Power supply for portable equipment as well as lithium ion battery of power supply and lithium ion battery package casing

A technology for lithium-ion batteries and packaging shells, applied in battery circuit devices, secondary batteries, circuit devices, etc., can solve problems such as electrolyte leakage, poor sealing performance of outer packaging bags, affecting battery appearance and cycle life, etc. , to achieve the effect of high mechanical hardness, easy replacement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

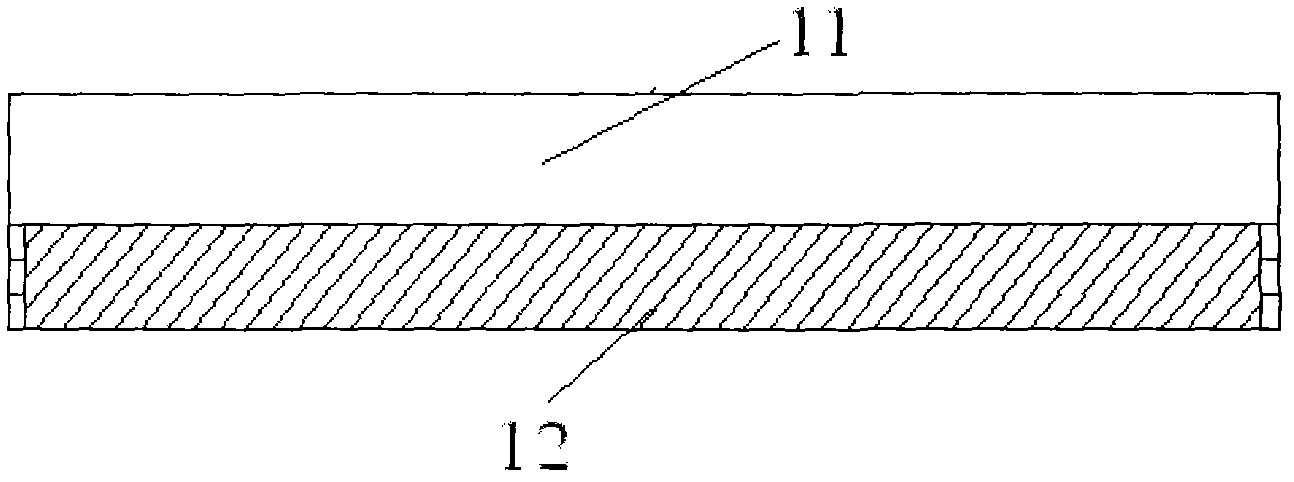

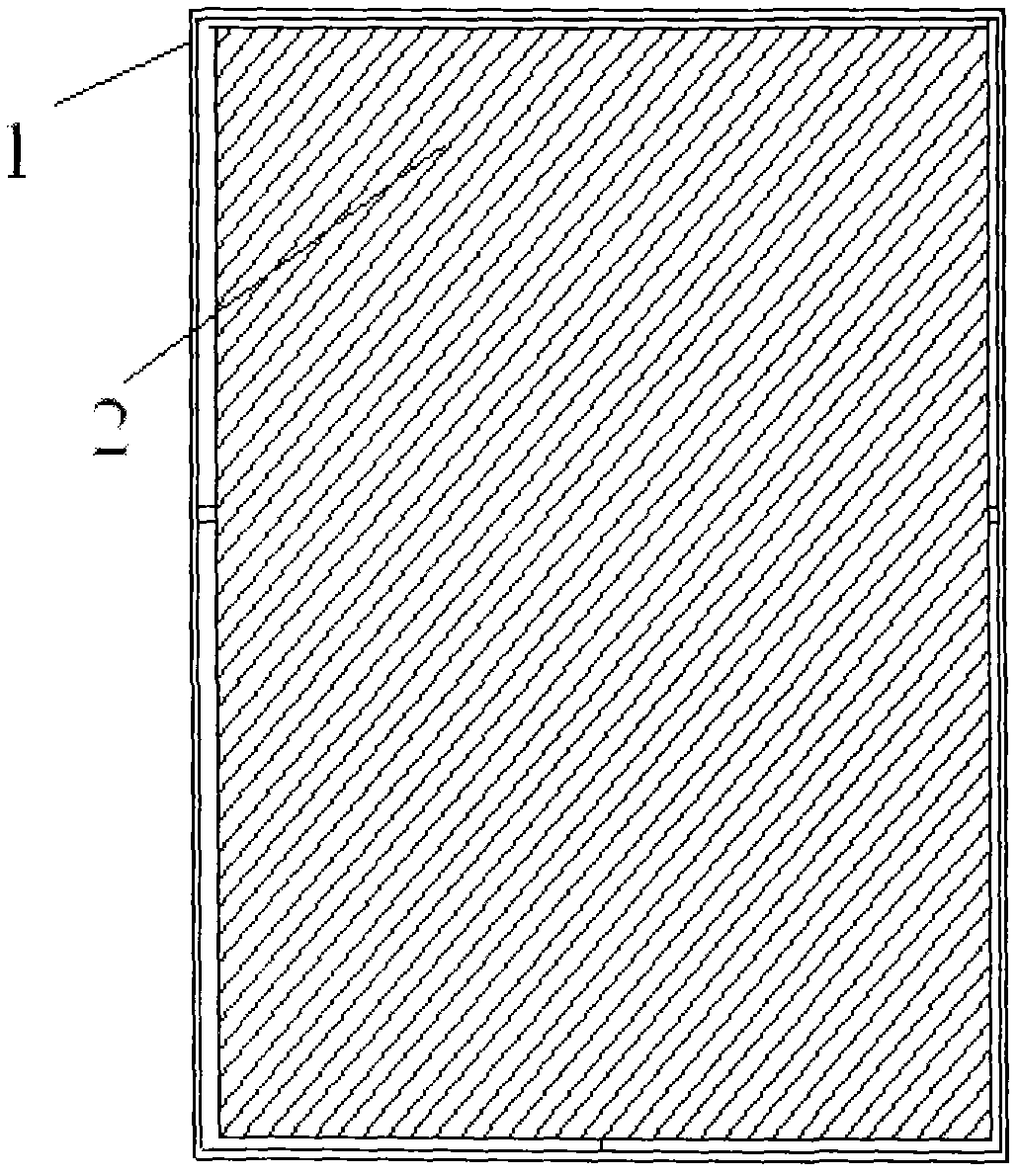

[0027] The plastic structure layer 12 is made of polyethylene terephthalate (PET). According to the shape and size of the battery core 2, the polyethylene terephthalate is processed into a cavity with a thickness of 30um by injection molding. , and then put the lithium-ion battery 01 into the cavity in a dry room, inject liquid, seal and activate. Then vacuum aluminum plating is performed on the outer surface of the cavity to obtain a vacuum metallization (aluminum) layer 11, the thickness of the aluminum plating is 5um, and the packaging case 1 packaged outside the lithium ion battery 01 is obtained.

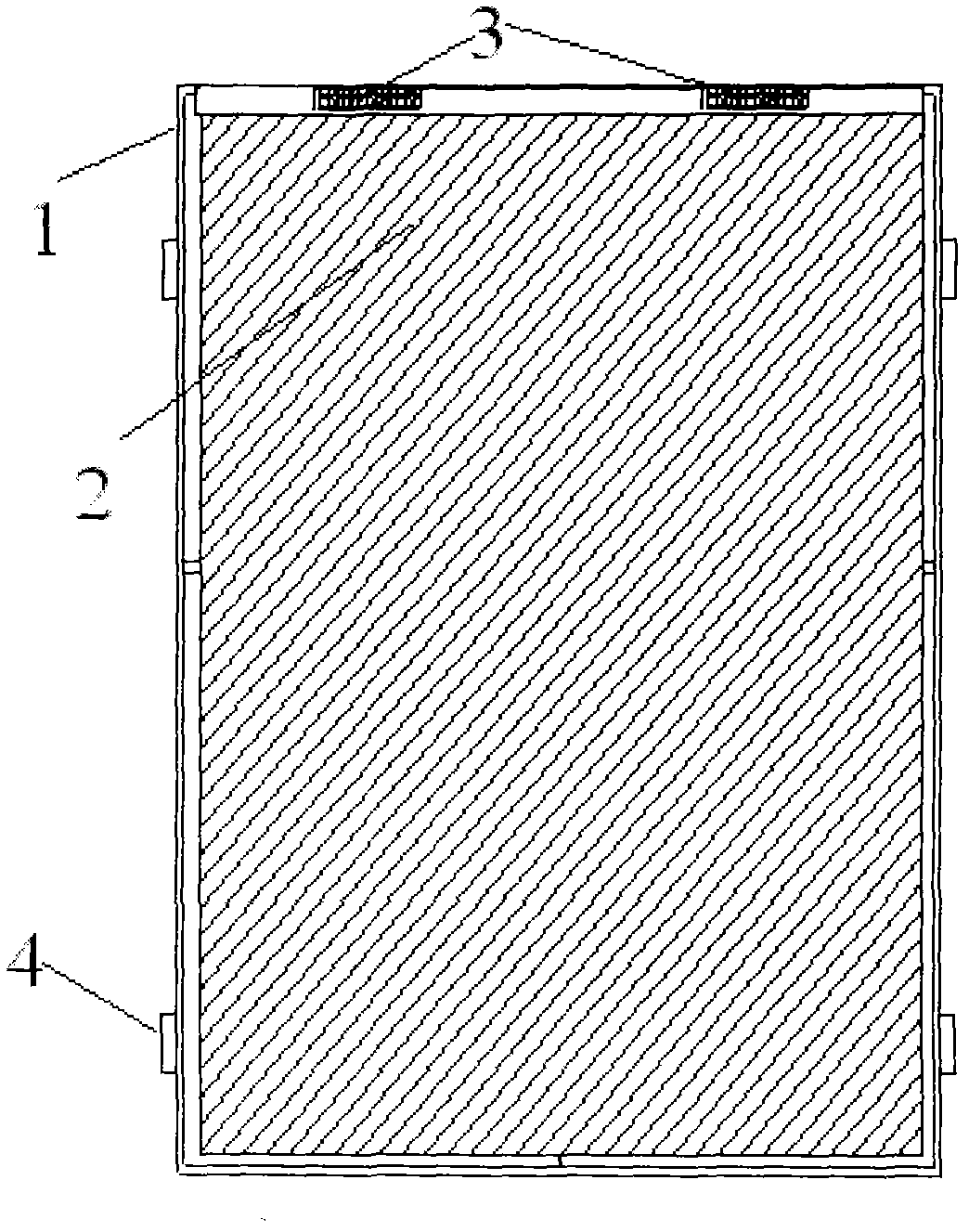

[0028] Then, the lug part of the obtained lithium ion battery 01 is welded to the circuit board 3, and then the mechanical buckle 4 is fastened around the lithium ion battery 01 to obtain a power supply for portable equipment. The packaging case 1 of the lithium-ion battery 01 can be directly used as the outer protective case of the portable device.

Embodiment 2

[0030] The difference from Example 1 is that the plastic structure layer 12 is made of polyethylene naphthalate (PEN) with a thickness of 50 um, and the vacuum metallization layer is a vacuum tin-plated layer with a thickness of 6 um.

[0031] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] The difference from Example 1 is that the plastic structure layer 12 is polyphenylene resin (PHB) with a thickness of 90 um, and the vacuum metallization layer is a vacuum tin-plated layer with a thickness of 7 um.

[0034] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com