Anti-mildew treatment construction method for underground space latex paint engineering

A construction method and technology of latex paint, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve problems such as difficult-to-control latex paint mildew, latex paint prone to mildew, poor space ventilation, etc., to achieve extremely easy solution Mildew occurs, strong adhesion, simple material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

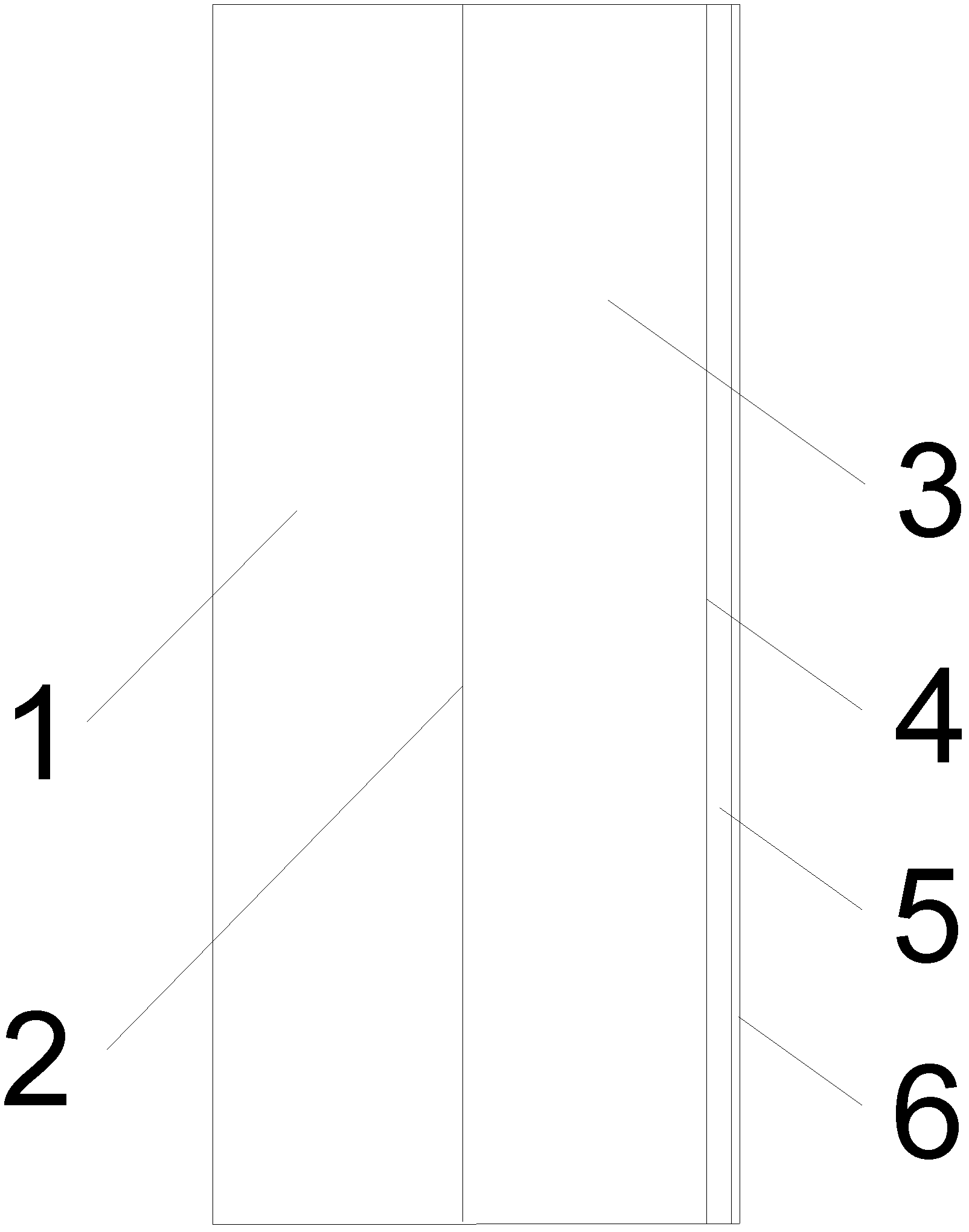

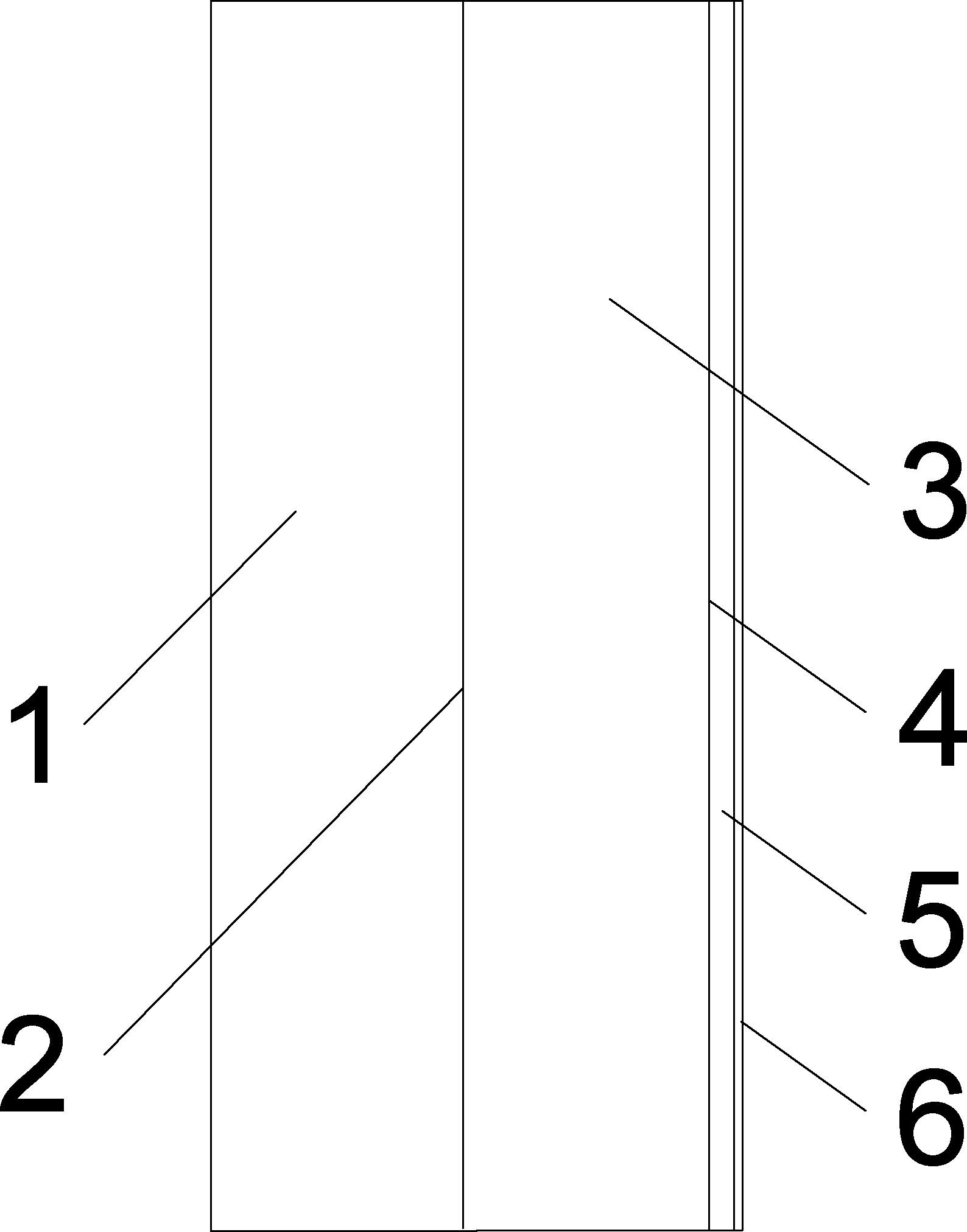

[0034] like figure 1 Shown, 1, a kind of underground space latex paint engineering anti-mildew treatment construction method described in the embodiment of the present invention may further comprise the steps:

[0035] Step 1: Back cover and leveling of the base layer: After cleaning the base layer of the building structure and local inspection and sealing treatment, use 801 glue to seal the bottom layer as a whole to form the bottom layer with 801 glue, and then level it with cement mortar to form a cement mortar leveling layer. The flatness must reach the level of cement Mortar screed layer acceptance criteria;

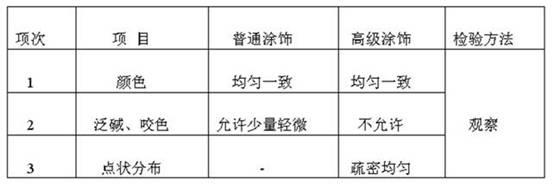

[0036] Among them, the thickness of the 801 glue seal bottom layer is 0.5-1mm; the cement mortar is made by mixing cement, yellow sand and 801 glue at a volume ratio of 1:2.5:0.3; the thickness of the cement mortar leveling layer is 20-40mm; the acceptance criteria for the cement mortar leveling layer The details are as follows:

[0037] item project ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com