Two-dimensional chromatography multi-channel separating and purifying apparatus and method

A separation and purification, two-dimensional chromatography technology, applied in separation methods, chemical instruments and methods, measuring devices, etc., can solve the problems of large column packing consumption, less sample loading, long elution time, etc., and achieve high separation efficiency. , the effect of reducing consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

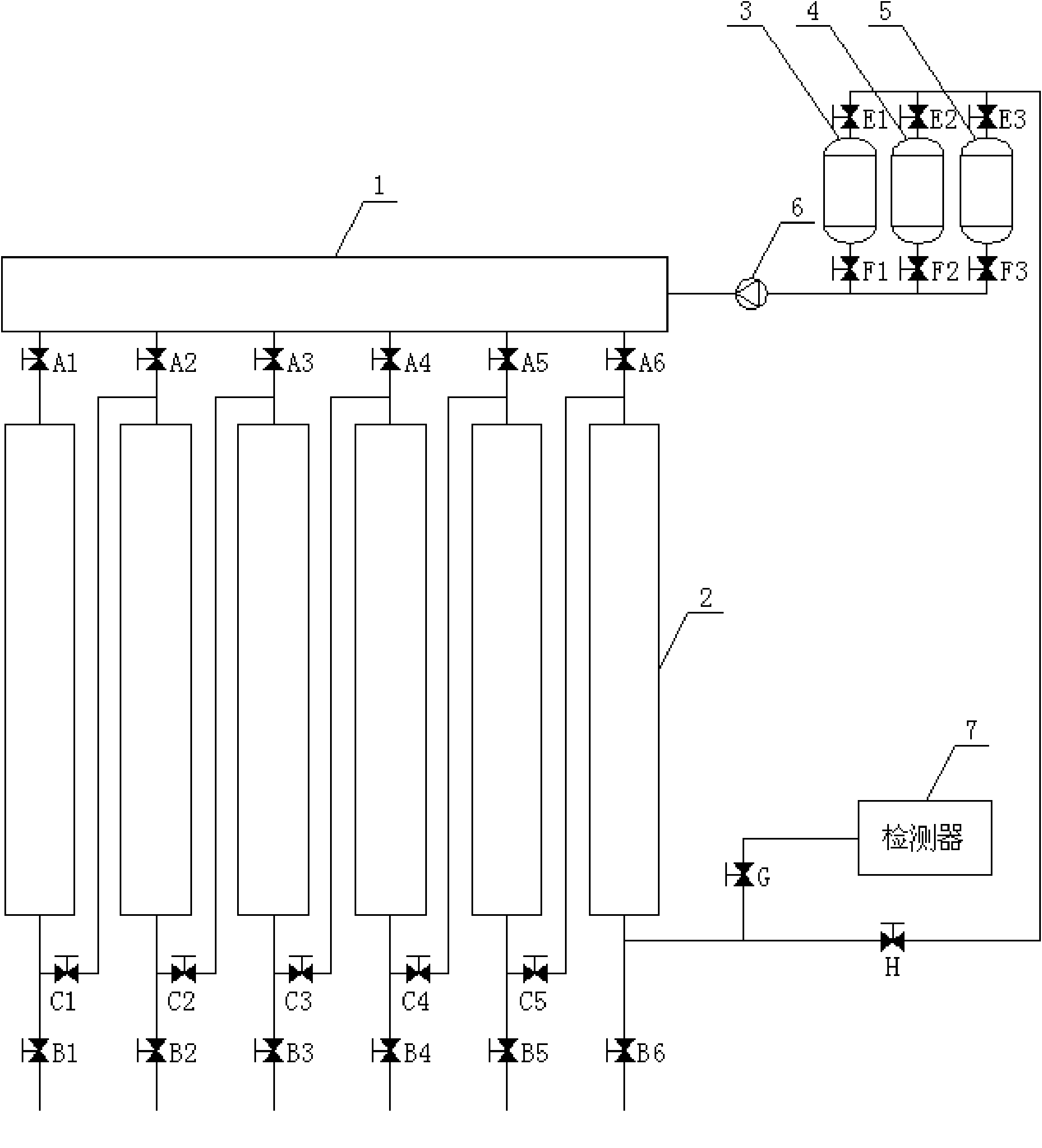

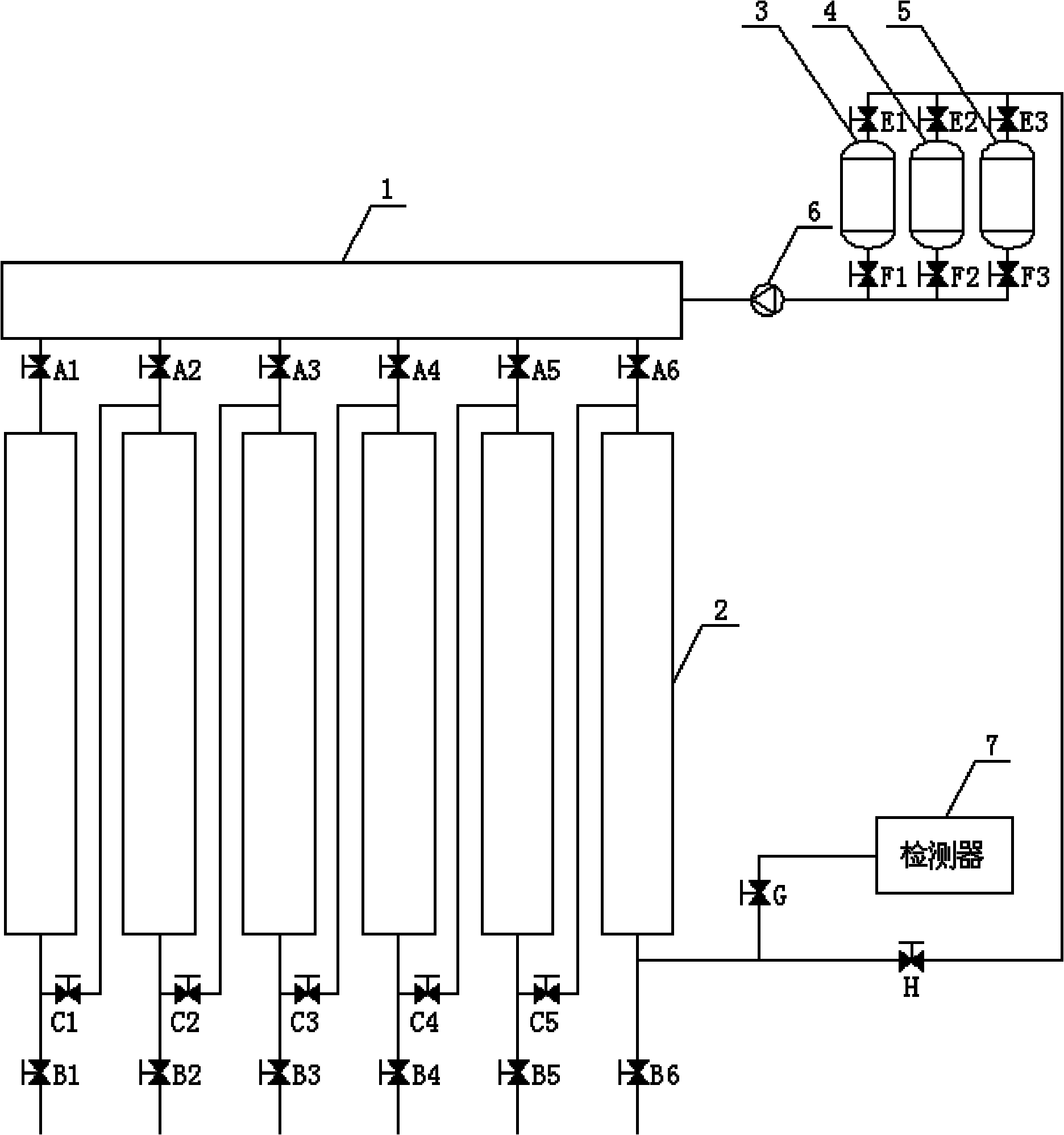

[0026] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the two-dimensional chromatographic multi-channel separation and purification device described in this embodiment includes a central distributor 1, a material tank 3, a mobile phase tank 4, a stationary phase tank 5, a pressure pump 6, a detector 7 and n Column 2,

[0027] The upper port of each chromatographic column 2 is connected with the central distributor 1 through a parallel valve, and the lower port of each chromatographic column 2 is provided with a discharge valve,

[0028] The lower port of the previous chromatographic column 2 also communicates with the upper port of the next chromatographic column 2 through a series tube, and a series valve is arranged on the series tube, so that n chromatographic columns 2 are connected end to end, and the last chromatographic column 2 The output of the lower port is sent to the detector 7 through the detection valve, and the lo...

specific Embodiment approach 2

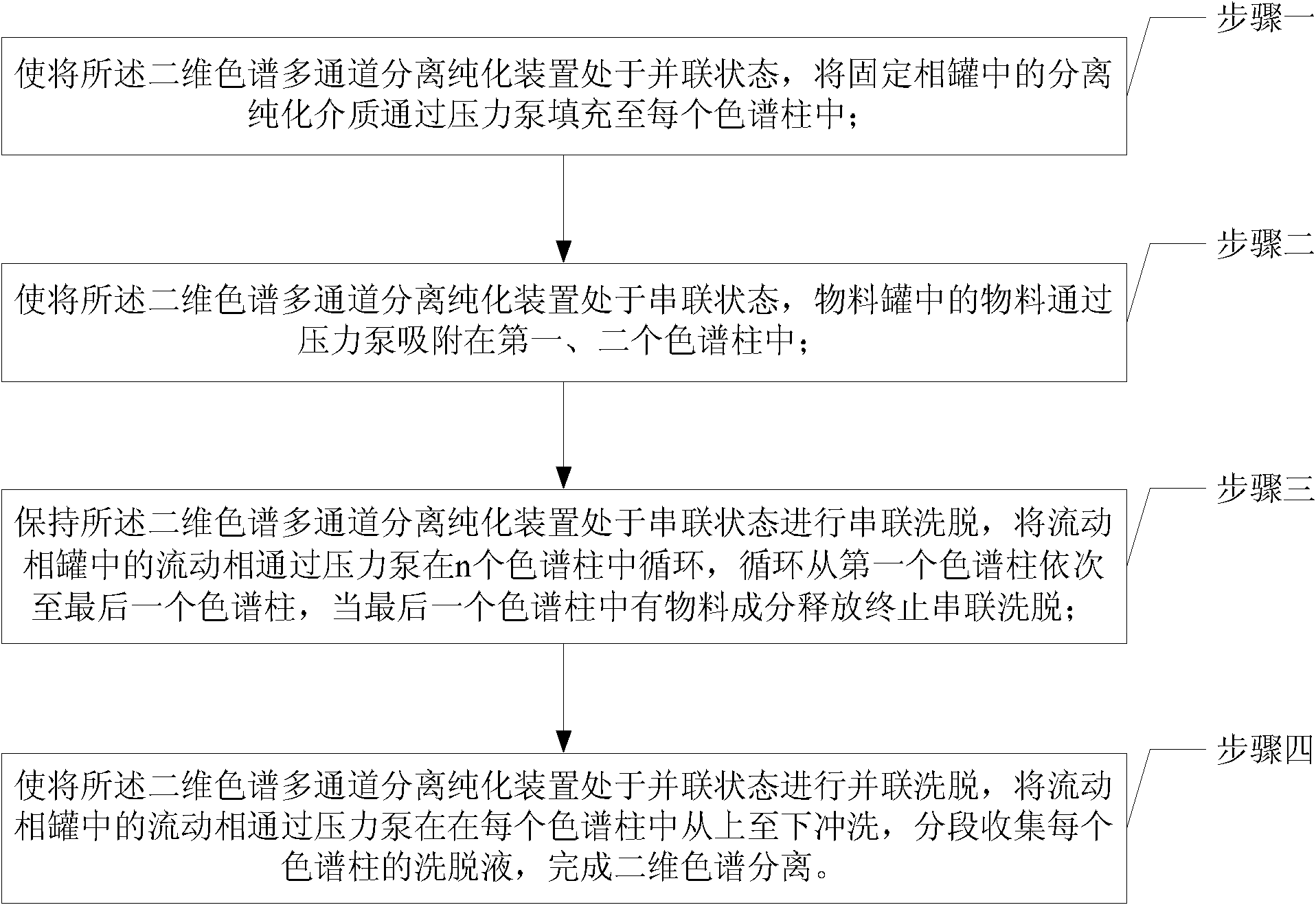

[0039] Specific implementation mode two: the following combination figure 2 To illustrate this embodiment, the two-dimensional chromatographic multi-channel separation and purification method based on the two-dimensional chromatographic multi-channel separation and purification device described in the first embodiment, the method includes the following steps:

[0040] Step 1, making a plurality of chromatographic columns 2 in the two-dimensional chromatographic multi-channel separation and purification device in parallel mode, and filling the separation and purification medium in the stationary phase tank 5 into each chromatographic column 2 through a pressure pump 6;

[0041] Step 2, making the plurality of chromatographic columns 2 in the two-dimensional chromatographic multi-channel separation and purification device be in a series mode, and the material in the material tank 3 is adsorbed in the first and second chromatographic columns 2 by the pressure pump 6;

[0042] St...

specific Embodiment approach 3

[0045]Specific embodiment three: this embodiment will further explain embodiment two, and the valves in the open state in step one are: the parallel valve provided at the upper port of each chromatographic column 2, the discharge valve provided at the lower port of each chromatographic column 2 and A discharge valve arranged at the lower end of the stationary phase tank 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com