Spontaneous heating bag and production method thereof

A self-heating and heat-generating bag technology, applied in the field of heat preservation, can solve problems such as serious bloody smell, and achieve the effect of facilitating emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0097] A kind of self-heating bag, the raw material in it comprises the self-heating material that can generate heat by itself through chemical reaction, and the spice that can distribute plant fragrance is also included in the raw material, and described spice is the petal of dried lavender; The petal of lavender accounts for the total weight of raw material 25%. The self-heating material includes by weight: iron powder, 40 parts; activated carbon, 8 parts; vermiculite, 10 parts; sodium chloride, 1 part; water-absorbing resin, 1 part; water, 15 parts.

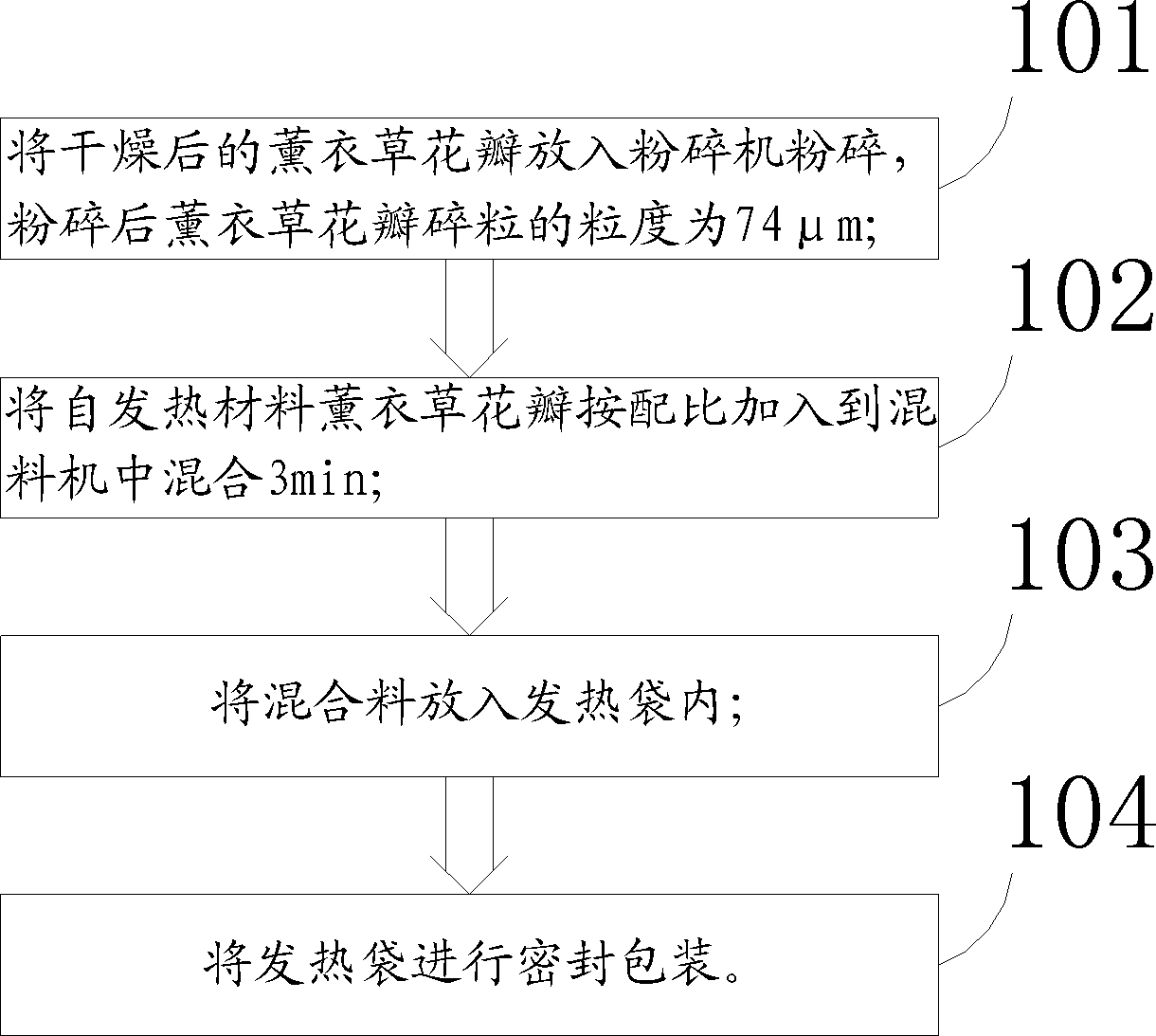

[0098] A kind of production method of self-heating bag, such as figure 1 shown, including the following steps:

[0099] 101) Put the dried lavender petals into a pulverizer for crushing, and the particle size of the crushed lavender petals is 74 μm;

[0100] 102) Add the self-heating material and lavender petals into the blender according to the ratio and mix for 3 minutes;

[0101] 103) Put the mixture into the heating bag...

specific Embodiment 2

[0103] A self-heating bag, the raw material inside it includes a self-heating material that can heat itself through a chemical reaction, and the raw material also includes spices that can emit plant fragrance, and the spices are dried rose petals; rose petals account for 10% of the total weight of raw materials. 1%; the self-heating material includes by weight: iron powder, 60 parts; activated carbon, 18 parts; vermiculite, 25 parts; sodium chloride, 5 parts; water-absorbing resin, 5 parts; water, 30 parts.

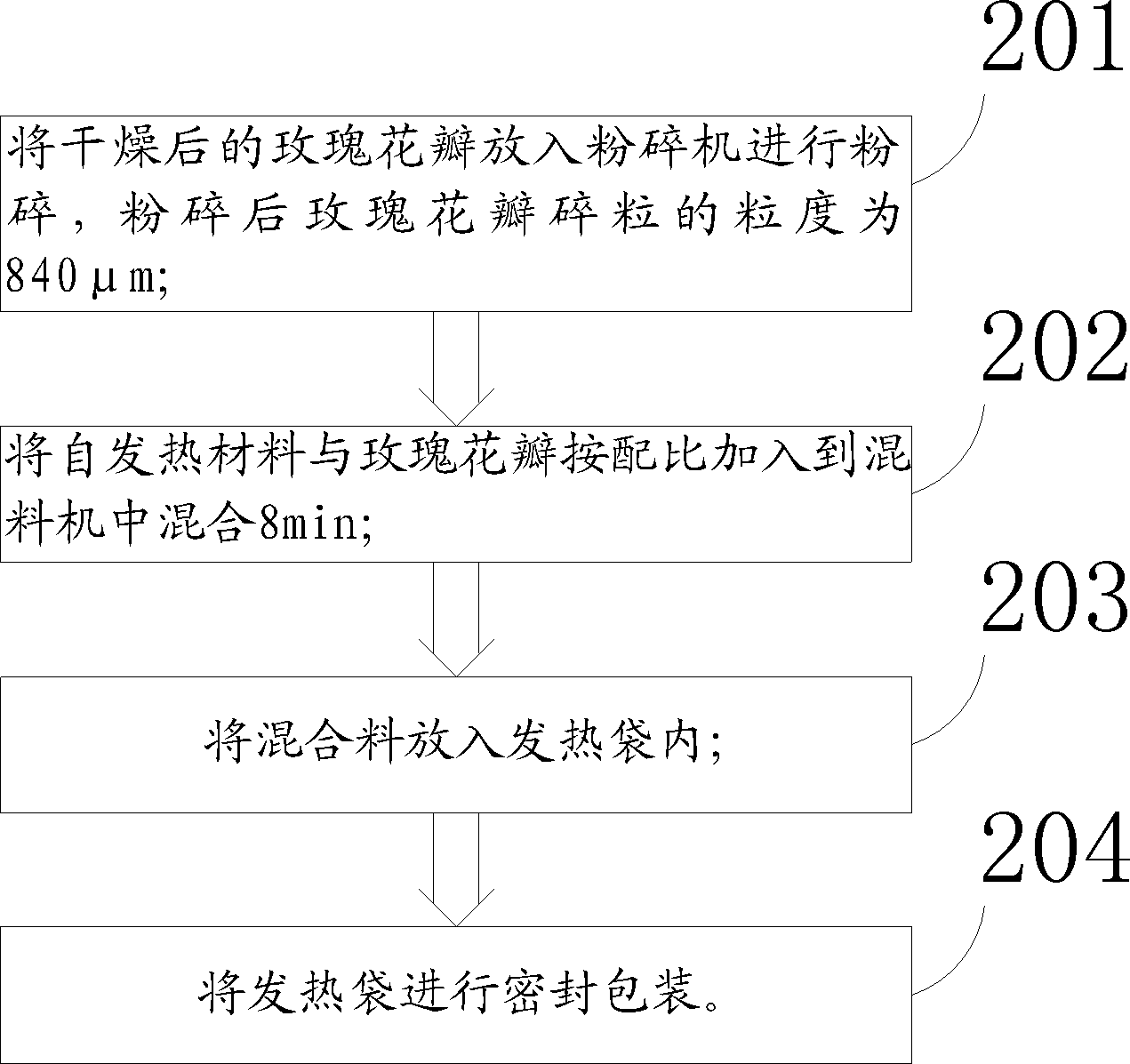

[0104] A kind of production method of self-heating bag, such as figure 2 shown, including the following steps:

[0105] 201) Put the dried rose petals into a pulverizer for crushing, and the particle size of the crushed rose petals is 840 μm;

[0106] 202) Add the self-heating material and rose petals into the mixer according to the proportion and mix for 8 minutes;

[0107] 203) Put the mixture into the heating bag;

[0108] 204) Sealing and packaging the heating bag...

specific Embodiment 3

[0109] A self-heating bag, the raw material in it includes a self-heating material that can heat itself through chemical reaction, and the spice that can emit plant aroma, and the spice is tea tree essential oil; the tea tree essential oil accounts for 0.01% of the total weight of the raw material. The self-heating material includes by weight: iron powder, 40 parts; activated carbon, 18 parts; vermiculite, 10 parts; sodium chloride, 5 parts; water-absorbing resin, 1 part; water, 30 parts.

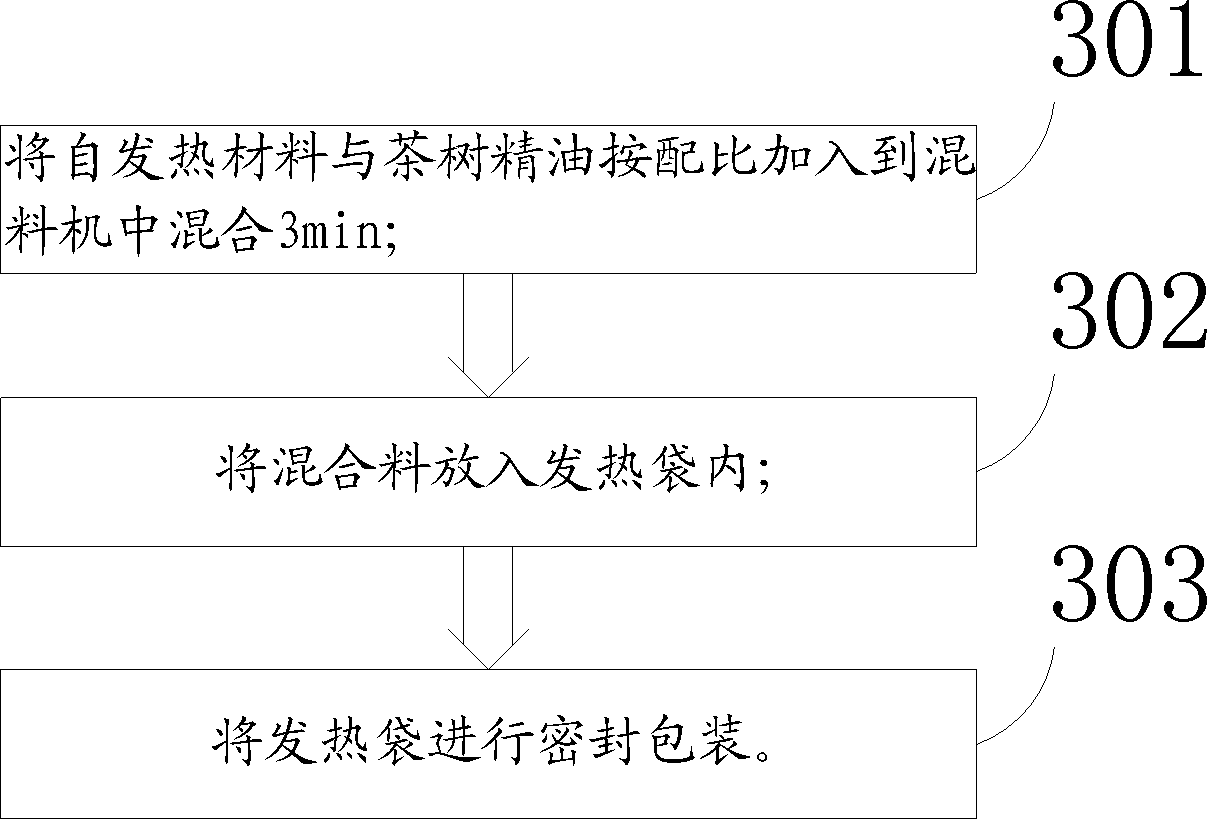

[0110] A kind of production method of self-heating bag, such as image 3 shown, including the following steps:

[0111] 301) Add the self-heating material and tea tree essential oil into the mixer according to the proportion and mix for 3 minutes;

[0112] 302) Put the mixture into the heating bag;

[0113] 303) Sealing and packaging the heating bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com