Simple precision displacement platform

A precision displacement and simple technology, applied in the field of precision engineering, can solve the problems of slow response speed, contradiction between large stroke and high precision, low stiffness, etc., and achieve the effect of improving stiffness, reducing transmission links, and improving anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

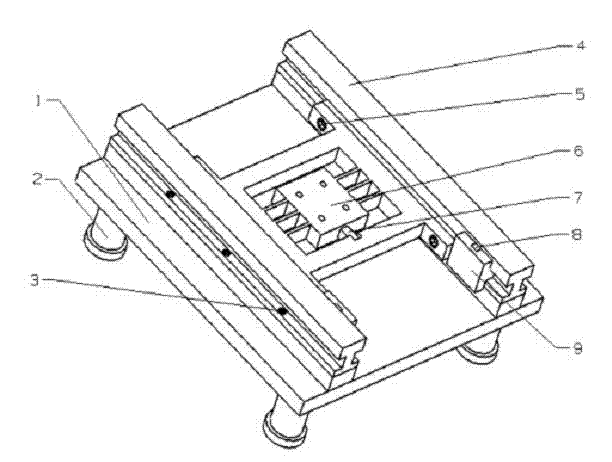

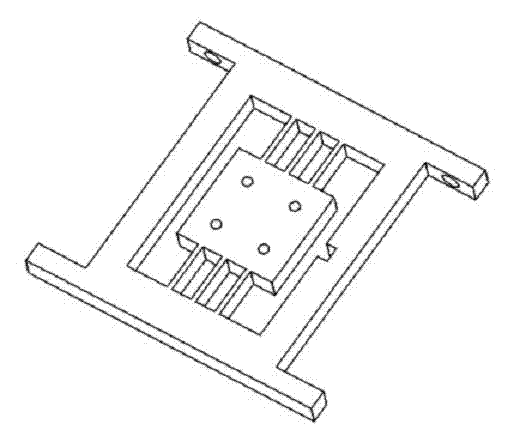

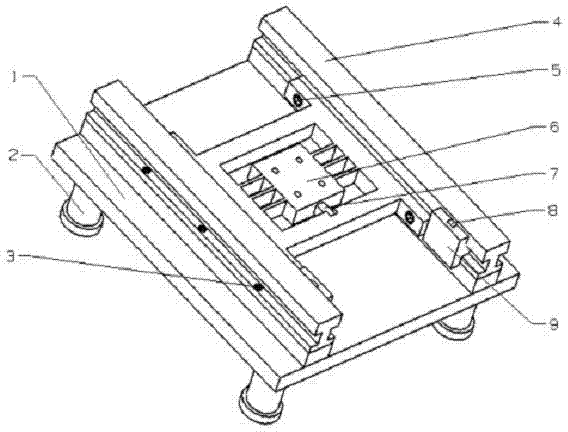

[0013] Invented simple precision translation stage such as figure 1 As shown, including base 1, vibration isolator 2, fixed hexagon socket screw 3, linear guide rail 4, hexagon socket set screw 5, micro-motion table 6, piezoelectric ceramic driver 7, linear grating scale 8, linear motor 9 .

[0014] The base 1 is used as the carrier of the entire stage, and plays a role of installation support for the entire component. The vibration isolator 2 installed at the bottom of the base 1 plays a role of vibration isolation and can effectively eliminate the impact of external factors, especially external vibration, on the performance of the entire platform.

[0015] The linear guide rail 4 is fastened on the base 1 by fixing the hexagon socket head cap screw 3, and acts as a guiding part for large stroke movement. A linear motor 9 is installed on the linear guide rail 4, and is connected with the micro-motion platform 6 through the hexagon socket set screw 5. The hexagon socket hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com