Method for automatic measurement and morphological classification statistic of ultra-fine grain steel grains

An ultra-fine grain, automatic measurement technology, applied in the direction of measurement device, particle size analysis, particle and sedimentation analysis, etc., can solve the subjective error, occupied labor cost, the quantitative relationship of steel composition, structure, structure and performance is difficult to accurately establish and other problems to achieve excellent universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

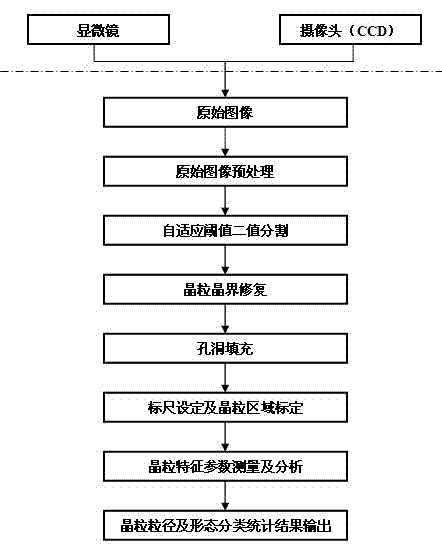

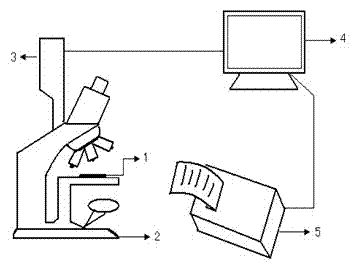

[0055] Use the image acquisition system to obtain the original grain image of the steel. The hardware of the image acquisition system is as follows: figure 2 Shown: steel sample 1, professional microscope 2, camera (CCD) 3, computer (interpolated image acquisition card) 4, printer 5. The specific steps of image acquisition are to use a microscope to adjust the image to a suitable focal length, take a picture when the image is clearest and store it in the image acquisition card (original image) before image preprocessing can be performed.

[0056] The original image of embodiment 1 is as image 3 shown. right first image 3 The original image is preprocessed. First, the image is denoised by median filtering. Then, use the histogram equalization algorithm that can preserve the image details to enhance the entire image to enrich the image detail information, so as to enhance the display effect of the image. In order to further extract the edge, the present invention utilize...

Embodiment 2

[0110] Such as Figure 11 The shown original metallographic image of ultra-fine grain steel with small grains and various shapes. The process of using the present invention to process it is as follows: first, the target image is preprocessed and the adaptive threshold segmentation algorithm based on area division is used for binary segmentation, and the processing effect is as follows: Figure 12 As shown; then the binary image is processed by boundary repair and intra-granular hole filling, and the processing effect is as follows Figure 13 As shown; set the scale and calibrate the area of each grain, measure and calculate the grain morphological characteristic parameters such as grain area, perimeter, aspect ratio, diameter, circularity and shape coefficient, and the grain size and shape Perform classification statistics. The grain size of embodiment 2, the classification statistical result of grain shape are respectively as follows Figure 14 a, 14b shown.

Embodiment 3

[0112] The present invention also has excellent grain measurement and classification effects on common steel products with a grain size of about 20 microns widely used in mechanical engineering, such as Figure 15 Metallographic raw image of plain steel shown with coarse grains. The process of using the present invention to process it is as follows: first, the target image is preprocessed and the adaptive threshold segmentation algorithm based on area division is used for binary segmentation, and the processing effect is as follows: Figure 16 As shown; then the binary image is processed by boundary repair and intra-granular hole filling, and the processing effect is as follows Figure 17 As shown; set the scale and calibrate the area of each grain, measure and calculate the grain morphological characteristic parameters such as grain area, perimeter, aspect ratio, diameter, circularity and shape coefficient, and the grain size and shape Perform classification statist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com