Choking cavitator for treating organic sewage

A technology of organic sewage and cavitation, which is applied in the direction of oxidation water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of low inlet pressure and cavitation not effectively collapsed, etc. Achieve the effect of high energy utilization rate, simple structure and strong oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

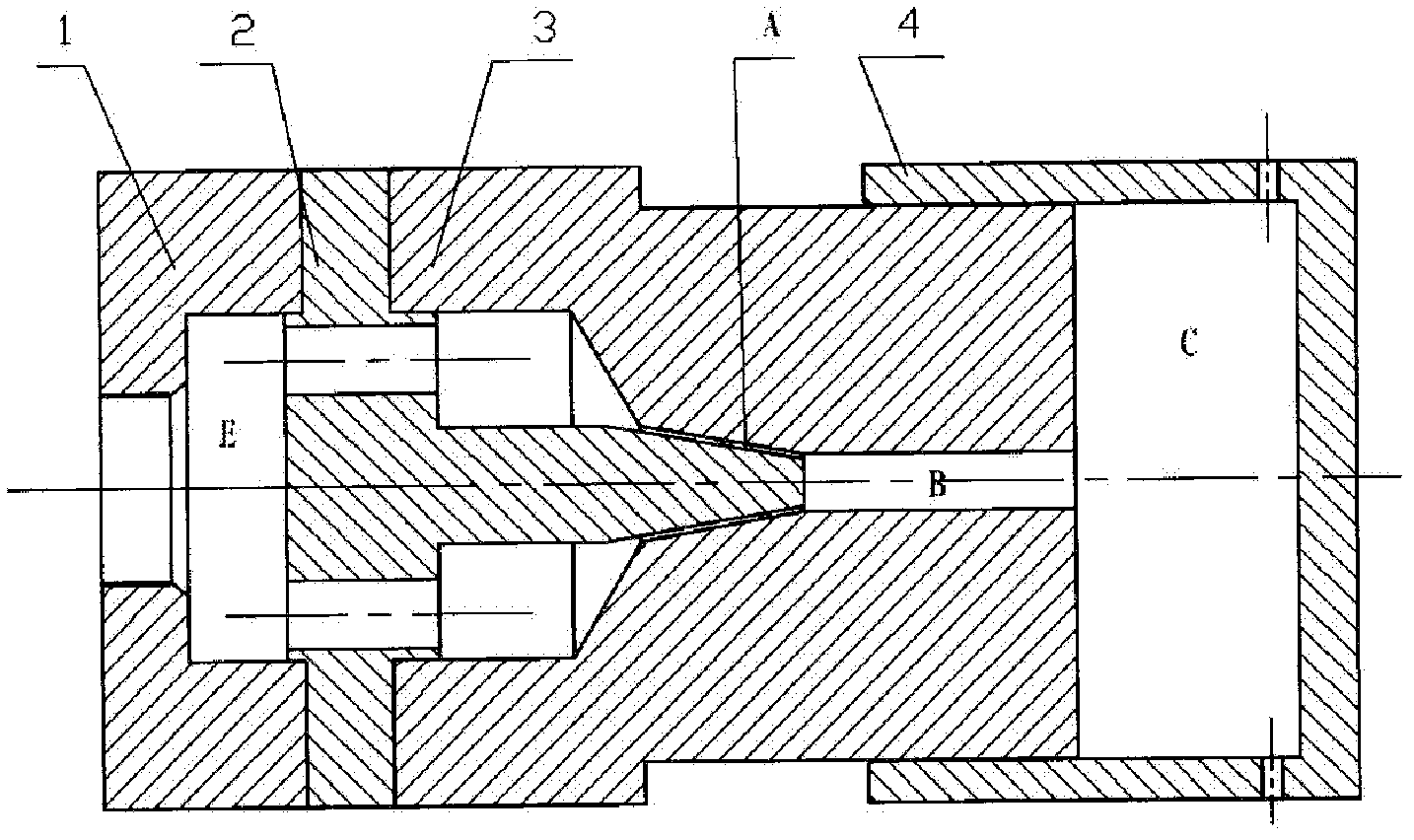

[0034] The embodiment of the present invention is illustrated by using three different cavitation generators to conduct a comparative test of phenol degradation ability under the same experimental conditions. The clogged cavitator is the present invention; the oscillating cavity cavitation nozzle is a nozzle with an oscillating cavity, and its outlet has a conical expansion section with a cone angle of 30°; the ordinary nozzle is an ordinary nozzle with a contraction angle of 60°.

[0035] 1) Implementation parameters of the present invention

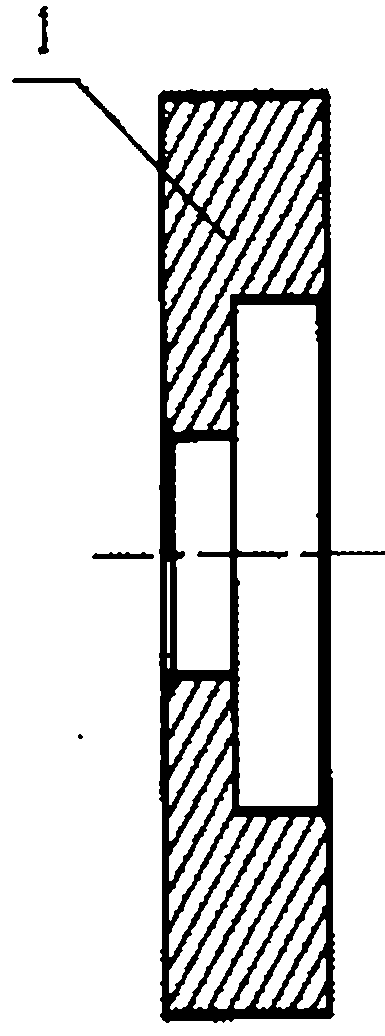

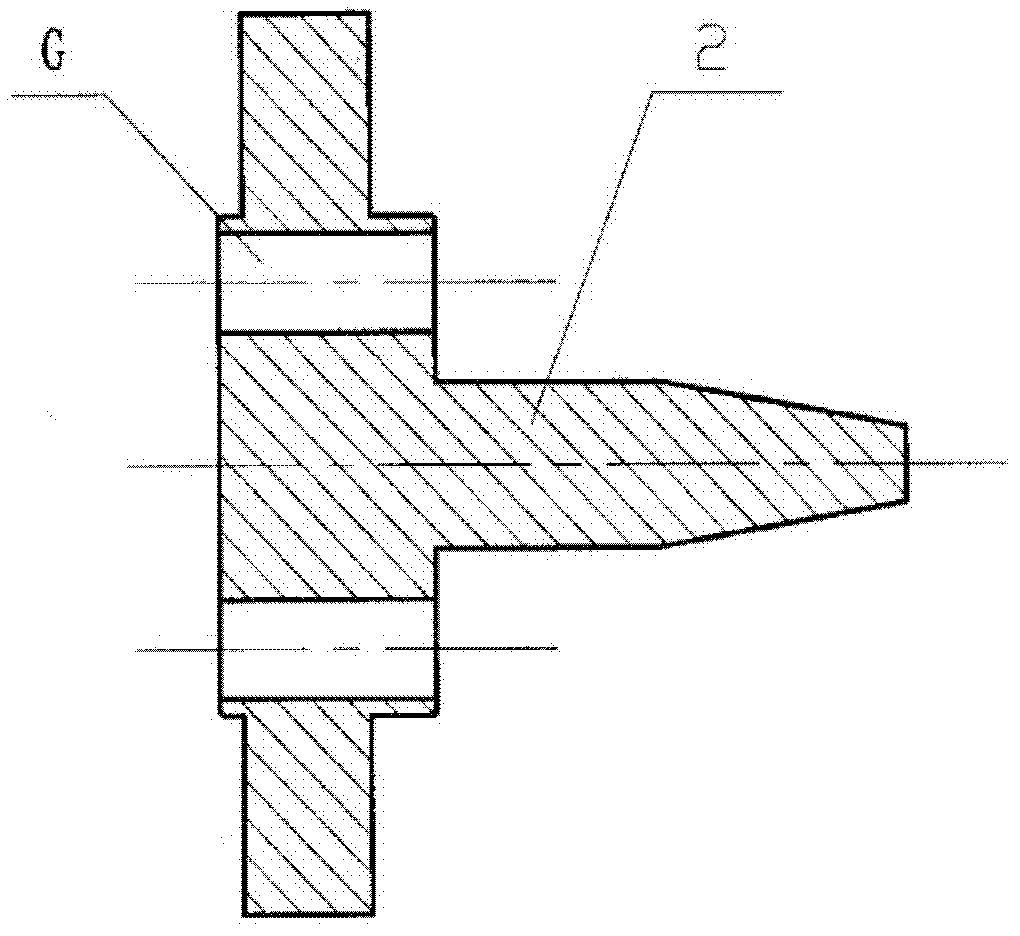

[0036] like figure 1 , The water inlet joint 1, the nozzle body 2 and the blocking body 3 are connected with bolts, the blocking body 3 is connected with the back pressure cover 4 with threads, and the water inlet joint 1 is connected with the external water supply pipe with threads. Each connection part adopts the corresponding sealing form. The equivalent diameter of the annular nozzle is 2.8mm, the width of the annular gap is 0.2mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com