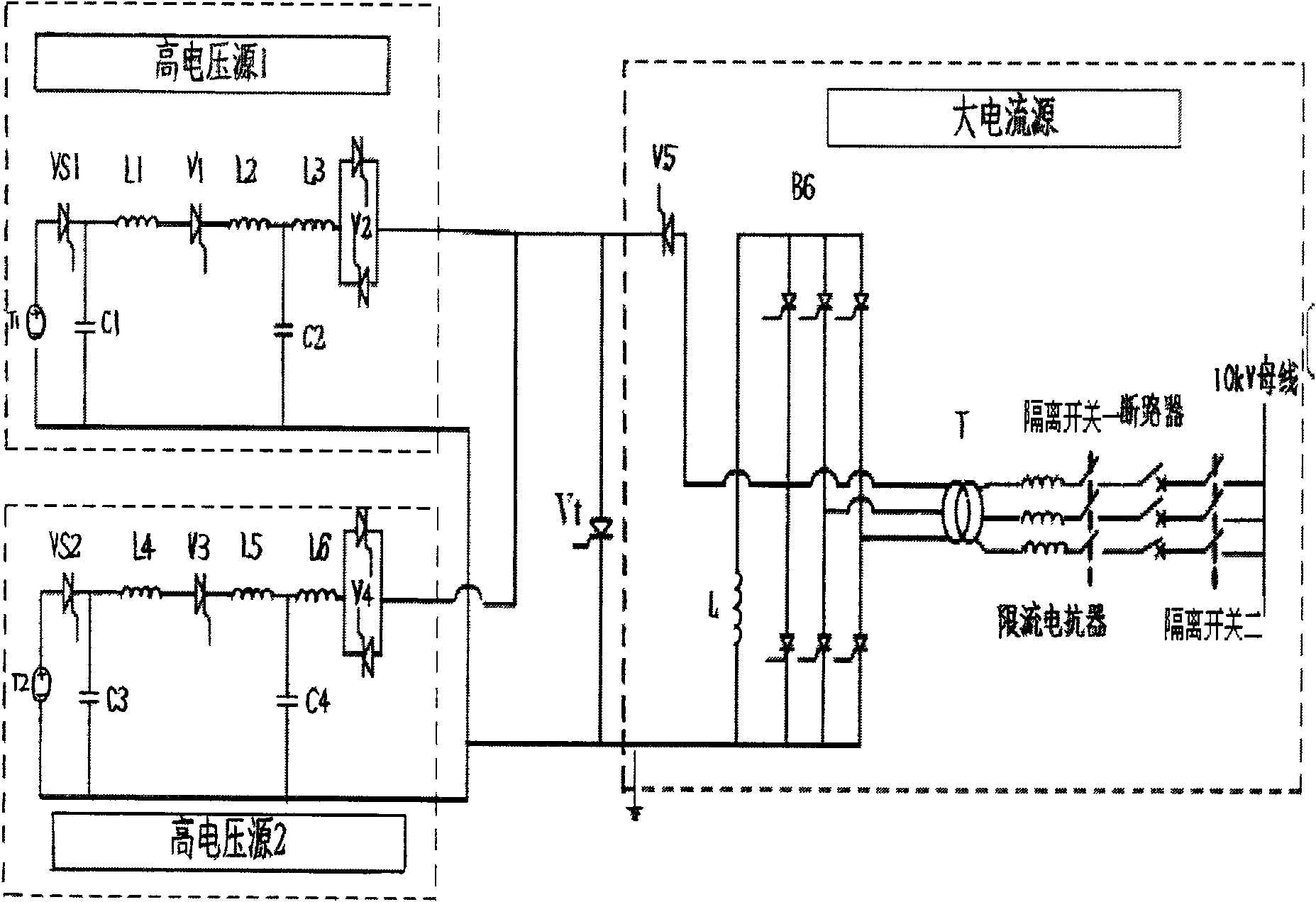

[0024] In the synthesis test of the high-voltage direct current transmission converter valve, the basic working principle of the present invention under the double-injection working mode:

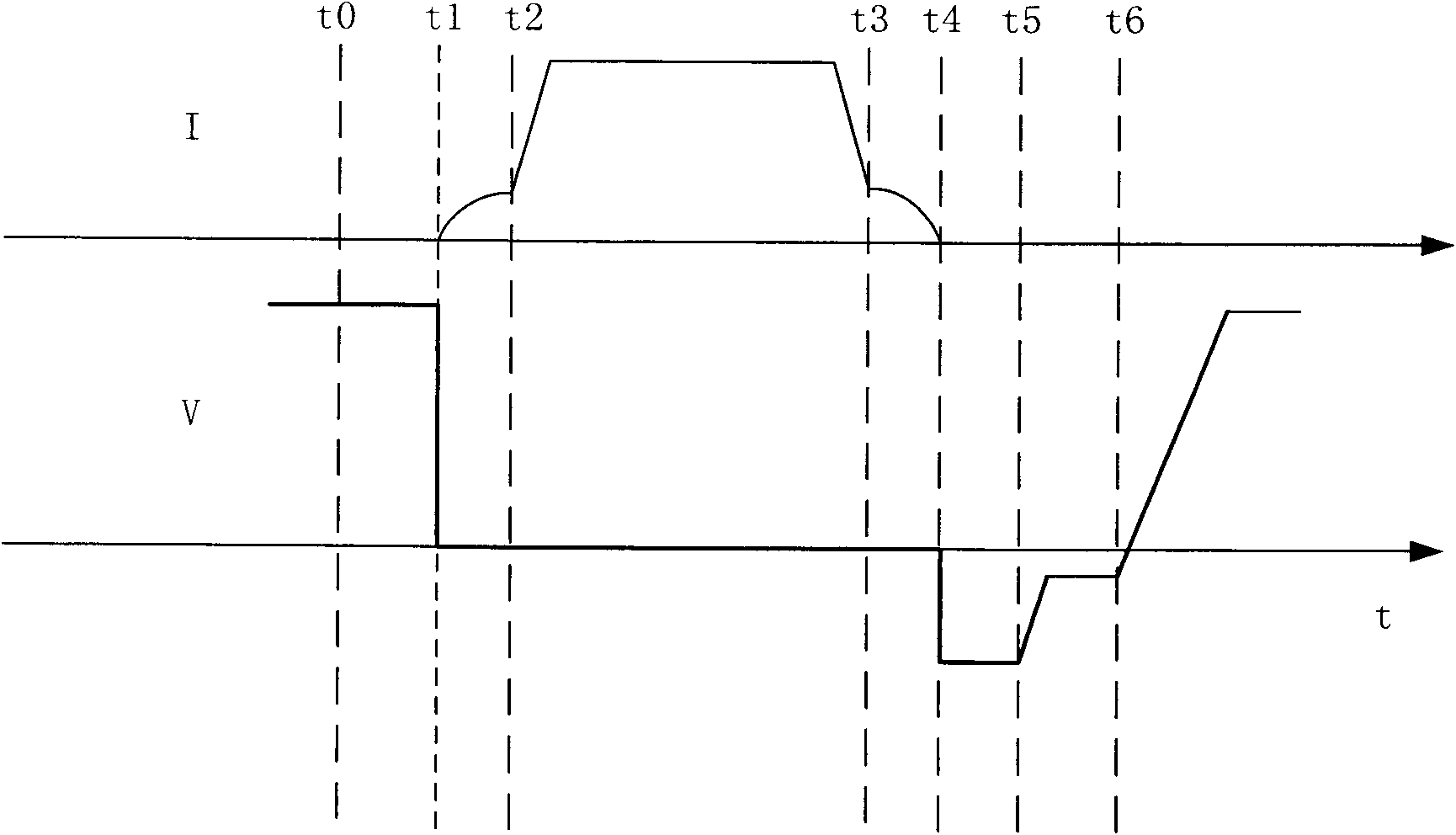

[0025] figure 2 It is the voltage and current cycle (20ms) waveform of the sample valve under the double injection mode of the synthetic test method.

[0026] At time t0, the sample valve Vt bears the positive high voltage generated by the high voltage source 1 circuit;

[0027] The test valve Vt and the auxiliary valve V2 are opened at time t1, and the resonant current in the high voltage source 1 flows through the test valve Vt;

[0028] Introduce the DC current in the DC large current source at time t2, and the test valve Vt bears the DC current during the conduction period;

[0029] At time t3, before the DC current goes out, the auxiliary valve V4 is opened, and the resonant current in the high voltage source 2 flows through the test valve Vt;

[0030] At time t4, the resonant curr...

Embodiment 2

[0034] In the synthesis test of the high-voltage direct current transmission converter valve, the basic working principle of the circuit of the present invention under the three-injection working mode:

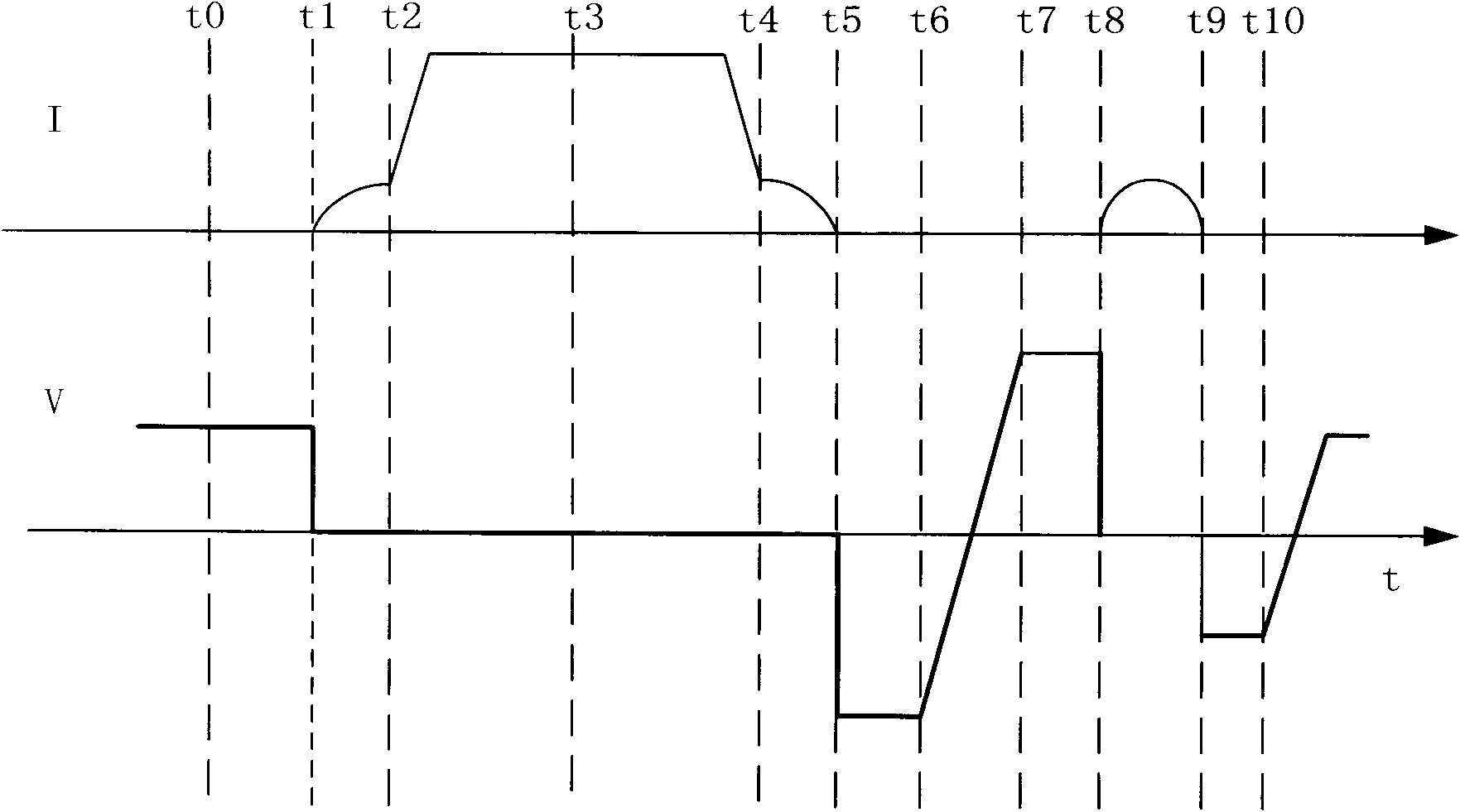

[0035] image 3 It is the voltage and current cycle (20ms) waveform of the sample valve under the synthetic test method three injection mode.

[0036] At time t0, the sample valve Vt bears the positive high voltage of the high voltage source 1;

[0037] The test valve Vt and the auxiliary valve V2 are opened at time t1, and the resonant current in the high voltage source 1 flows through the test valve Vt;

[0038] Introduce the DC current in the DC large current source 1 at time t2, and the test valve Vt bears the DC current during the conduction period;

[0039] Control the charging circuit T1, VS1, and C1 at time t3 to charge the high voltage source 1, so that its voltage returns to the voltage level at time t0;

[0040] At time t4, before the DC current goes out, the auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com