Method for preparing large-area flexible conductive film

A flexible conductive, large-area technology, applied in the field of flexible electronics, can solve the problems of poor stretchability, poor film conductivity, film cracking, etc., and achieve the effects of avoiding damage, excellent stretchability and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

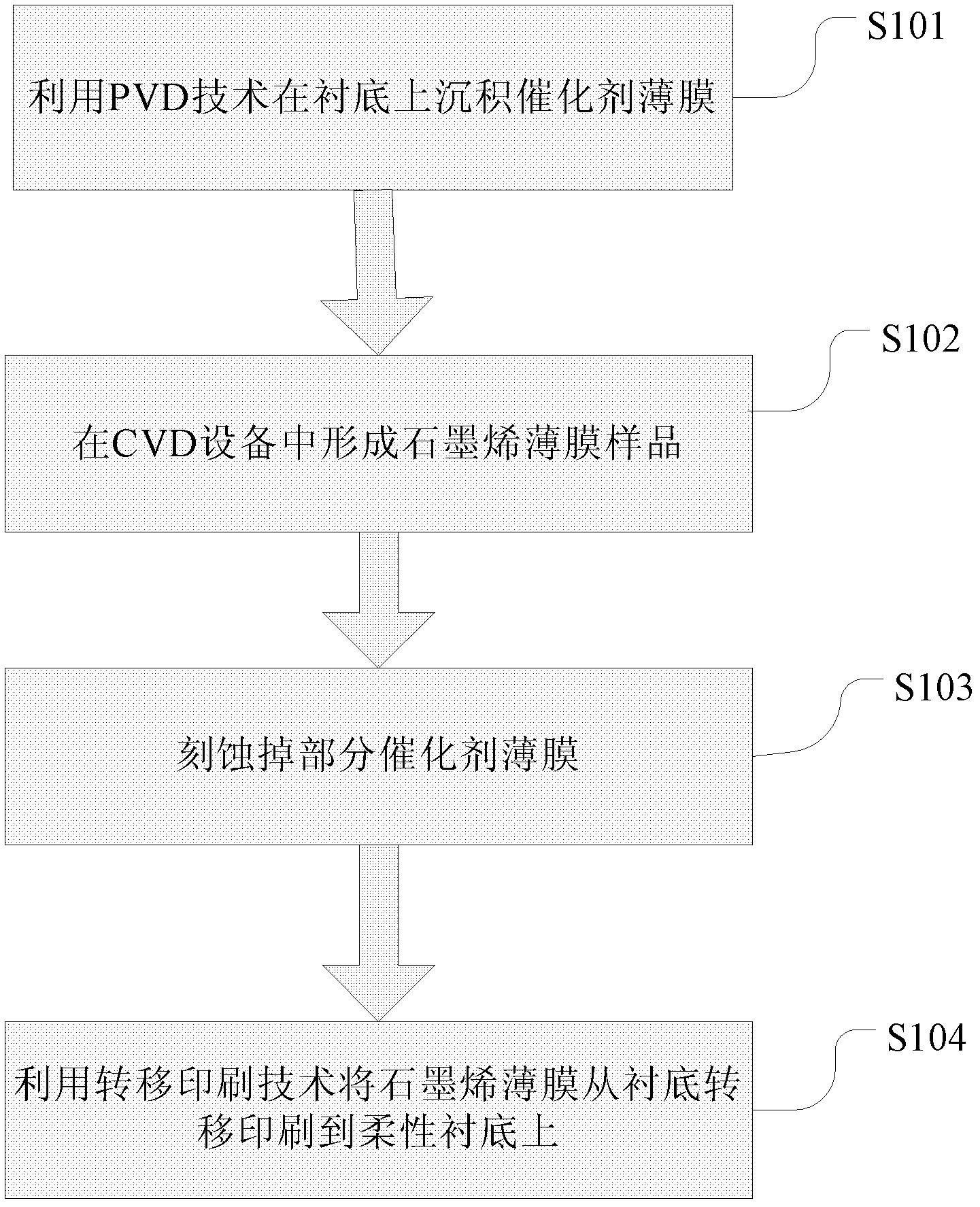

[0035] Such as figure 1 As shown, a method for preparing a large-area flexible conductive film includes the following steps: In step 101, a layer of SiO is formed on the Si sheet 2 Form the substrate, and use PVD technology to deposit a catalyst film on the substrate;

[0036] In step 102, the substrate on which the catalyst thin film is deposited is placed in a CVD device, and a large flow of Ar and H 2 gas, while rapidly raising the CVD temperature to 800°C, and then passing CH 4 Gas, after a few minutes, close the CH 4 The gas valve quickly cooled the CVD equipment to room temperature, and obtained the graphene film sample;

[0037] In step 103, the graphene film sample is placed in an etchant, and part of the catalyst film is etched away;

[0038] In step 104, the graphene film is transferred from the substrate to the flexible substrate by transfer printing technology.

[0039] Among them: PVD technology is electron beam evaporation or sputtering. The catalyst is Ni ...

Embodiment 2

[0047] In step 102 of Embodiment 1, the substrate on which the catalyst thin film is deposited is placed in a CVD device, and a large flow of Ar and H 2 gas while rapidly raising the CVD temperature to 900°C.

Embodiment 3

[0049] In step 102 of Embodiment 1, the substrate on which the catalyst thin film is deposited is placed in a CVD device, and a large flow of Ar and H 2 gas, while rapidly raising the CVD temperature to 1000°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com