Failure analysis method

A failure analysis, a part of the technology, applied in the field of failure analysis, can solve problems such as poor effectiveness and low success rate of failure analysis work, and achieve strong accuracy and persuasion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

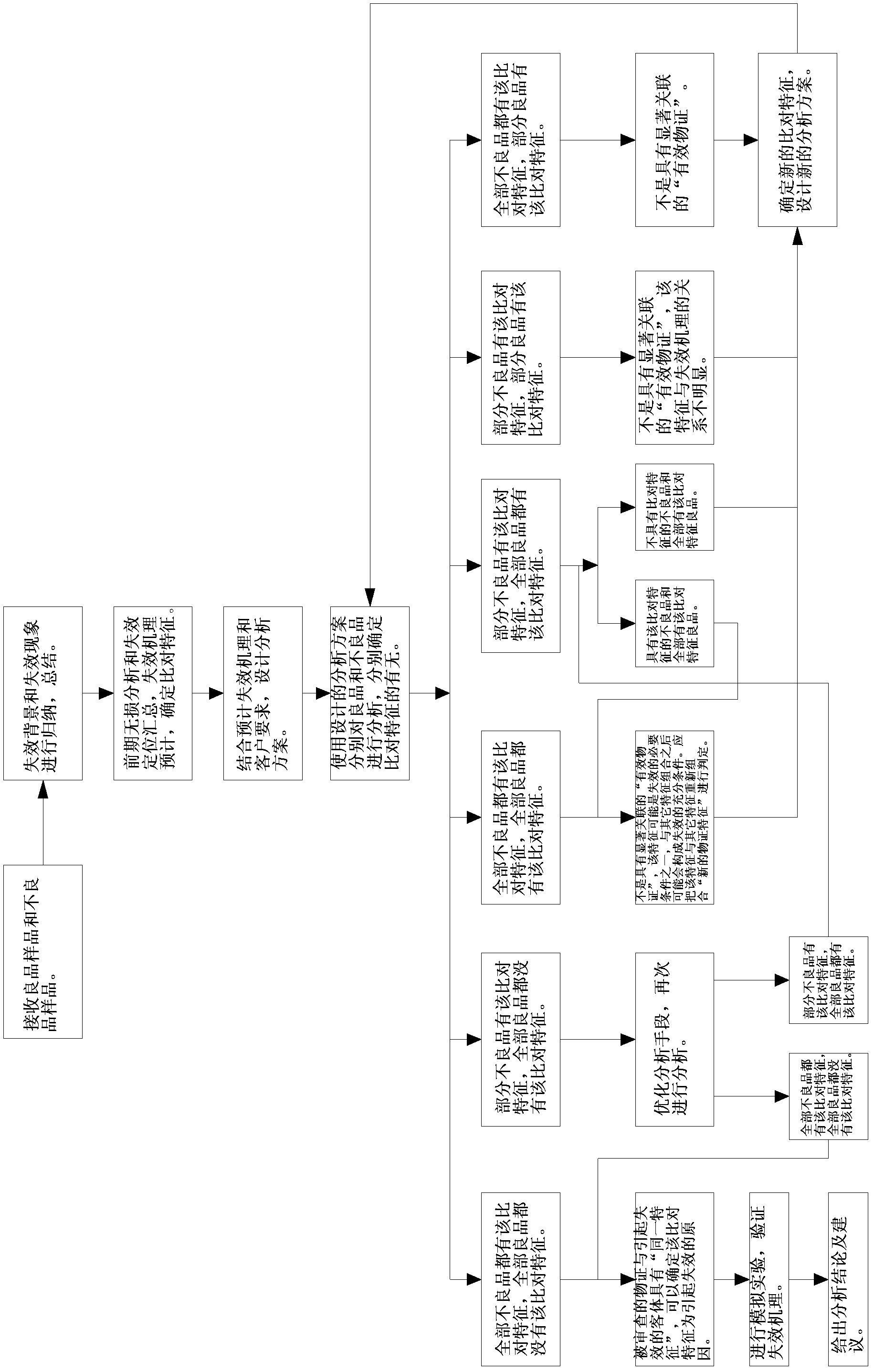

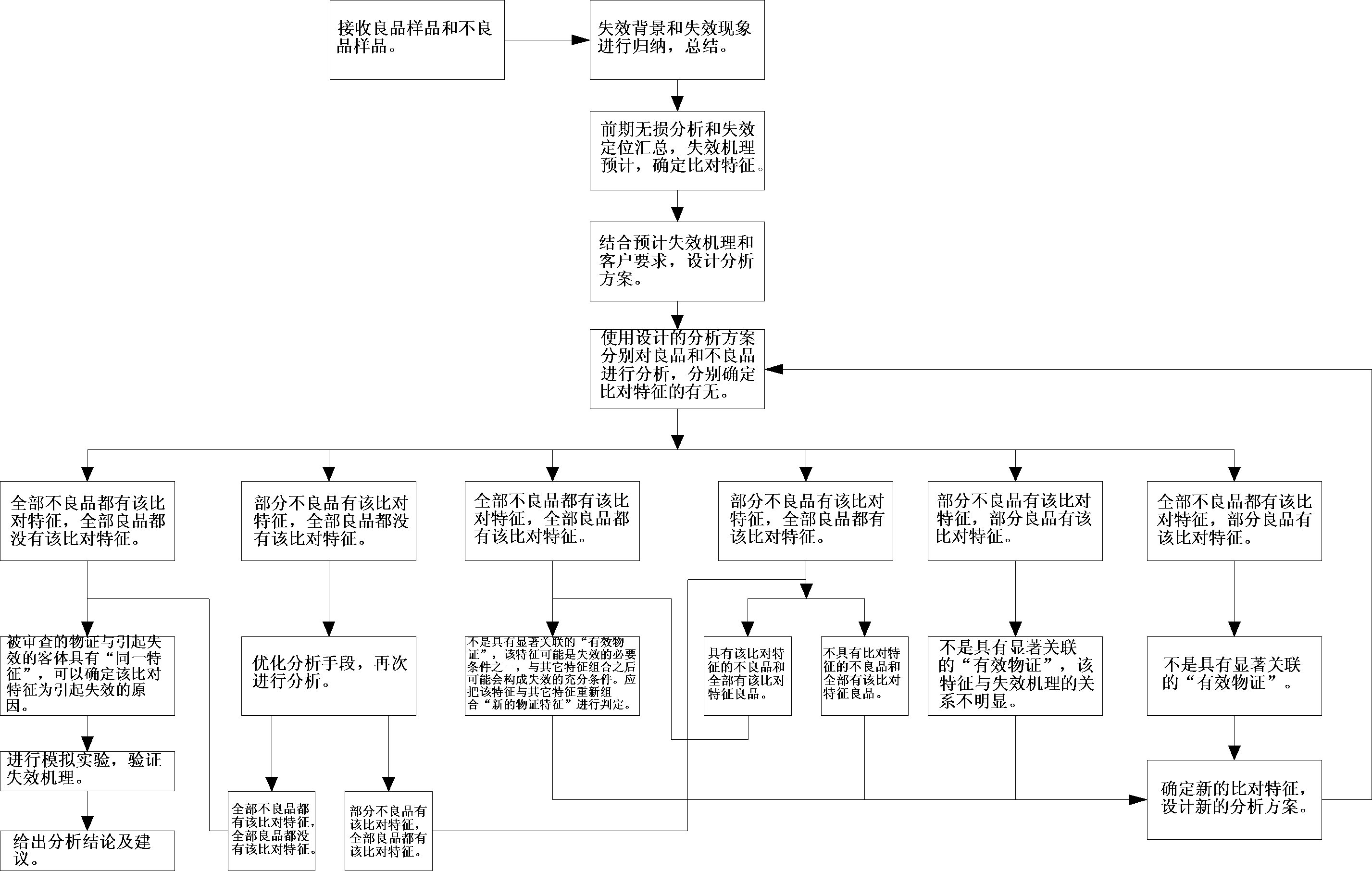

Method used

Image

Examples

Embodiment 1

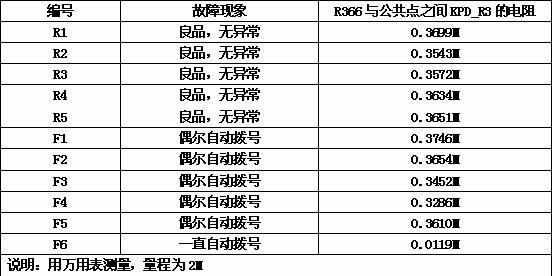

[0030] Example 1: A certain unit needs to conduct failure analysis on mobile phones with automatic dialing problems, and provides 6 defective samples (numbered F1~F6) and 5 reference samples (numbered R1~R5) respectively. Among the defective samples , The phenomenon of R6 is automatic dialing all the time, that is, the number 6, 7, and 8 keys automatically dial after the mobile phone is turned on, the sequence is uncertain, the frequency is uncertain, until the mobile phone is automatically shut down when the battery is out, and the defective product samples F1~F5 occasionally appear when testing. 6, 7, 8 keys automatically dial phenomenon.

[0031] Conduct preliminary non-destructive testing and failure location. Bake the defective samples in an environment of 85°C for 45 minutes, cool to room temperature, and after the mobile phone is powered on, the phenomenon of automatic dialing still exists, which shows that the factor of automatic dialing still exists. Remove the s...

Embodiment 2

[0044] Example 2: A certain unit requires failure analysis of the LED digital tube samples it provided. The unit provided a total of 12 samples, including 6 defective samples and 6 unused reference samples. The background of the failure is that after the LED digital tube has been packaged and stored for several months, there are defects when it is used by the client, which manifests as abnormal phenomena such as LED lights not lighting, broken codes, and garbled codes, with a defect rate of 11.7%.

[0045] Firstly, the non-destructive analysis was carried out in the early stage, and the appearance optical inspection was carried out on the defective product samples and the reference samples respectively, and no abnormal phenomenon was found; the electrical tests were carried out on the defective product samples and the reference samples respectively, and the tests showed that the I / V curves of the six defective product samples were abnormal; Carried out X-ray detection, no a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com