Photoelastic tester for particulate matters

A technology of particulate matter and test instrument, which is applied in instruments, scientific instruments, and measurement of force by measuring the change of optical properties of materials when they are stressed. , the effect of high promotion value and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

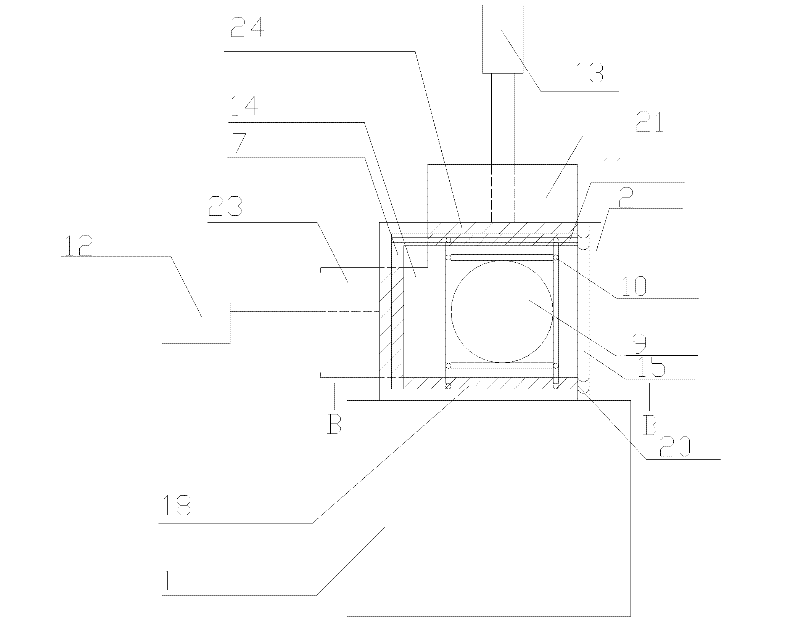

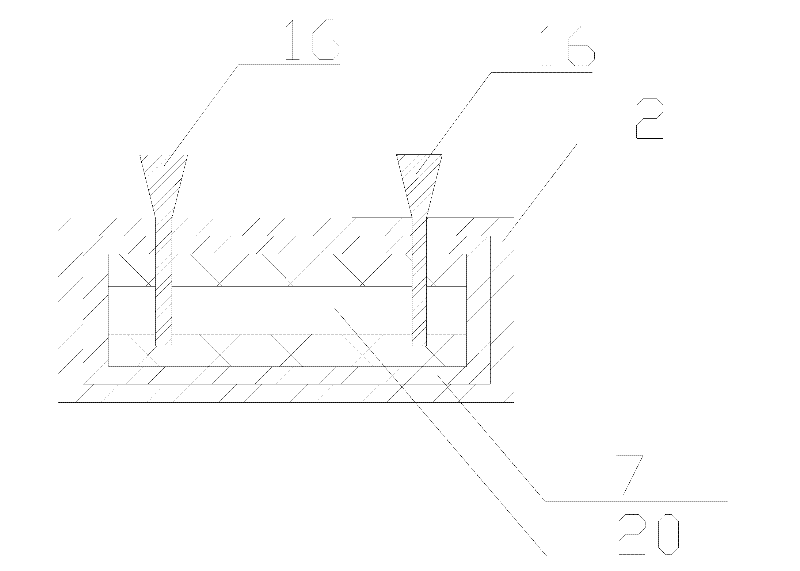

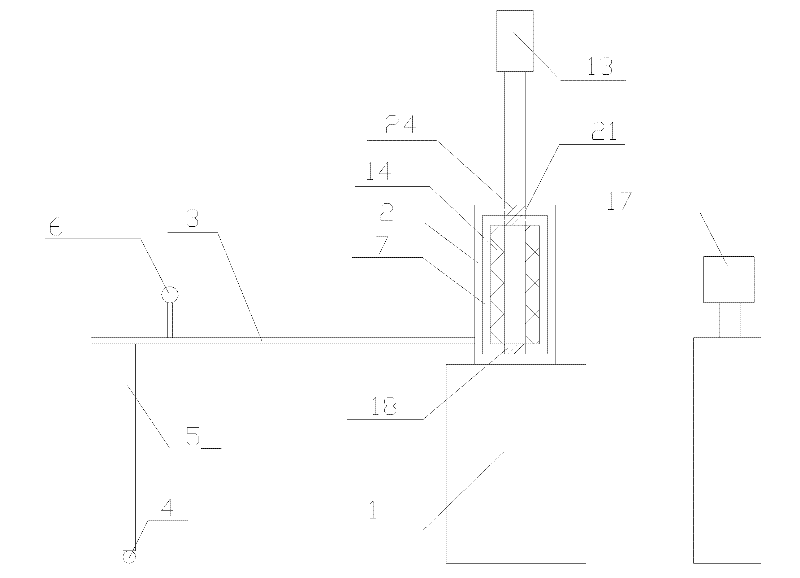

[0019] like figure 1 and image 3 As shown, the present invention is a photoelastic tester for particulate matter, including a cabinet 1, on which is a bearing frame 2, the bearing frame 2 consists of an upper steel plate 21, a lower steel plate 22, a left steel plate 23 and a right vertical column 15 Composition, one end of the upper steel plate 21 and one end of the lower steel plate 22 are connected to the left steel plate 23, the other end of the upper steel plate 21 and the other end of the lower steel plate 22 are connected to the vertical cylinder 15, and the upper steel plate 21 and the left steel plate 23 are connected with the loading steel plate 8. Consistently dimensioned openings 24. A horizontal sliding bracket 3 is fixedly connected to the bearing frame 2 , and the horizontal sliding bracket 3 is supported by a steel column 5 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com