Syringe type atmospheric-pressure micro-plasma generator

A micro-plasma and injector-type technology, which is applied in the direction of plasma and electrical components, can solve the problems of restricting the development of plasma application technology, high plasma gas flow rate, and staying in the processing range, so as to achieve simple discharge mode and high gas flow rate. The effect of low cost and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

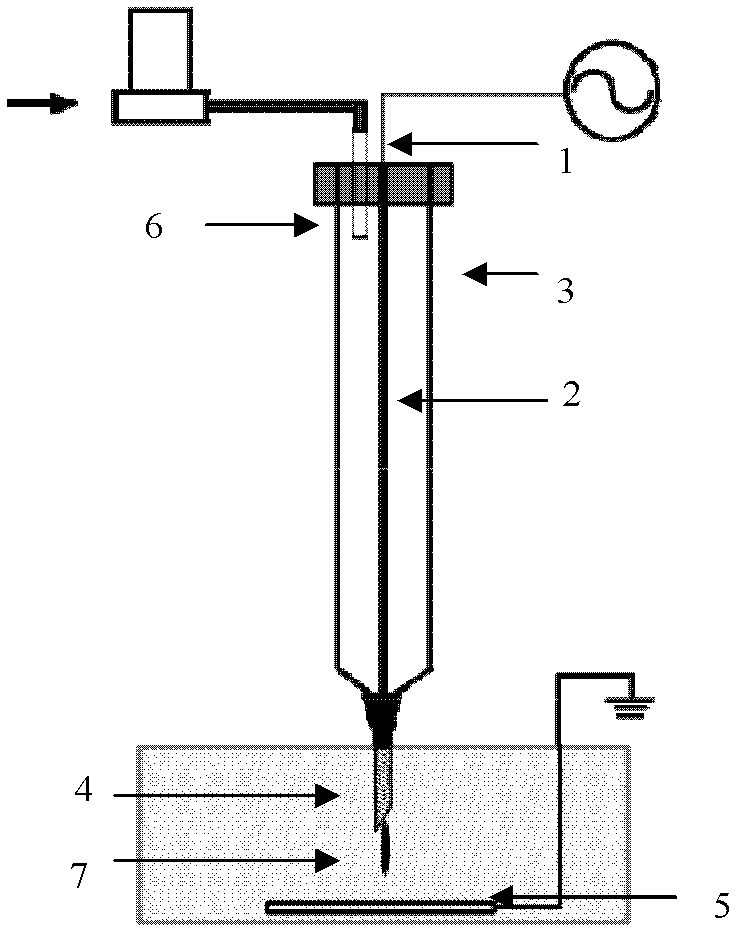

[0023] A syringe type atmospheric pressure micro plasma generating device, such as figure 1 As shown, a copper core is used as the high-voltage electrode 1 and inserted into the micro-hole optical fiber 2 to connect to the AC high-voltage power supply. The upper end of the syringe 3 is closed and connected to the intake pipe 6. The optical fiber passes through the lower end of the syringe and is wrapped inside the ceramic needle 4. Copper sheets are used. Place the ground electrode 5 in the sample and ground it. Wherein, the outer diameter of the microporous optical fiber is 1 mm, and the inner diameter is 50 μm; the outer diameter of the ceramic needle is 1.6 mm, and the length is 30 mm; the diameter of the high-voltage electrode is 50 μm; the frequency of the high-voltage power supply is 5-15 KHz, Its peak-to-peak value is 6-35KV;

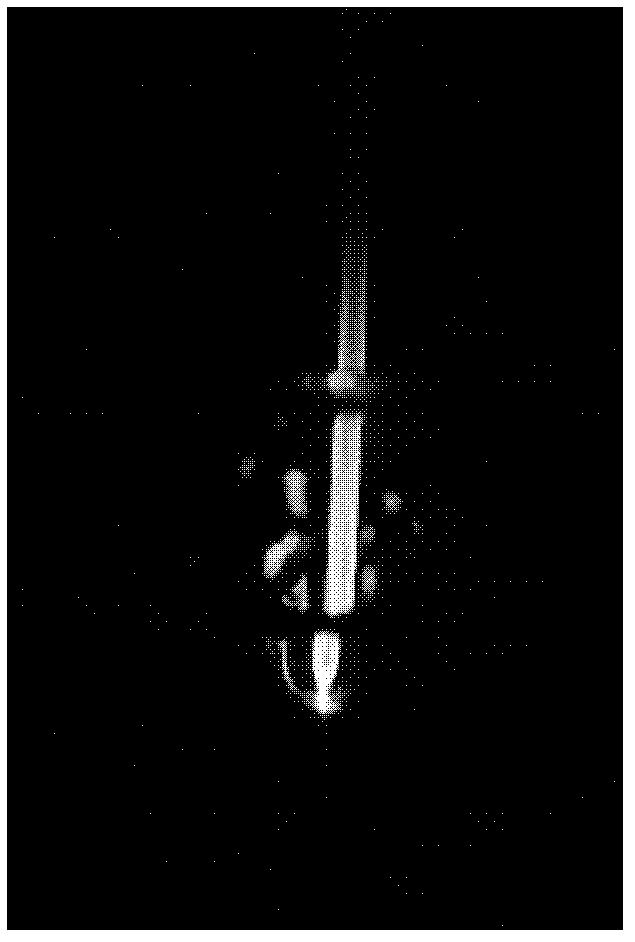

[0024] When discharging, the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com