Method for detecting non-anode effect CF4

A detection method and anode effect technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of unable to detect non-anode effect, difficult to detect non-anode effect spectrum, affecting the detection accuracy of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

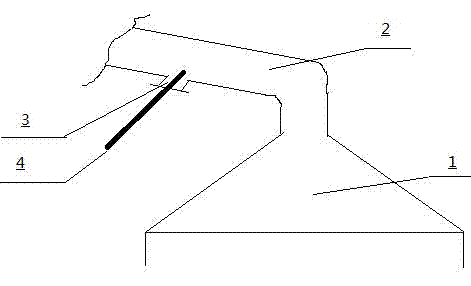

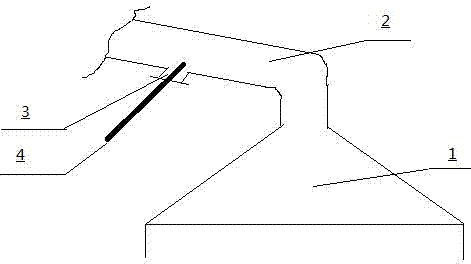

[0029] Set the PFC detection sampling point 3 on the cigarette pipe 2 of a certain 400kA electrolytic cell 1, insert the flue gas sampling pipe 4 (as attached figure 1 shown); connect the detection equipment, moisture filter, dust filter, sampling tube, sampling pump, monitoring computer; start the detection equipment, set the maximum CF of the detection equipment 4 The standard spectrum is 1ppmv, calibrate the zero point of the equipment, adjust the flue gas flow into the detection equipment; monitor the voltage change of the electrolytic cell, when the cell voltage exceeds the normal operating voltage by 50 millivolts, start detection and record CF 4 During the test period, keep the tank cover in an airtight state, and the gas collection efficiency of the electrolyzer flue gas should not be lower than 90%. After continuous detection for 6 hours, CF was detected 4 The average concentration of 0.707ppmv.

Embodiment 2

[0031] Set the PFC detection sampling point 3 on the cigarette pipe 2 of a certain 300kA electrolytic cell 1, insert the flue gas sampling pipe 4 (as attached figure 1 shown); connect the detection equipment, moisture filter, dust filter, sampling tube, sampling pump, monitoring computer; start the detection equipment, set the maximum CF of the detection equipment 4 The standard spectrum is 1ppmv, calibrate the zero point of the equipment, adjust the flue gas flow into the detection equipment; monitor the voltage change of the electrolytic cell, when the cell voltage exceeds the normal operating voltage by 50 millivolts, start detection and record CF 4 During the test period, keep the tank cover in an airtight state, and the gas collection efficiency of the electrolyzer flue gas should not be lower than 90%. After 9 hours of continuous detection, CF was detected 4 The average concentration of 0.516ppmv.

Embodiment 3

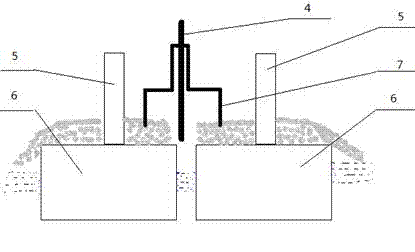

[0033] Set the PFC detection sampling point in the gas collecting hood 7 of the middle seam / side seam of the anode of a certain 200kA electrolyzer; connect the detection equipment, moisture filter, dust filter, sampling pipe, sampling pump, monitoring computer; start the detection equipment, set Determine the maximum CF of the testing equipment 4 The standard spectrum is 1ppmv, calibrate the zero point of the equipment, adjust the flue gas flow into the detection equipment; monitor the change of the anode current density of the electrolytic cell, when the current density of individual anodes 6 (connected by the guide rod 5) (one or several anodes) exceeds the normal Operating current density 0.5A / cm 2 , insert the flue gas sampling pipe 4 for sampling (as attached figure 2 shown), start detection, record CF 4 The volume concentration; if there are multiple anodes, multiple sampling points can be used to collect the gas together for detection. After 12 hours of continuous d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com