On-line environment high-temperature test chamber for aviation kerosene hydraulic pump

A technology of high-temperature test chamber and aviation kerosene, which is applied in the direction of pump testing, liquid displacement machinery, machine/engine, etc., can solve the problems of harshness and strict test environment, and achieve the effect of fast temperature rise rate and large temperature rise rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

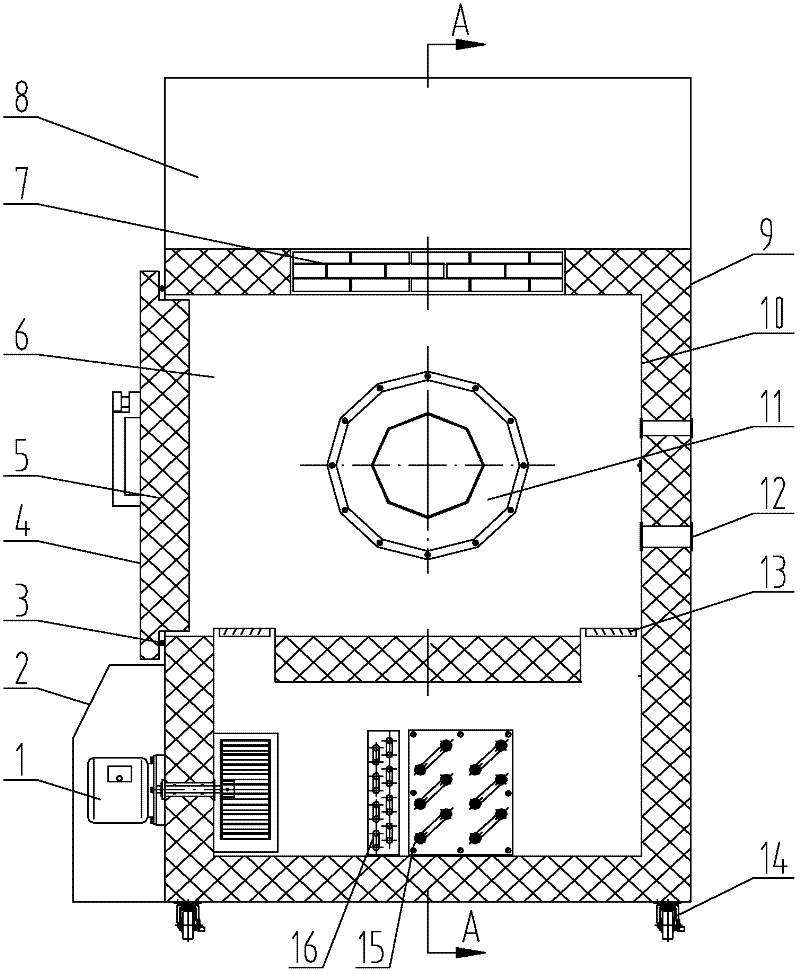

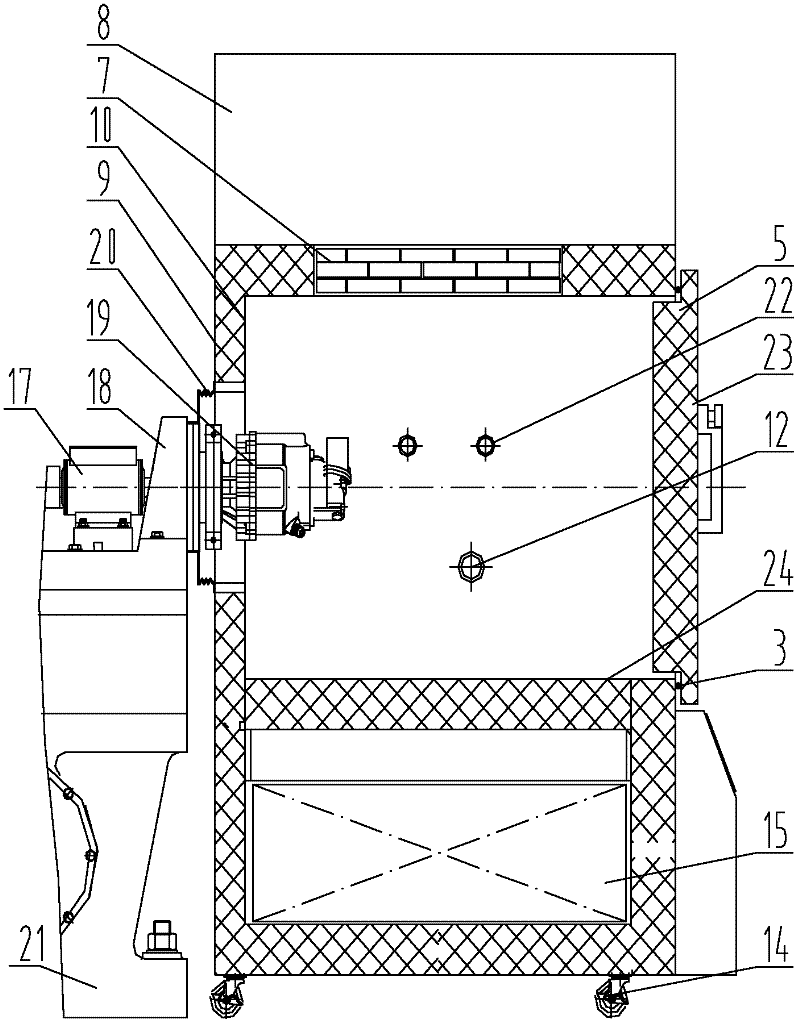

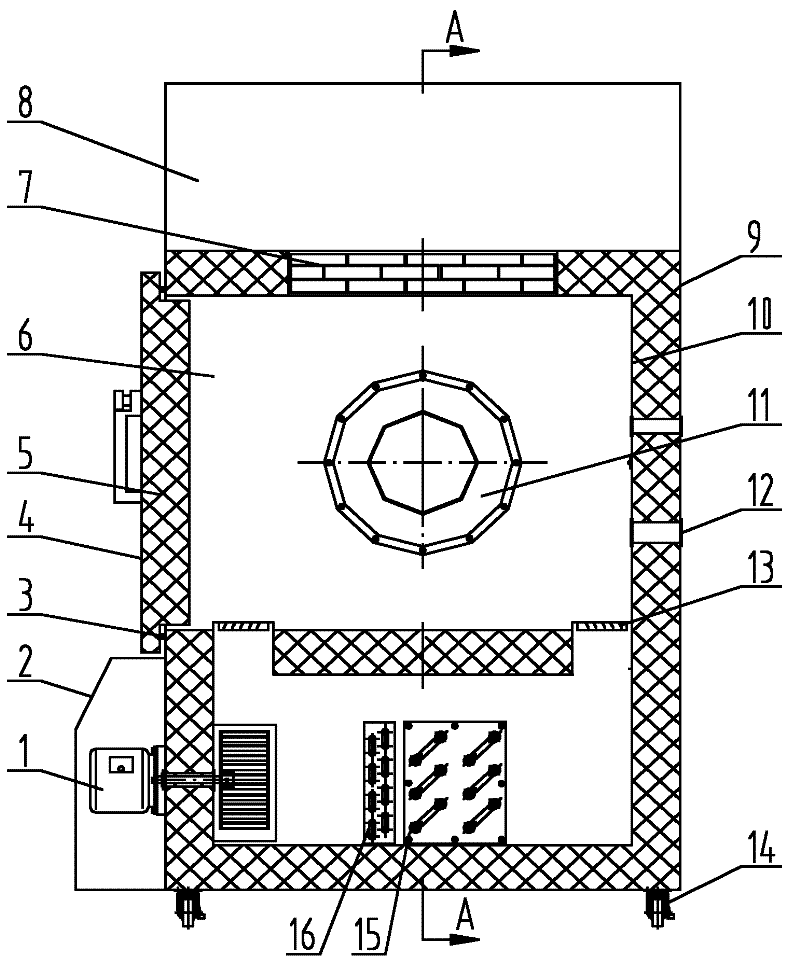

[0021] Example. An aviation kerosene hydraulic pump online environment high temperature test box, such as figure 1 and figure 2 as shown, figure 2 yes figure 1 The A-A cross-sectional view of A-A is also a schematic diagram of the installation structure, including a box body 24; a working room 6 is arranged inside the box body 24, and the working room 6 is connected to the test bench 21 through the pipeline interface A12, and the upper part of the box body 24 is provided with a pressure relief door 7 for pressure relief. An explosion vent box 8 is arranged above the door 7; an explosion-proof heater 15, an explosion-proof fan 1 and a water cooler 16 are arranged side by side at the lower part of the box body 24; The tested product 19 is fixed in the working chamber 6 through the transmission head 18 of the transmission device 17 . The explosion-proof fan 1 is covered with an instrument panel 2; the upper part of the instrument panel 2 is provided with a side door 4. A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com