Construction site thin and long single sheet transfer process and equipment

A construction site and monolithic technology, which is applied to the field of reverse transportation technology and equipment of the slender structure monolithic construction site, can solve the problems of destroying the characteristics of the base material, affecting the construction period, increasing the difficulty of operation, etc., so as to utilize the space resources of the site and improve the coating The effect of loading efficiency and improving film output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The specification of the delivery deck piece is 35m long * 5.4m wide.

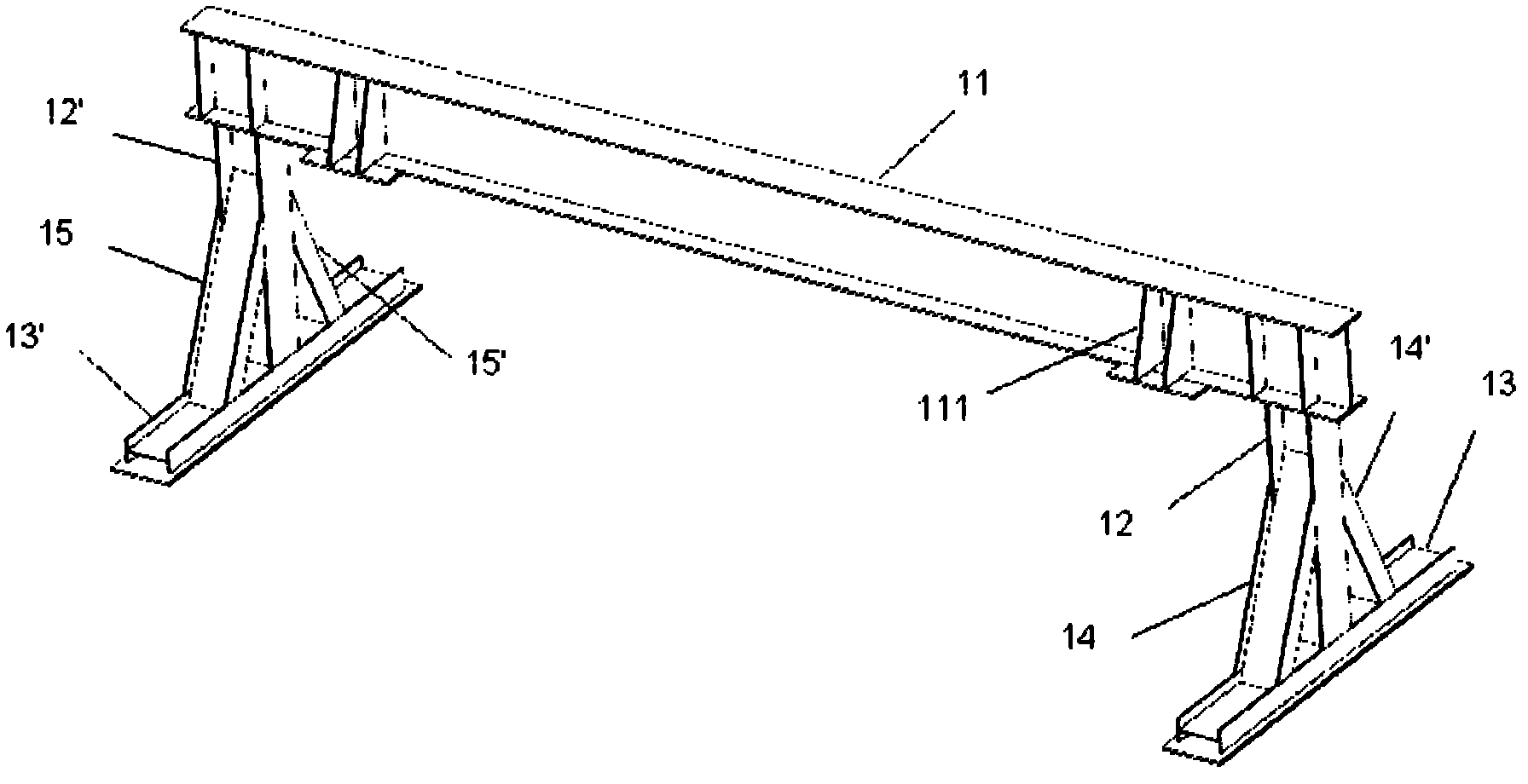

[0034] Step 1: Prefabricate 2 door-shaped brackets 1 in advance according to the specification (35m long * 5.4m wide) of the deck piece to be transported (such as figure 1 shown), the size of the door-shaped bracket is 8m long * 2.7m wide * 2.4m high, and the base length is 2.7m;

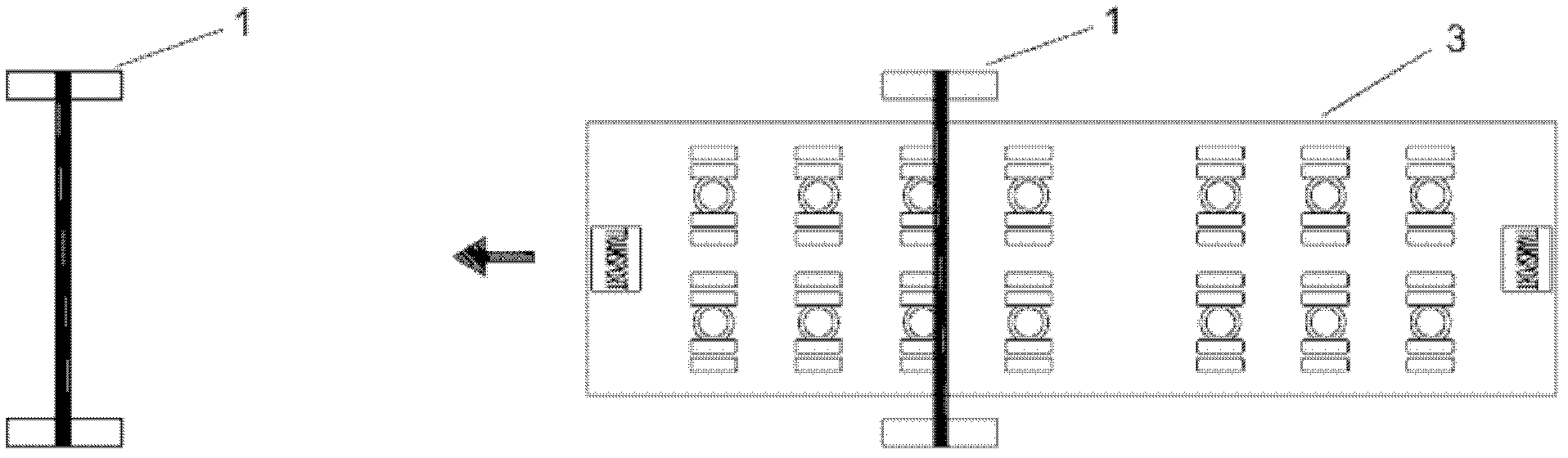

[0035] Step 2: First place the two door-shaped brackets 1 with a forklift at a distance of 19m, then lower the height of the flatbed truck 3 so that the flatbed truck 3 enters the door-shaped bracket 1 and jacks up the door-shaped bracket 1, and then transports the door-shaped bracket 1 to Next to the prefabricated deck piece 2; (such as figure 2 shown).

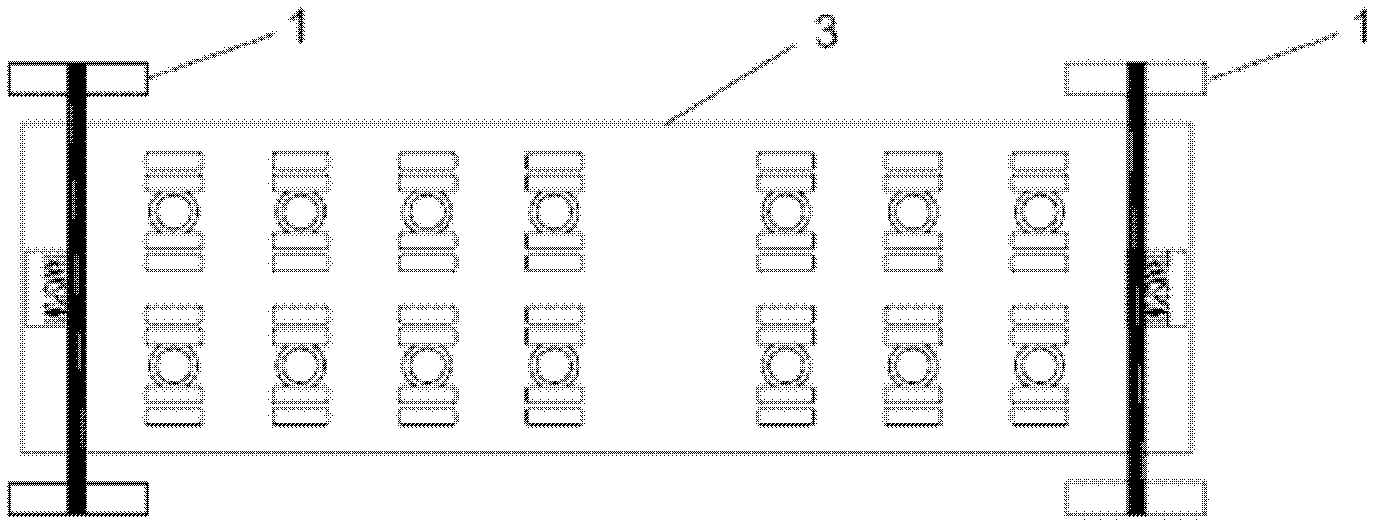

[0036] Step 3: hoist the deck piece 2 to the top of the two portal brackets 1, then lift the portal bracket 1 and the deck piece 2 by the flatbed truck 3, and transport them to a designated place, such as a spraying workshop; image 3 , Figure 4 , Figure 6 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com