Device for automatic welding and random positioning and automatic clamping and resetting

A technology of automatic clamping and resetting device, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as low manufacturing cost, achieve high production efficiency, accurate positioning, and prevent and reduce welding stress and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

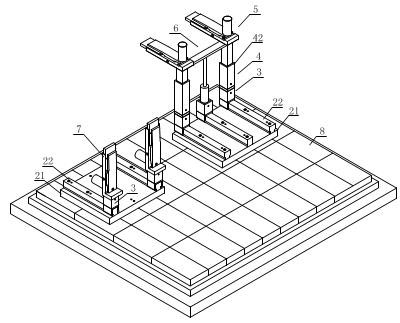

[0027] Below in conjunction with accompanying drawing, describe the specific embodiment of the present invention in detail: Please refer to Figure 1 to Figure 9 .

[0028] The present invention is an automatic welding random positioning and automatic clamping reset device, such as figure 1 As mentioned, the device includes: a horizontal fixed workpiece frame, a vertical fixed workpiece frame and a magnet fixed platform 8 .

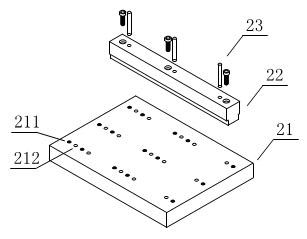

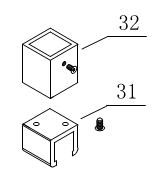

[0029] The horizontal fixed workpiece frame structure is composed of base group, slider group 3, connector group 4, horizontal clamp group 5 and reset group 6. The base group is composed of a bottom plate 21 and three guide rails 22. The slider group 3 has three The groups are respectively fixedly socketed on the three guide rails 22, and there are two groups of connector groups 4, which are respectively fixed on the slider groups 3 at the two ends of the three sliders forming a linear arrangement, and a group of sliders is fixed on the middle sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com