Automatic weapon with rotary double chambers

A technology of automatic weapons and chambers, applied in the field of automatic weapons, can solve problems such as technical solutions that have not yet been found, and achieve the effects of simple structure, simplified structure, and increased firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

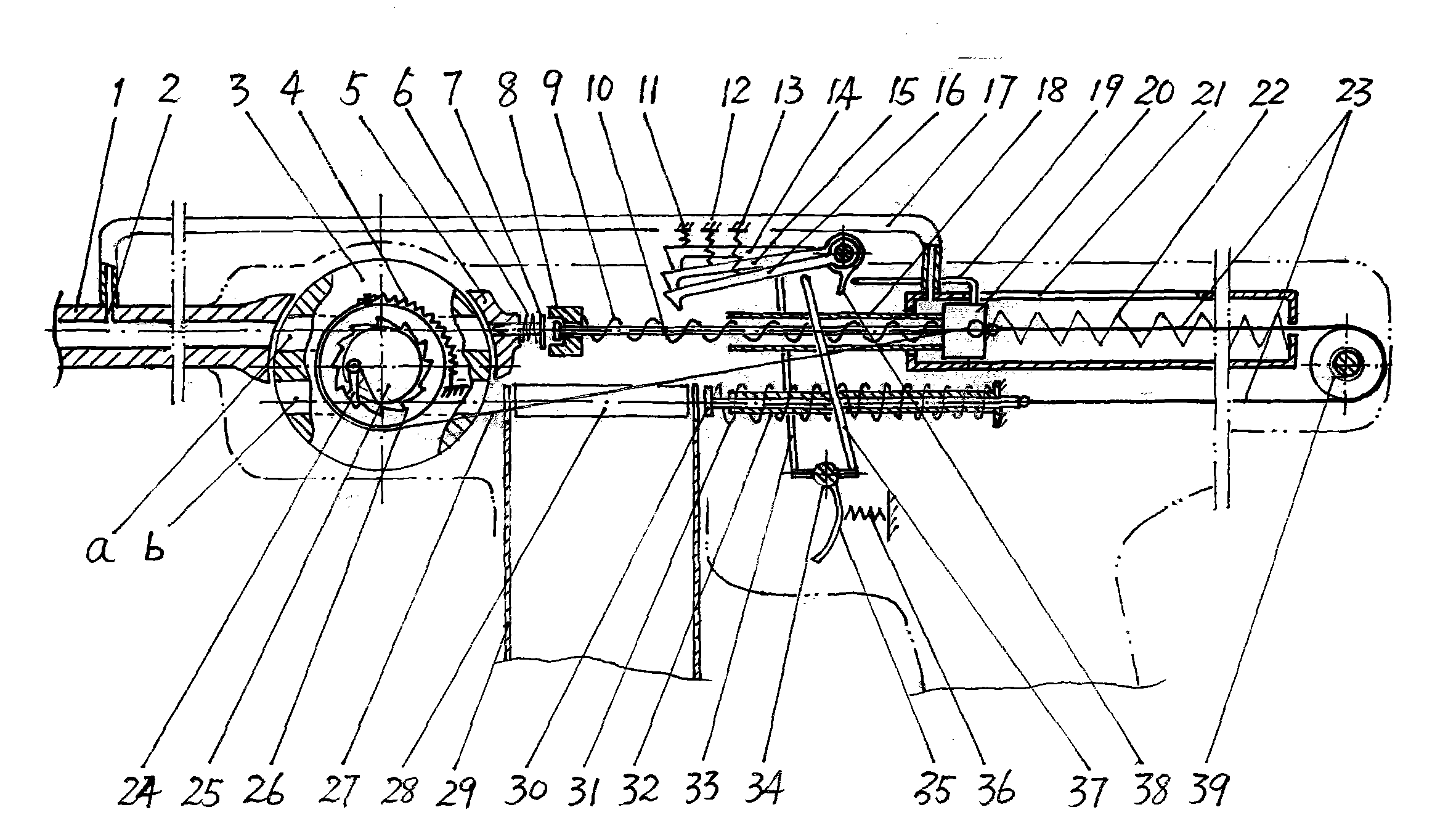

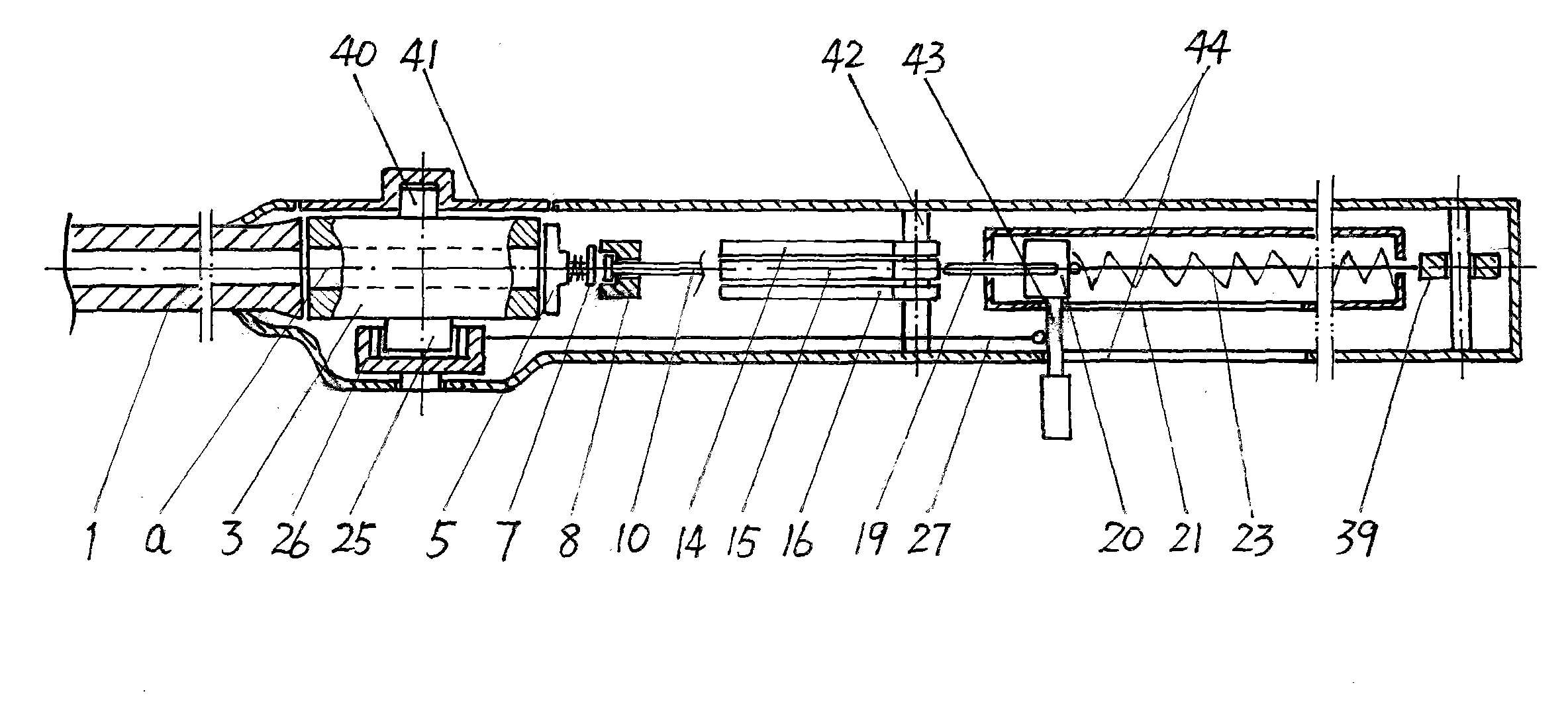

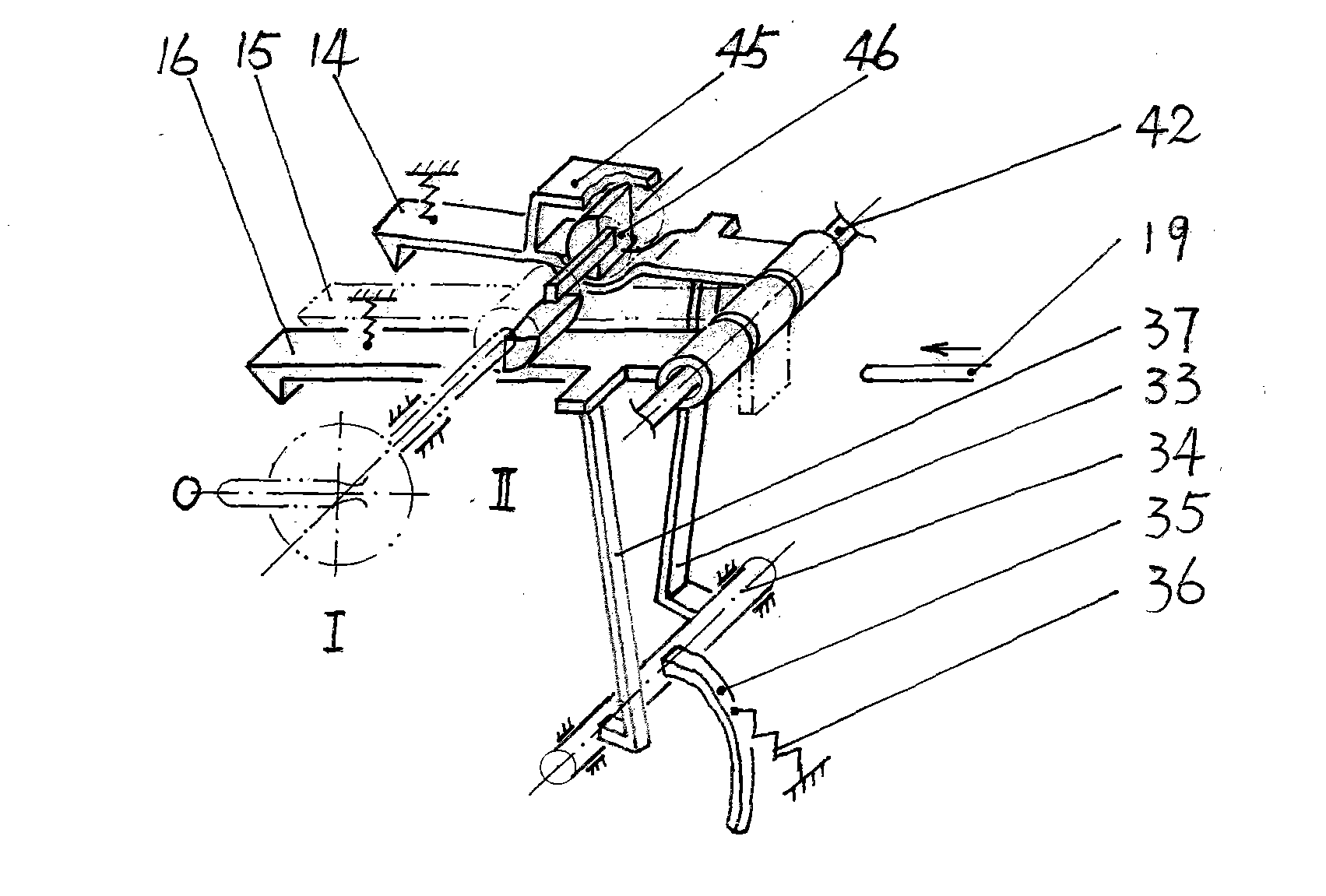

[0022] Example: such as figure 1 , figure 2 As shown, the rotary double chamber automatic weapon of the present invention, the tail end of the gun barrel 1 is provided with a rotating shaft and a cylindrical rotating chamber body 3 that is perpendicular to the space of the gun barrel, and two bullet chambers a and b parallel to the radial direction are arranged in it. , the rotating shaft 40 on one side of the rotating bullet chamber body is supported on the bullet chamber cover plate 41, the diameter of the bullet chamber cover plate is greater than the diameter of the rotating bullet chamber body, and it is articulated on the casing 44 and can be unloaded, and the other side is provided with The rotating shaft 25 of the ratchet 24 is supported on the ratchet 26, and is unidirectionally engaged with it. The ratchet is supported on the casing and has a ratchet return spring 4. One end of the ratchet backguy 27 is affixed to the edge of the ratchet, and the other end is bypass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com