Steel for lower plate of cargo oil tank of tanker

A technology of cargo oil tank and bottom plate, applied in the field of ship plate steel, can solve the problems of bulky cargo oil tank, long construction time and high maintenance cost, and achieve the effect of reducing maintenance cost, inhibiting local corrosion and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (simulated cargo oil tank pitting method)

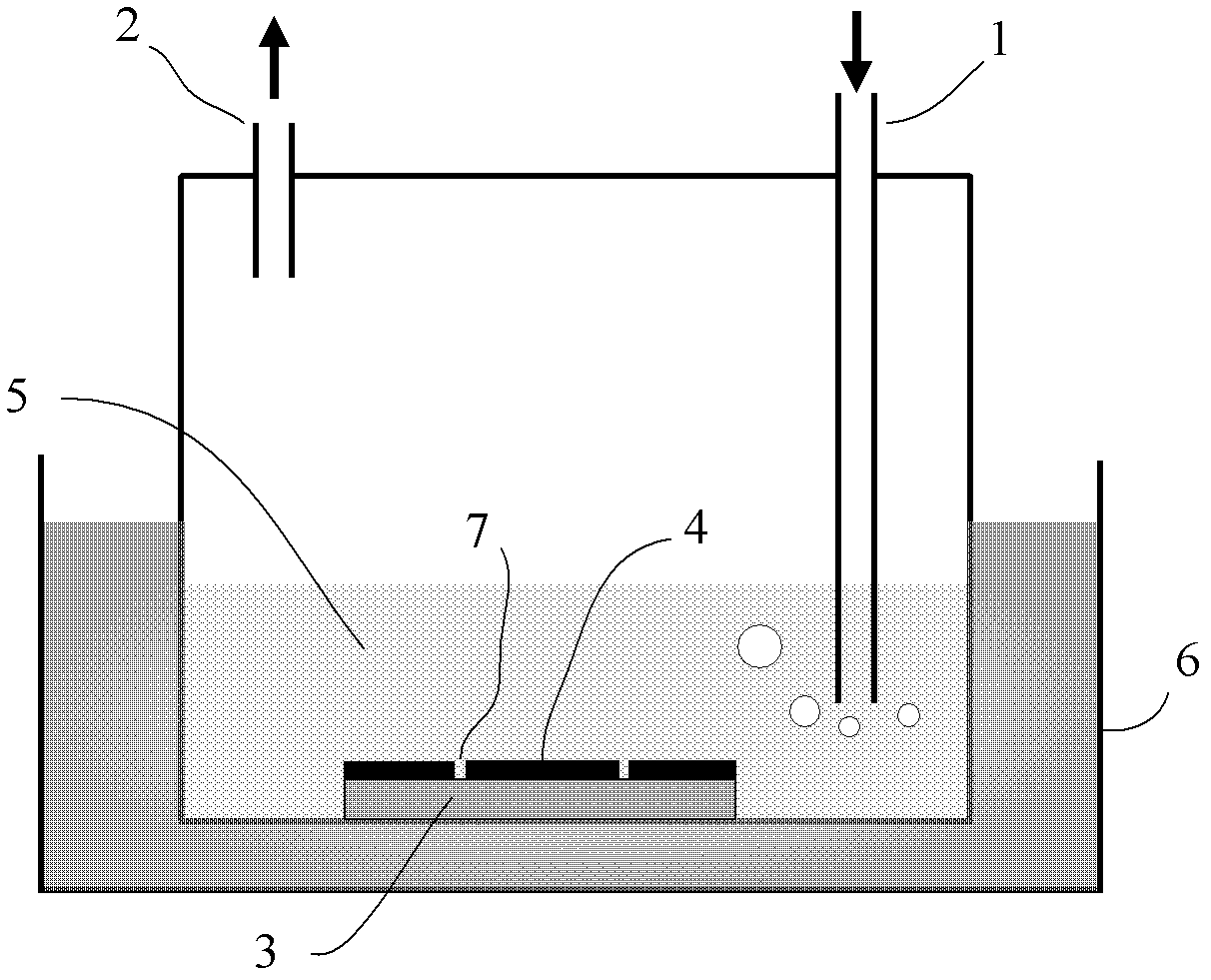

[0036] figure 1 In order to simulate the pitting corrosion of the bottom plate of the cargo oil tank. For each of the above-mentioned 40mm (length) × 40mm (width) × 15mm (thickness) square samples of 3 pieces, the test surface is polished to 600#, and cleaned with alcohol and acetone. Carry out a test on a 40mm×40mm surface of the sample, first coat the non-test surface with epoxy resin, and only coat the oil sludge at the bottom of the cargo oil tank of the actual oil tanker evenly on the test surface, and leave 4 small holes of φ2mm bare (see figure 1 7 positions) to simulate the starting point of localized corrosion.

[0037] During the test, the sample is figure 1 The method in is placed at the bottom of the reaction vessel, a certain amount of 10% NaCl aqueous solution is injected into the vessel 5, and the water temperature in the constant temperature water bath 6 is set to 40°C, and the following two ga...

Embodiment 2

[0038] Embodiment 2 (laboratory hanging piece)

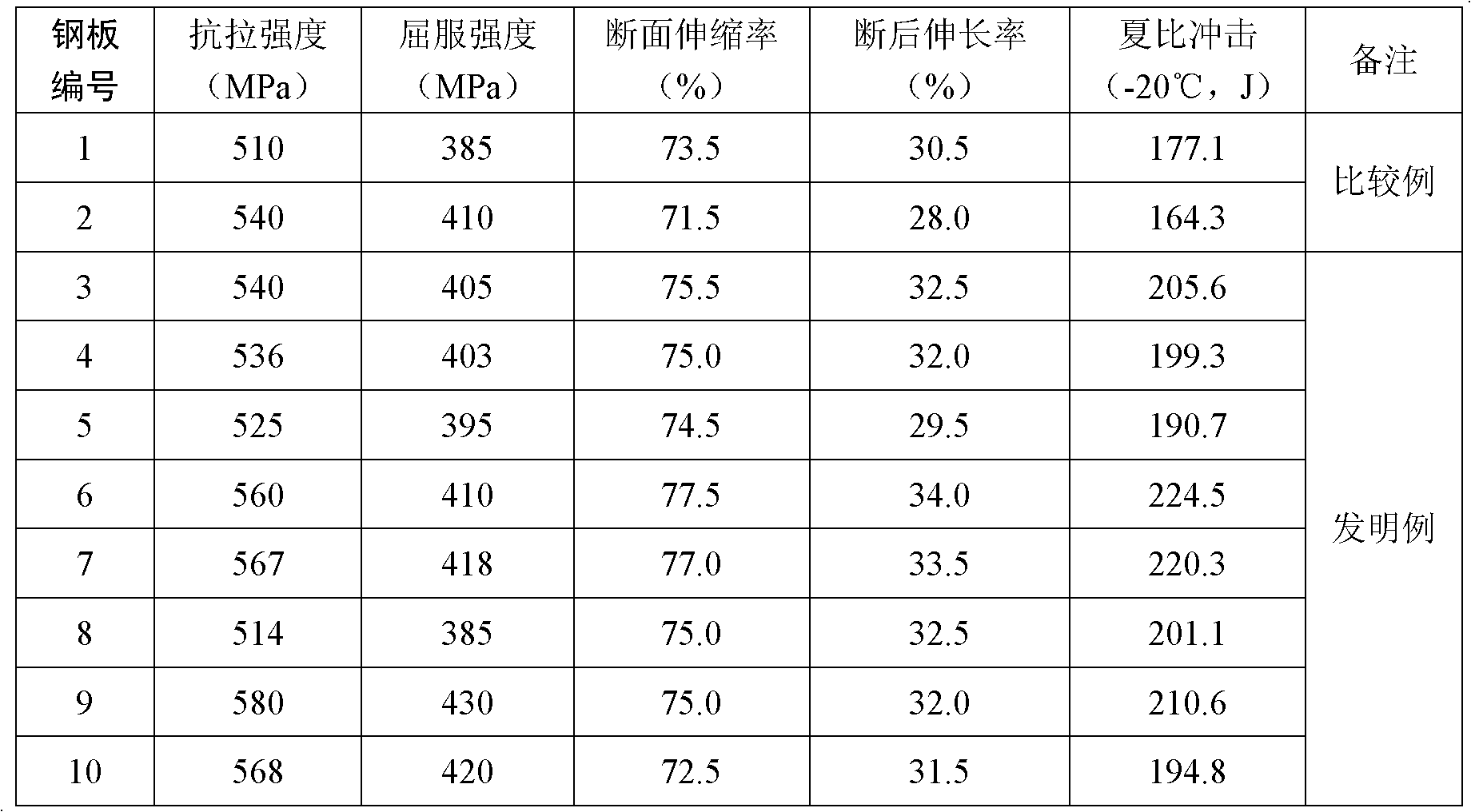

[0039] This test is an accelerated corrosion coupon test in the laboratory to simulate the steel surface in high concentration Cl - , The expansion rate of localized corrosion in high acidity environment. For each of the above-mentioned 50mm (length) × 25mm (width) × 5mm (thickness) square samples of each of the 5 pieces, each surface of the sample is polished to 600#, after cleaning with alcohol and acetone, measure the size of the sample and weight, test the two 50mm×25mm faces of the sample, and seal the other non-test faces with epoxy resin. The test solution is 10% NaCl aqueous solution, the pH value is adjusted to 0.6 with HCl, the test temperature is 40° C., and the soaking time is 72 hours. After the test, the corrosion products were removed, the corrosion weight loss was measured, and the corrosion rate was evaluated. The test results are shown in Table 3.

[0040]

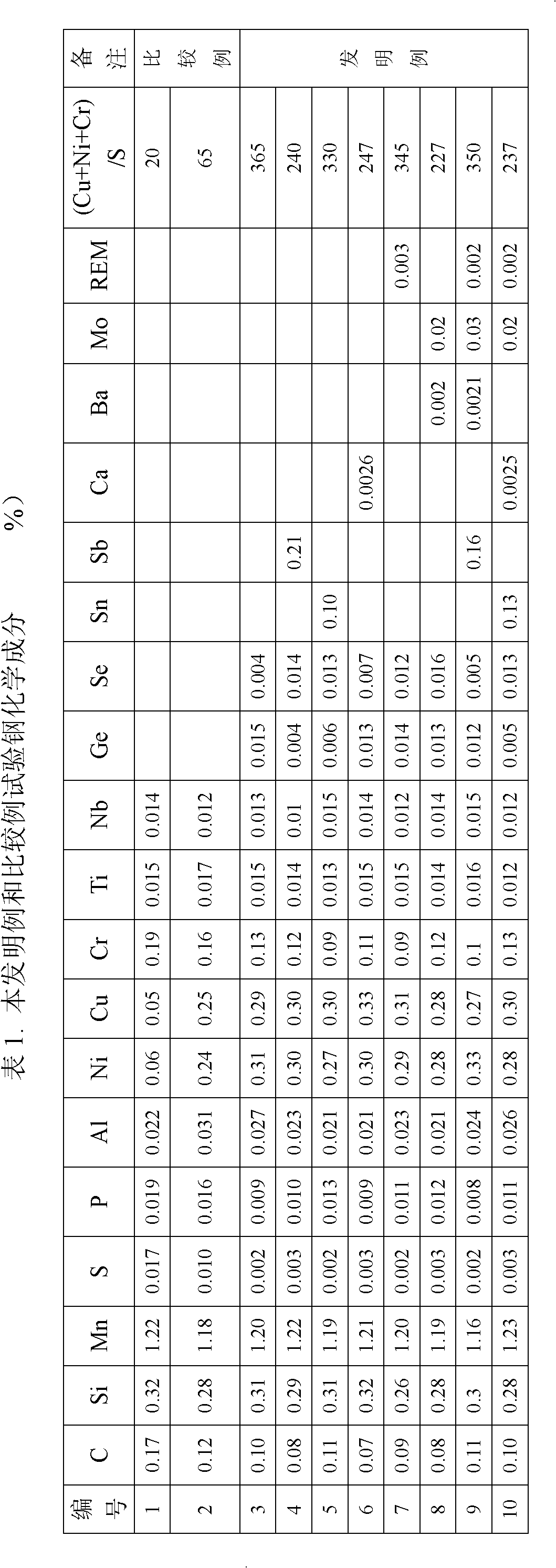

[0041] Table 2. Examples of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com