Piston water supply type atomization gas generator

A technology of atomizing gas and generator, which is applied to liquid spraying device, spraying device, etc., can solve the problems of small output of mist, limited water supply capacity, waste of power resources, etc., and achieves good atomization effect, sufficient water supply and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

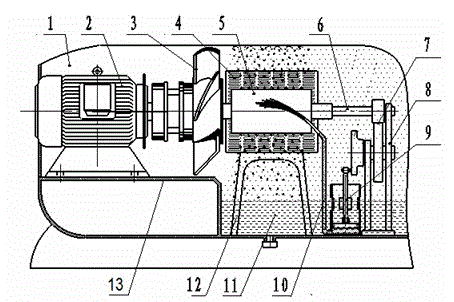

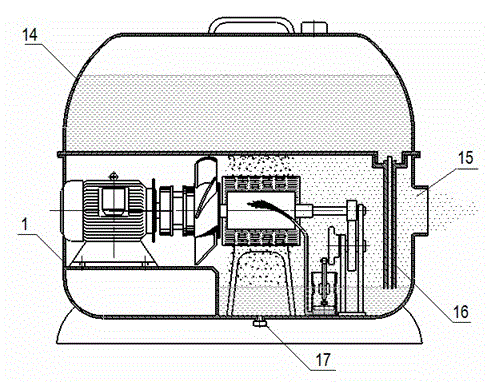

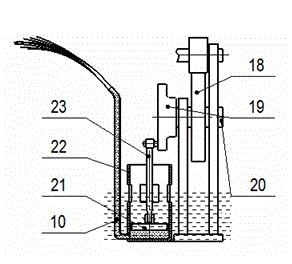

[0021] Example 1: as Figure 1-3 As shown, the piston water-supply type atomizing gas generator includes a device body 1, a motor 2, a fan 3, a cylindrical net 4, a small-hole cylindrical bucket 5, a rotating shaft 6, a reduction transmission device 7, a reduction transmission bracket 8, and a piston water supply Device 9, water spray pipe 10, cylindrical net support 12, motor support 13; fan 3 and small hole cylindrical bucket 5 are fixed on the rotating shaft 6, cylindrical net 4 is set outside the small hole cylindrical bucket 5; the bottom of the device body is for water supply Pool 11, cylindrical net support 12 is placed at the bottom of device body 1, cylindrical net 4 is supported by cylindrical net support 12, the lower end of water spray pipe 10 is connected to piston water supply device 9 outlets, and the upper port stretches in cylindrical net 4; The motor output shaft is connected, and the other end is connected to the piston of the piston water supply device 9 th...

Embodiment 2

[0023] Example 2: as Figure 1-3 As shown, the structure of the piston water-supply atomizing gas generator is the same as that of Embodiment 1. There are 2 square water inlet holes evenly opened on the peripheral wall of the upper part of the piston cylinder 22, and the size of the square water inlet holes is 6×6 ×6mm, the diameter of the small holes on the barrel wall of the small hole cylinder 5 is 1.5mm, the hole distance is 3mm, and the transmission ratio of the gear reduction mechanism is 1:5.

Embodiment 3

[0024] Example 3: as Figure 1-3 As shown, the structure of the piston water-supply type atomizing gas generator is the same as that of Embodiment 1, and there are 6 small square water inlet holes uniformly opened on the peripheral wall of the middle and upper part of the piston cylinder 22, and the size of the square water inlet holes is 4×4 ×4mm, the diameter of the small holes on the barrel wall of the small hole cylinder 5 is 1mm, the hole distance is 2mm, and the transmission ratio of the gear reduction mechanism is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com